Recycled micro powder activation method

A technology of regenerated micropowder and activation method, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of environmental and personal safety hazards, immature research, deterioration of natural environment, etc., and achieve the goal of weakening the environment Influence and promote the development of circular economy and the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

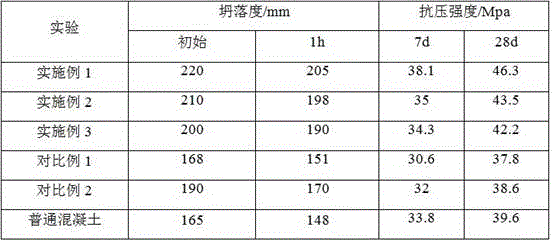

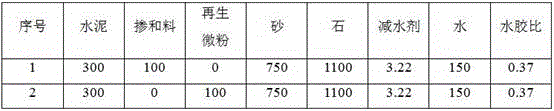

Examples

Embodiment 1

[0022] A method for regenerating micropowder activation, said activation method comprising the following steps:

[0023] 1) Crushing: crushing construction waste into 30mm particles;

[0024] 2) Pretreatment: calcining the obtained particles at 400°C for 3 hours;

[0025] 3) Ball milling: Ball mill the pretreated construction waste particles for 4 hours to obtain construction waste powder with a size of 30 μm to 80 μm;

[0026] 4) Calcination: place it at 600°C for 3 hours, heat up to 900°C for 1 hour, keep warm for 3 hours, and cool to room temperature for 1 hour to obtain regenerated micropowder;

[0027] 5) Mixing: The regenerated micropowder and its 1% by weight activator are fully mixed evenly, sealed and stored, and the activated regenerated micropowder can be obtained.

Embodiment 2

[0029] A method for regenerating micropowder activation, said activation method comprising the following steps:

[0030] 1) Crushing: crushing construction waste into 40mm particles;

[0031] 2) Pretreatment: calcining the obtained particles at 500°C for 4 hours;

[0032] 3) Ball milling: Ball mill the pretreated construction waste particles for 4 hours to obtain construction waste powder with a size of 30 μm to 80 μm;

[0033] 4) Calcination: place it at 600°C for 4 hours, heat up to 800°C for 1.5 hours, keep it warm for 3 hours, and cool to room temperature for 1.5 hours to obtain regenerated micropowder;

[0034] 5) Mixing: The regenerated micropowder and its 2% by weight activator are fully mixed evenly, sealed and stored, and the activated regenerated micropowder can be obtained.

Embodiment 3

[0036] A method for regenerating micropowder activation, said activation method comprising the following steps:

[0037] 1) Crushing: crushing construction waste into 25mm particles;

[0038] 2) Pretreatment: calcining the obtained particles at 300°C for 3 hours;

[0039] 3) Ball milling: mill the pretreated construction waste particles for 3 hours to obtain construction waste powder with a size of 30 μm to 80 μm;

[0040] 4) Calcination: place it at 700°C for 2h, heat up to 1000°C for 0.5h, keep warm for 1h, and cool to room temperature for 0.5h to obtain regenerated micropowder;

[0041] 5) Mixing: Fully mix the regenerated micropowder with 0.1% by weight of the activator, and store it in a sealed container to obtain the activated regenerated micropowder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com