Production technique of cool boiled water

A production process, cool and open technology, applied in water/sludge/sewage treatment, filtration treatment, heating water/sewage treatment, etc., can solve problems such as being unsuitable for mass production in factories, deviating from healthy routes, etc., to accelerate human metabolism, Eliminate the risk of bromate and have a good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

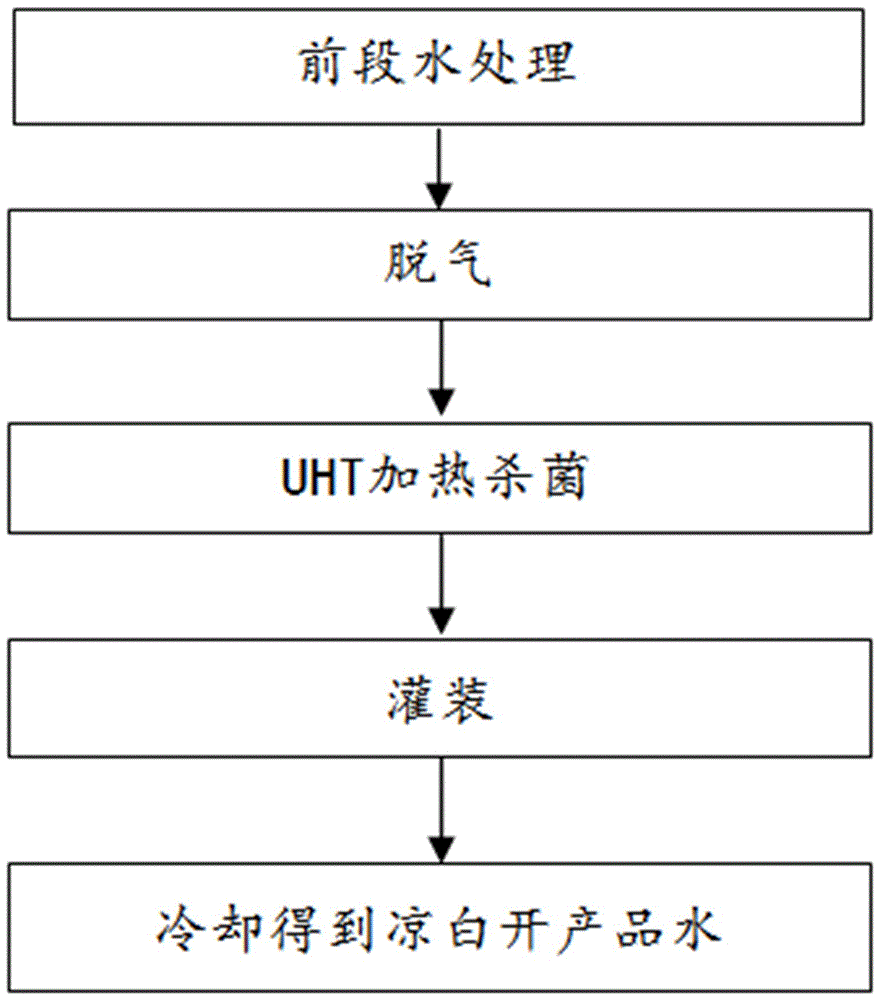

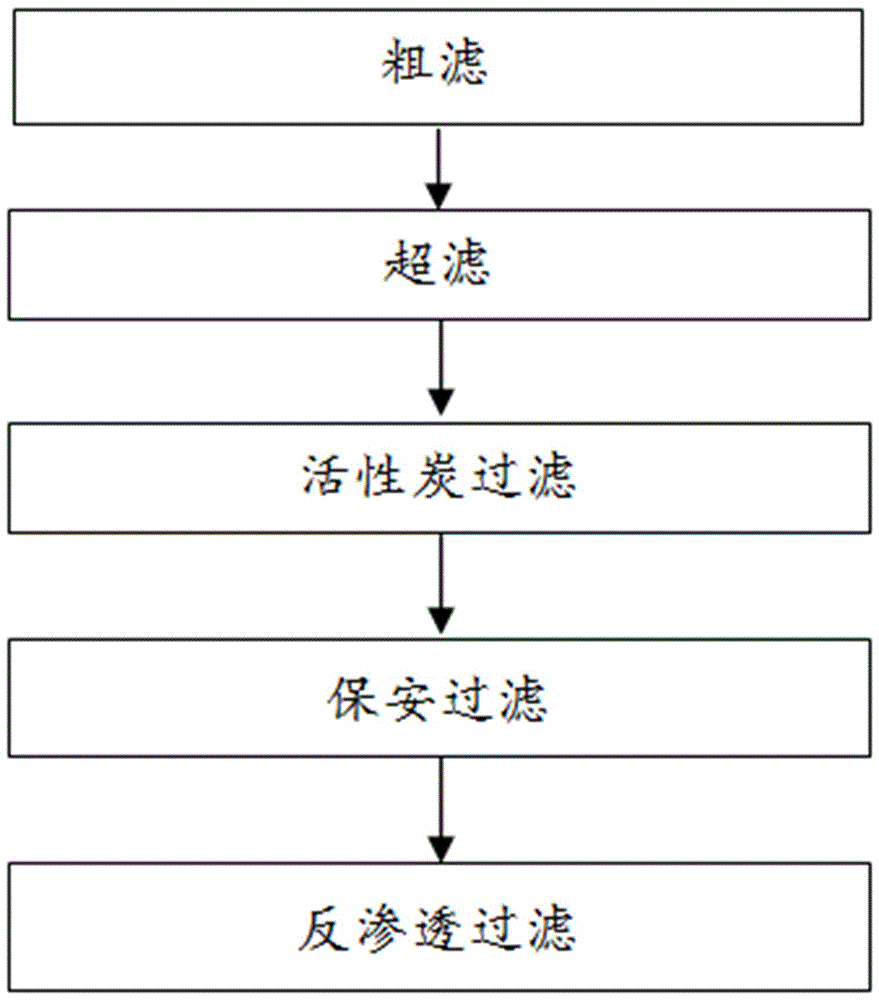

[0030] Such as figure 1 with figure 2As shown in the figure, a production process of cold boiled water is obtained. After the raw water is sequentially passed through laminated filter coarse filtration, ultrafiltration, activated carbon filtration, 5μm filter security filtration, and first-stage reverse osmosis filtration, the conductivity ≤ 50μs / cm and natural pH value are obtained. Clean water: the clean water obtained from the pre-treatment is degassed through the degassing tower, the degassing process temperature is 70°C, and the degassing process time is 1min to obtain degassed clean water; the degassed clean water is passed into the UHT sterilizer Carry out heat sterilization, the sterilization temperature is 125°C, and the temperature holding time is 10s; the water after UHT heat sterilization is introduced into the filling and capping machine to complete the filling, and the filling temperature is 75°C; the filled product is placed in a cold bottle The machine is div...

Embodiment 2

[0032] Such as figure 1 with figure 2 As shown in the figure, a production process of cold boiled water is obtained. After the raw water is sequentially passed through laminated filter coarse filtration, ultrafiltration, activated carbon filtration, 5μm filter security filtration, and first-stage reverse osmosis filtration, the conductivity ≤ 50μs / cm and natural pH value are obtained. Clean water: the clean water obtained from the pre-treatment is degassed through the degassing tower, the degassing process temperature is 70°C, and the degassing process time is 1min to obtain degassed clean water; the degassed clean water is passed into the UHT sterilizer Carry out heat sterilization, the sterilization temperature is 125°C, and the temperature holding time is 15s; the water after UHT heat sterilization is introduced into the filling and capping machine to complete the filling, and the filling temperature is 75°C; the filled product is placed in a cold bottle The machine is di...

Embodiment 3

[0034] Such as figure 1 with figure 2 As shown in the figure, a production process of cold boiled water is obtained. After the raw water is sequentially passed through laminated filter coarse filtration, ultrafiltration, activated carbon filtration, 5μm filter security filtration, and first-stage reverse osmosis filtration, the conductivity ≤ 50μs / cm and natural pH value are obtained. Clean water: the clean water obtained from the pre-treatment is degassed through the degassing tower, the degassing process temperature is 70°C, and the degassing process time is 1min to obtain degassed clean water; the degassed clean water is passed into the UHT sterilizer Carry out heat sterilization, the sterilization temperature is 125°C, and the temperature holding time is 10s; the water after UHT heat sterilization is introduced into the filling and capping machine to complete the filling, and the filling temperature is 80°C; the filled product is placed in a cold bottle The machine is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com