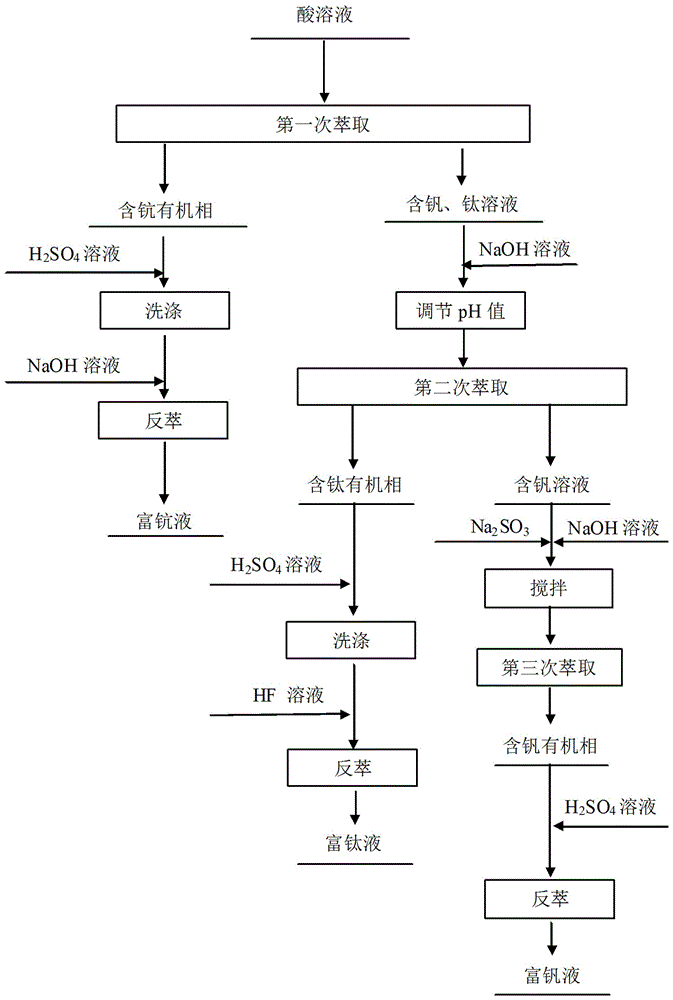

Technology for purifying scandium, titanium and vanadium from acid solution step by step

A technology of acid solution and sulfuric acid solution, which is applied in the direction of improving process efficiency, can solve the problems of difficult process operation, low concentration and enrichment multiples, and high impurity content, and achieve simple process operation, high concentration and enrichment multiples, and simplified The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Mix the acid solution and the extracted organic phase for the first extraction, and shake for 5-8 minutes under the conditions of O / A ratio of 1:8-10 and extraction temperature of 20-50°C. After the two phases are separated, continue to extract the organic phase Extract the new acid solution until the organic phase is saturated, and the scandium extraction rate is greater than 99%; the extracted organic phase is prepared from P507 extractant, TBP co-extractant and sulfonated kerosene, and the volume ratio of the three is 5-20: 5: 75~90; After the two phases are separated, the scandium-containing organic phase and the titanium and vanadium-containing solution are obtained. The scandium-containing organic phase is subjected to 0.3~0.5mol / L sulfuric acid solution at a ratio of O / A of 1:1~3, temperature Washing at 20~50°C for 1~3min; after washing, the scandium-containing organic phase is subjected to 2~5mol / L sodium hydroxide solution at a ratio of O / A of 8~10: 1 and a temp...

Embodiment 2

[0024] Mix the acid solution and the extracted organic phase for the first extraction, and shake for 5-8 minutes under the conditions of O / A ratio of 1:5-8 and extraction temperature of 20-50°C. After the two phases are separated, continue to extract the organic phase Extract the new acid solution until the organic phase is saturated, and the scandium extraction rate is greater than 99.5%; the extracted organic phase is prepared from P507 extractant, TBP co-extractant and sulfonated kerosene, and the volume ratio of the three is 5-20: 5: 75~90; After the two phases are separated, the scandium-containing organic phase and the titanium and vanadium-containing solution are obtained. The scandium-containing organic phase is subjected to 0.3~0.5mol / L sulfuric acid solution at a ratio of O / A of 1:1~3, temperature Washing at 20~50℃ for 1~3min; after washing, the scandium-containing organic phase is subjected to 2~5mol / L sodium hydroxide solution at a ratio of O / A of 5~8:1 and a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com