Method for synthesizing biological plastic precursor polyhydroxyalkanoate by utilizing lignin degrading bacterium

A technology of polyhydroxyalkanoate and lignin degrading bacteria is applied in the directions of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effect of reducing carbon source and its pretreatment cost, and simple fermentation conditions and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In an L-test tube, add 5 mL of LB medium, insert a single colony of the Cupriavidus basilensis B-8 strain, and cultivate and grow at 30° C. and 150 rpm until the optical density of the bacteria at 600 nm reaches 1.0. The pre-culture was centrifuged, washed, and then inoculated into Erlenmeyer flasks containing 100 mL of different concentrations of alkali lignin medium (1-6 g / L), and cultured with shaking at 30 °C and 150 rpm for 48 h. Among them, the medium preparation method: alkali lignin 1 ~ 6g, (NH 4 ) 2 SO 4 0.28g, K 2 HPO 4 1g, MgSO 4 0.2g, CaCl 2 0.1g, FeSO 4 0.05g, MnSO 4 0.02g, KH 2 PO 4 1g, agar 15g, distilled water 1000mL, pH 7.0~7.4.

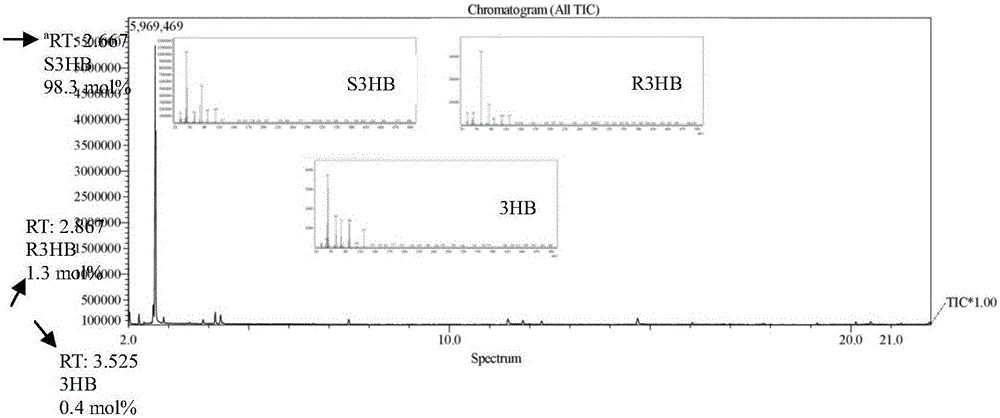

[0024] Collect 2 mL of sample, discard the supernatant, and resuspend the cells in 150 μL of deionized water and 50 μL of dimethyl sulfoxide. 5 μL of Nile Red (0.15 mg / mL) was added to the suspension for staining for 30 min. The results were then observed with a fluorescence microscope. figure 1 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com