Denoising and tail gas removing isolation room for automotive drum tests

A drum test and isolation room technology, applied in industrial buildings, building components, walls, etc., can solve problems such as exhaust pollution and noise pollution, and achieve the effects of reducing hazards, reducing noise pollution, and excellent sound-absorbing and sound-insulating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

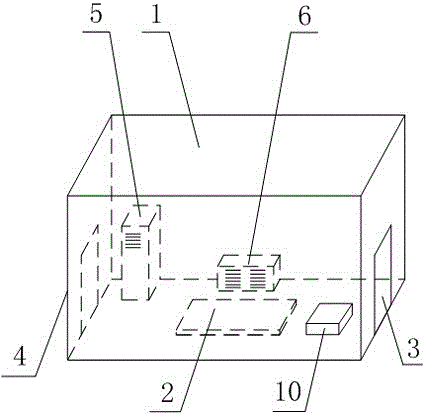

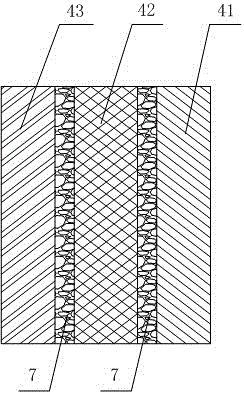

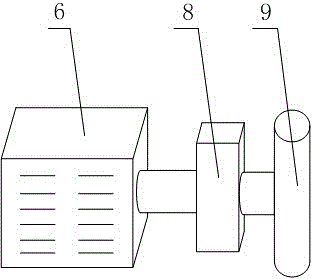

[0021] Such as Figure 1 to Figure 3 A noise-reducing and exhaust-gas-removing isolation chamber for automobile drum tests shown, wherein figure 1 The dotted line in the center indicates the inner part of the working chamber 1, wherein the filter device 8 and the three-way catalytic converter 9 are connected to the rear of the centrifugal fan 6 and are not in the figure 1 marked in . It includes a studio 1 with a drum test bench 2 inside, and the studio 1 includes two automatic doors 3 facing each other; the wall of the studio 1 is a sound insulation wall 4, and the sound insulation wall 4 includes Perlite sound-absorbing board 41, vacuum glass layer 42, and cement wood chip sound-absorbing board 43 are arranged in sequence; glass wool 7 is filled between the perlite sound-absorbing board 41 and vacuum glass layer 42, and the vacuum glass layer 42 and cement wood chip Glass wool 7 is filled between the sound-absorbing panels 43; a temperature adjustment device 5, a centrifug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com