Air bag fabric and processing method thereof

A technology of airbags and fabrics, which is applied in textiles, fabrics, textiles and papermaking, etc., can solve problems such as error-prone, cumbersome preparation procedures, and complex components, so as to prevent errors, shorten processing procedures, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

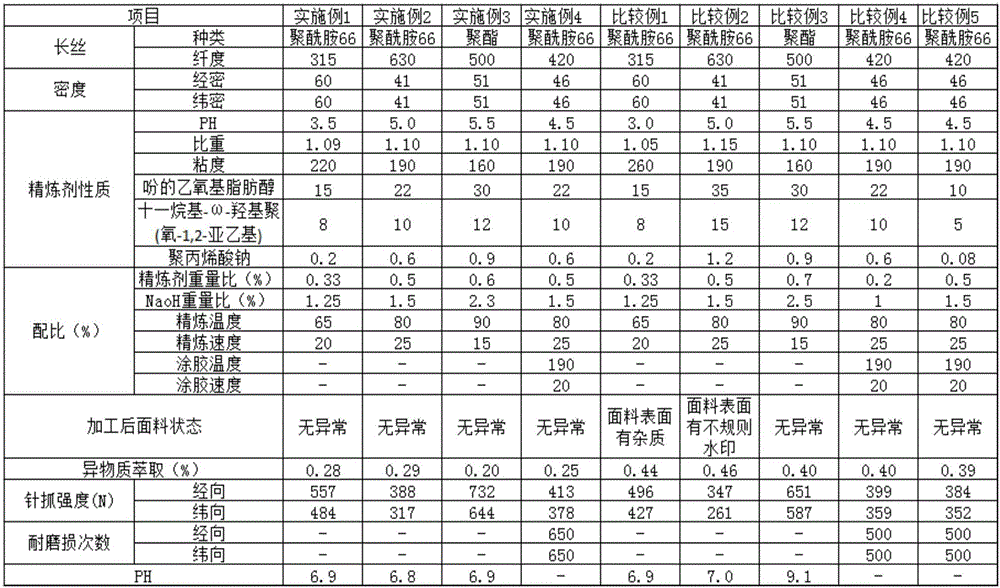

[0026] Polyamide 66 filaments with a fineness of 315D are used to weave plain fabrics with a density of 60 threads / inch. The pH of the new refining agent used is 3.5 and the specific gravity is 1.09g / cm 3 , the viscosity is 220mPa·s, the ethoxylated fatty alcohol content of its components phenene is 15%, the content of undecyl-undecahydroxy poly(oxygen-1,2-ethylene) is 8%, and the content of sodium polyacrylate is 0.2%. . In the refining process, the weight ratio of refining agent is 0.33%, the weight ratio of NaOH (concentration 32%) is 1.25%, the refining temperature is 65° C., and the refining speed is 20 m / min. Finally, the airbag fabric of the present invention is obtained, and the airbag fabric is measured. The foreign matter extraction result of the fabric was 0.28%, the needle grip strength was 557N in the warp direction, and 484N in the weft direction. The pH is 6.9. The results of its physical properties are shown in Table 1.

Embodiment 2

[0028] Polyamide 66 filaments with a fineness of 630D are used to weave plain fabrics with a density of 41 threads / inch. The pH of the new refining agent used is 5.0 and the specific gravity is 1.10g / cm 3 , the viscosity is 190mPa·s, the ethoxy fatty alcohol content of its components is 22%, the content of undecyl-undecahydroxy poly(oxygen-1,2-ethylene) is 10%, and the content of sodium polyacrylate is 0.6%. In the refining process, the weight ratio of refining agent is 0.5%, the weight ratio of NaOH (concentration 32%) is 1.5%, the refining temperature is 80°C, and the refining speed is 25m / min. Finally, the airbag fabric of the present invention is obtained, and the airbag fabric is measured. The foreign matter extraction result of the fabric was 0.29%, the needle grip strength was 388N in the warp direction, and 317N in the weft direction. The pH is 6.8. The results of its physical properties are shown in Table 1.

Embodiment 3

[0030] Polyester filaments with a denier of 500D are used to weave plain fabrics with a density of 51 threads / inch. The pH of the new refining agent used is 5.5, and the specific gravity is 1.10g / cm 3 , the viscosity is 160mPa·s, the ethoxylated fatty alcohol content of its components is 30%, the content of undecyl-undecahydroxy poly(oxygen-1,2-ethylene) is 12%, and the content of sodium polyacrylate is 0.9%. In the refining process, the weight ratio of refining agent is 0.6%, the weight ratio of NaOH (concentration 32%) is 2.3%, the refining temperature is 90°C, and the refining speed is 15m / min. Finally, the airbag fabric of the present invention is obtained, and the airbag fabric is measured. The foreign matter extraction result of the fabric was 0.20%, the needle grip strength was 732N in the warp direction, and 644N in the weft direction. The pH is 6.9. The results of its physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com