A method for returning aerobic effluent to an anaerobic reactor for dilution and anaerobic ammonium oxidation for treating gas wastewater

An anaerobic reactor and anaerobic ammonium oxidation technology, which is applied in the field of anaerobic ammonium oxidation treatment of gas wastewater, can solve the problems of not being able to become the genus of opulent bacteria, nitrosating bacteria can not get the advantage, and the nitrosation reaction cannot be carried out. To achieve the effect of improving inhibition and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

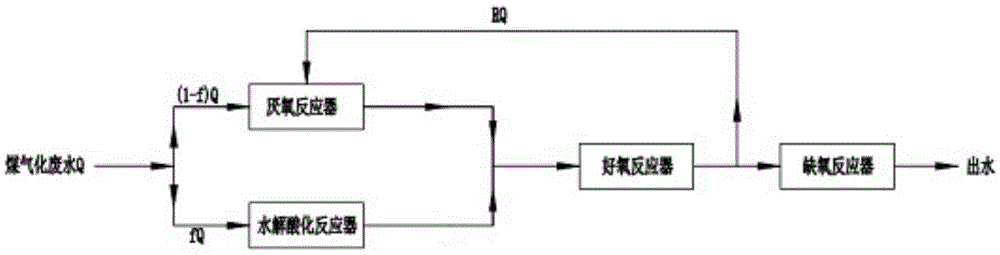

[0026]Embodiment 1: refer to figure 1 , the present invention is a kind of method that aerobic effluent returns to anaerobic reactor to dilute and treat gas waste water by anaerobic ammonium oxidation, the waste water that total water quantity is Q is divided into two parts, the waste water of fQ enters hydrolysis acidification reactor, and another part (1-fQ) The raw wastewater and part of the effluent RQ of the aerobic reactor enter the anaerobic reactor, and the effluents of the anaerobic reactor and the hydrolysis acidification reactor enter the aerobic reactor together, and then the effluent of the aerobic reactor into the anoxic reactor. The hydrolytic acidification reactor can achieve the purpose of improving the biodegradability of raw wastewater; the anaerobic reactor can not only remove organic matter, but also dilute the anaerobic influent concentration and reduce the concentration of raw wastewater through the reflux of the effluent from the aerobic reactor. Toxi...

Embodiment 2

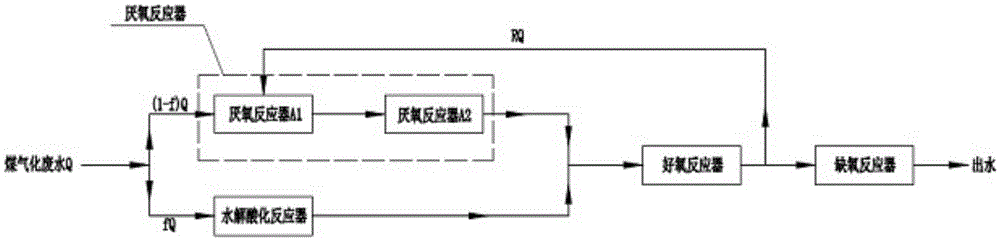

[0027] Embodiment 2, with reference to figure 2 , Embodiment 2 is substantially the same as Embodiment 1. The difference from Example 1 is that the anaerobic reactor is equipped with two stages, (1-fQ) raw wastewater and part of the effluent RQ of the aerobic reactor enter the first-stage anaerobic reactor A1, and the effluent of the anaerobic reactor A1 enters In the secondary anaerobic reactor A2, the reason for this setting is that the primary anaerobic reactor A1 mainly removes easily biodegradable organic matter, while achieving the effect of the anaerobic reactor in Example 1. The setting of the secondary anaerobic reactor A2 is mainly to further degrade the refractory organic matter that was not removed in the primary anaerobic reactor A1, so the purpose of setting the two-stage anaerobic reactor is to achieve the maximum degradation of organic matter and reduce the The toxicity of wastewater improves a stable environment for the operation of the aerobic section, and ...

Embodiment 3

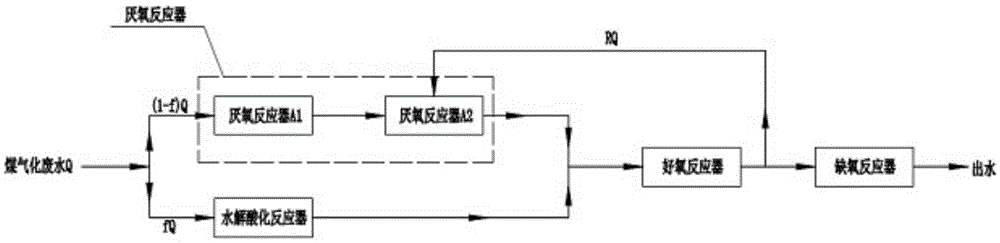

[0028] Embodiment 3: refer to image 3 , Embodiment 3 is substantially the same as Embodiment 2. The difference is that the effluent part of the aerobic reactor is returned to the anaerobic reactor A2, which can dilute the concentration and toxicity of the refractory organic matter in the primary anaerobic reactor A1 and enter the secondary anaerobic reactor A2, which is beneficial The metabolic work activity of anaerobic bacteria in the secondary anaerobic reactor A2 is increased, and at the same time, the purpose of anaerobic ammonium oxidation is realized, so that the function of the secondary anaerobic reactor A2 can be fully exerted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com