A kind of preparation method of 2-nitro-5-bromopyridine

A bromopyridine and nitro technology, applied in the field of preparation of 2-nitro-5-bromopyridine, can solve the problems of harsh synthesis conditions, difficulty in synthesizing a large amount of compounds, and high synthesis cost, and achieve high product quality, cost reduction, and reduction of The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

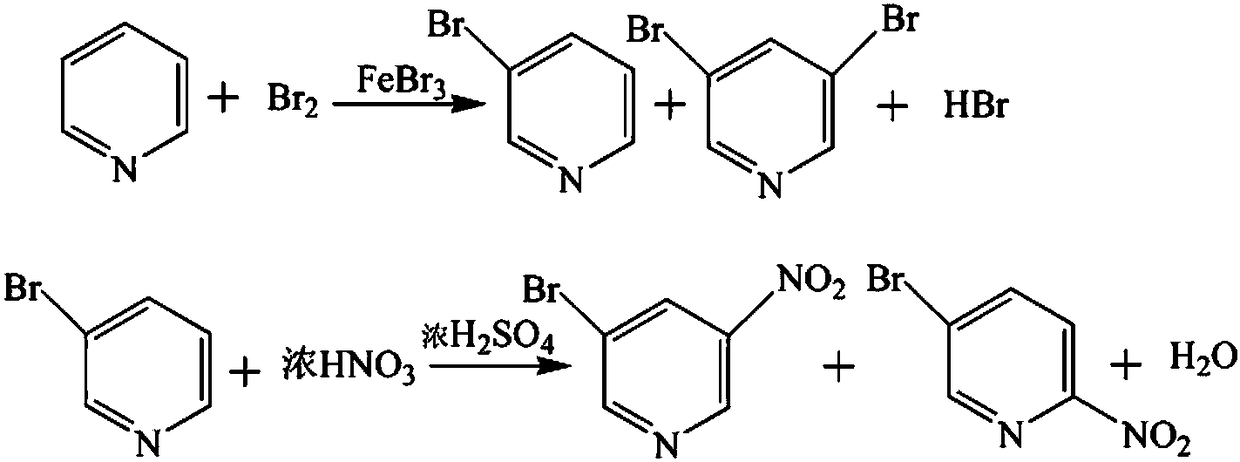

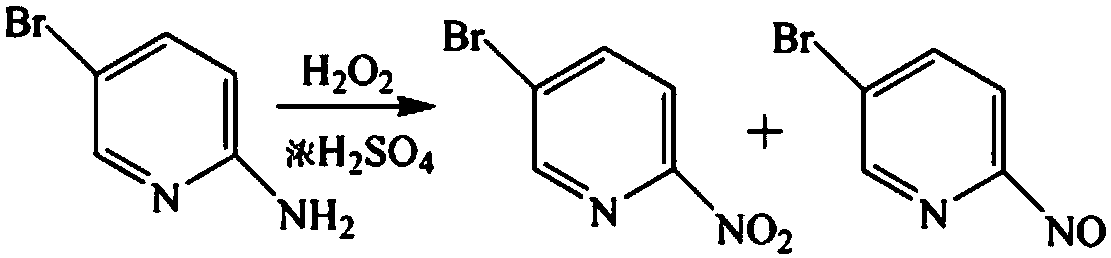

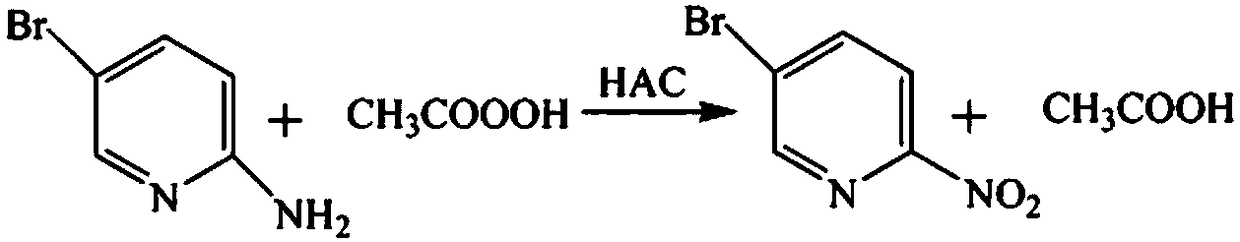

Method used

Image

Examples

Embodiment 1

[0040] Add 500L of glacial acetic acid into the 1000L reactor, start stirring and cooling the circulating water, when the temperature of the cooling circulating water drops to 20°C, slowly add 120kg of 2-amino-5-bromopyridine into the kettle in batches while stirring While adding, the temperature is controlled at 30°C. After the addition, stir for 30 minutes. In the above solution, slowly add 300kg of peracetic acid dropwise while stirring. When the dropwise addition reaches about 50kg, the temperature begins to rise slowly. Stop rising, and then add the remaining amount dropwise until the peracetic acid is added, and the temperature in the whole process is controlled at 40°C. After the dropwise addition was completed, the temperature was lowered to control the temperature at 30° C., and the reaction was performed at a constant temperature for 30 hours. After the reaction is complete, distill under reduced pressure. After about 600L of acetic acid is distilled off, the distill...

Embodiment 2

[0043]Add 500L of glacial acetic acid to the 1000L reactor, start stirring and cooling the circulating water, when the temperature of the cooling circulating water drops to 20°C, slowly add 100kg of 2-amino-5-bromopyridine to the kettle in batches while stirring While adding, the temperature is controlled at 25°C. After the addition, stir for 30 minutes. In the above solution, slowly add 280kg of peracetic acid dropwise while stirring. When the dropwise addition reaches about 50kg, the temperature begins to rise slowly. When it is not rising, when it starts to fall, add the remaining amount dropwise until the peracetic acid is added, and the temperature in the whole process is controlled at 35°C. After the dropwise addition was completed, the temperature was controlled at 35° C., and the reaction was performed at a constant temperature for 25 hours. After the reaction is complete, distill under reduced pressure. After about 550L of acetic acid is distilled off, the distillatio...

Embodiment 3

[0045] Add 500L of glacial acetic acid and 150L of acetic acid recovered in Example 1 to the 1000L reactor, turn on the circulating water and stir, after stirring evenly, slowly add 120kg of 2-amino-5-bromopyridine, the temperature is controlled at 20°C, and the addition is completed , stirred for 30 minutes, and slowly added 300kg of peracetic acid dropwise. When the dropwise addition reached about 50kg, the temperature began to rise slowly, and the dropwise addition was stopped. The temperature of the whole process was controlled at 30°C. After the dropwise addition was completed, the temperature was controlled at 40° C., and the reaction was performed at a constant temperature for 20 hours. After the reaction is complete, distill under reduced pressure. After about 600L of acetic acid is distilled off, the distillation is stopped. Cool the remaining feed liquid to 25°C, then add 500L of water, adjust the pH value of the feed liquid to 8 with 40% sodium hydroxide solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com