Thermistor raw material and its preparation method and application

A technology of thermistors and raw materials, applied in the direction of resistors with negative temperature coefficients, etc., can solve the problems of inability to prepare thermistors, inconvenience, and limited temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

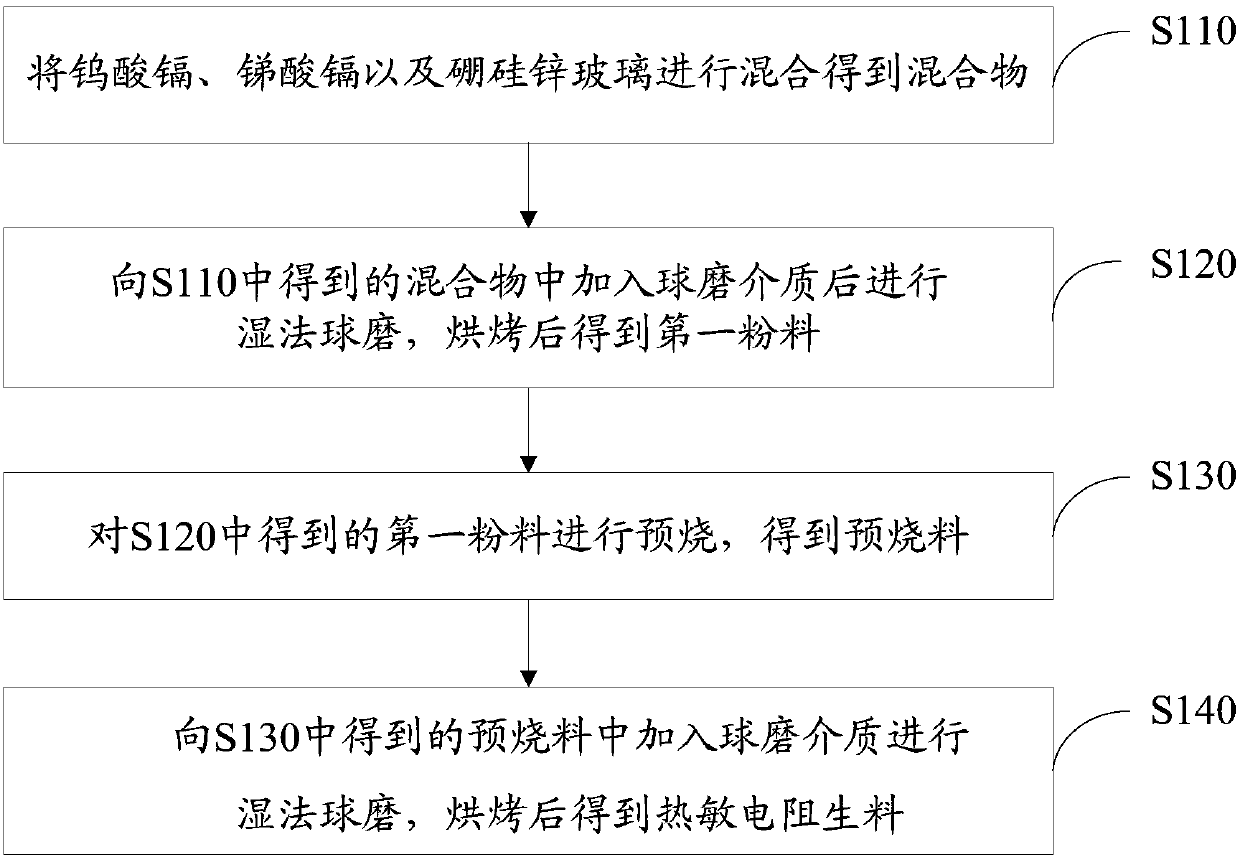

[0052] Such as figure 1 As shown, a method for preparing a thermistor raw material according to an embodiment includes the following steps S110-S140.

[0053] S110, mixing cadmium tungstate, cadmium antimonate and borosilicate zinc glass to obtain a mixture.

[0054] In the above mixture, by weight, cadmium tungstate accounts for 30-50 parts, cadmium antimonate accounts for 49-69 parts, and borosilicate-zinc glass accounts for 1-5 parts.

[0055] Among them, cadmium tungstate (CdWO 4 ) and cadmium antimonate (Cd 2 Sb 2 o 7 ), borosilicate zinc glass can be produced by domestic manufacturers.

[0056] In one embodiment, in the above mixture, by weight, cadmium tungstate accounts for 30 parts, cadmium antimonate accounts for 69 parts, and borosilicate zinc glass accounts for 1 part.

[0057] In another embodiment, in the above mixture, by weight, cadmium tungstate accounts for 50 parts, cadmium antimonate accounts for 49 parts, and borosilicate zinc glass accounts for 1 pa...

Embodiment 1

[0099] Weigh 30 parts of CdWO by weight 4 , 69 copies of Cd 2 Sb 2 o 7 and 1 part of borosilicate zinc glass to obtain a mixture. Take the mixture with a total weight of 250g and pour it into a polyurethane ball mill jar equipped with 600g of zirconium balls with a diameter of 3mm, add 250g of deionized water, seal it and wet mill it on a planetary ball mill for 4 hours at a speed of 400r / min. Pour the ground powder into a stainless steel pan, put it in an oven at 120°C and bake for 5 hours, pre-burn the dried powder in a muffle furnace at 900°C for 2 hours, and pour the pre-fired powder into a 600g container 1. In the polyurethane ball mill jar of zirconium balls with a diameter of 3 mm, add 250 g of deionized water, seal and wet mill for 4 hours on a planetary ball mill at a speed of 400 r / min. Pour the ground calcined material into a stainless steel pan, put it into an oven at 120°C and bake for 5 hours. Pass the dried powder through an 80-mesh sieve to obtain the NTC ...

Embodiment 2

[0101] Weigh 50 parts of CdWO by weight 4 , 49 copies of Cd 2 Sb 2 o 7 and 1 part of borosilicate zinc glass to obtain a mixture. Take the mixture with a total weight of 250g and pour it into a polyurethane ball mill jar equipped with 700g of zirconium balls with a diameter of 3mm, add 350g of deionized water, seal it and wet mill it on a planetary ball mill for 5 hours at a speed of 450r / min. Pour the ground powder into a stainless steel pan, put it in an oven at 130°C and bake for 4 hours, pre-burn the dried powder in a muffle furnace at 950°C for 1.5 hours, and then pour the pre-fired powder into a Add 350 g of deionized water to a polyurethane ball mill jar with 700 g of zirconium balls with a diameter of 3 mm, seal it, and wet grind it on a planetary ball mill for 5 hours at a speed of 450 r / min. Pour the ground calcined material into a stainless steel pan, put it into an oven at 130°C and bake for 4 hours. Pass the dried powder through an 80-mesh sieve to obtain the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com