Construction method of large-span overhead steel-structure truss

A technology of steel structure and steel truss, applied in the field of construction method of large-span aerial steel structure truss, can solve the problems of heavy hoisting weight, inconvenient construction, large hoisting radius, etc., so as to improve work efficiency, save construction cost, and speed up construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

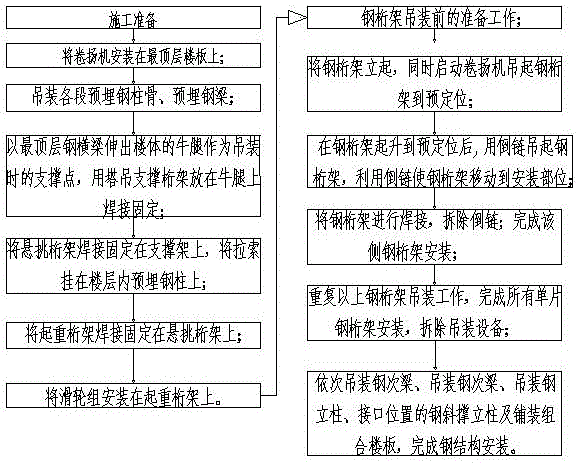

[0043] A construction method of a large-span aerial steel structure truss in this embodiment, such as figure 1 As shown, it is mainly realized through the following technical solutions, including the following steps:

[0044] Step 1: Preparatory work before construction;

[0045] Step 2: Hoist the pre-embedded steel columns and pre-embedded steel beams of each section;

[0046] Step 3: Installation of hoisting equipment:

[0047] Step 31: Install the two winches on the topmost floors of the two main buildings;

[0048] Step 32: Use the corbels of the topmost steel beam protruding from the building as the support point during hoisting, and place the supporting truss on the corbels for welding and fixing;

[0049] Step 33: Weld and fix the cantilever truss on the supporting frame, and hang the cable on the embedded steel column in the floor;

[0050] Step 34: Weld and fix the lifting truss on the cantilever truss;

[0051] Step 35: Fix the pulley block on the lifting truss;...

Embodiment 2

[0061]This embodiment is further optimized on the basis of the above embodiments. Further, a construction method of a large-span aerial steel structure truss, the first step specifically includes the following steps:

[0062] Step 11: Transport the small structural parts manufactured in sections to the assembly platform on the construction site, conduct inspection and acceptance according to the specification requirements, and assemble the small structural parts into a single-piece truss after passing the test; the assembly platform is set in the middle of the floor where the steel truss needs to be installed On the floor; the assembled platform is installed on the platform pier on the main beam; the platform pier is arranged on the main beam every 3 to 5 meters; the upper surface of the platform pier is on the same horizontal elevation;

[0063] Step 12: Transport the assembled single-piece steel truss to the bottom of the lifting point through the sliding track, and the slidi...

Embodiment 3

[0068] This embodiment is further optimized on the basis of the above embodiments. Further, a construction method of a large-span aerial steel structure truss includes the following steps:

[0069] Step 1: Preparatory work before construction;

[0070] Step 11: Transport the small structural parts manufactured in sections to the assembly platform on the construction site, conduct inspection and acceptance according to the specification requirements, and assemble the small structural parts into a single-piece truss after passing the test; the assembly platform is set in the middle of the floor where the steel truss needs to be installed On the floor; the assembled platform is installed on the platform pier on the main beam; the platform pier is arranged on the main beam every 3-5 meters; the upper surface of the platform pier is on the same level;

[0071] Step 12: Transport the assembled single-piece steel truss to the bottom of the lifting point through the sliding track, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com