Preparation method of carbon fiber cotton capable of absorbing sound, preventing cold and preserving heat

A technology of carbon fiber and thermal insulation cotton, which is applied in the direction of chemical instruments and methods, coatings, non-woven fabrics, etc., can solve the problems of high density of sound insulation and heat insulation materials, secondary injuries of personnel, and increased weight of the car compartment, and achieve good sound insulation and sound absorption performance , Good heat insulation and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

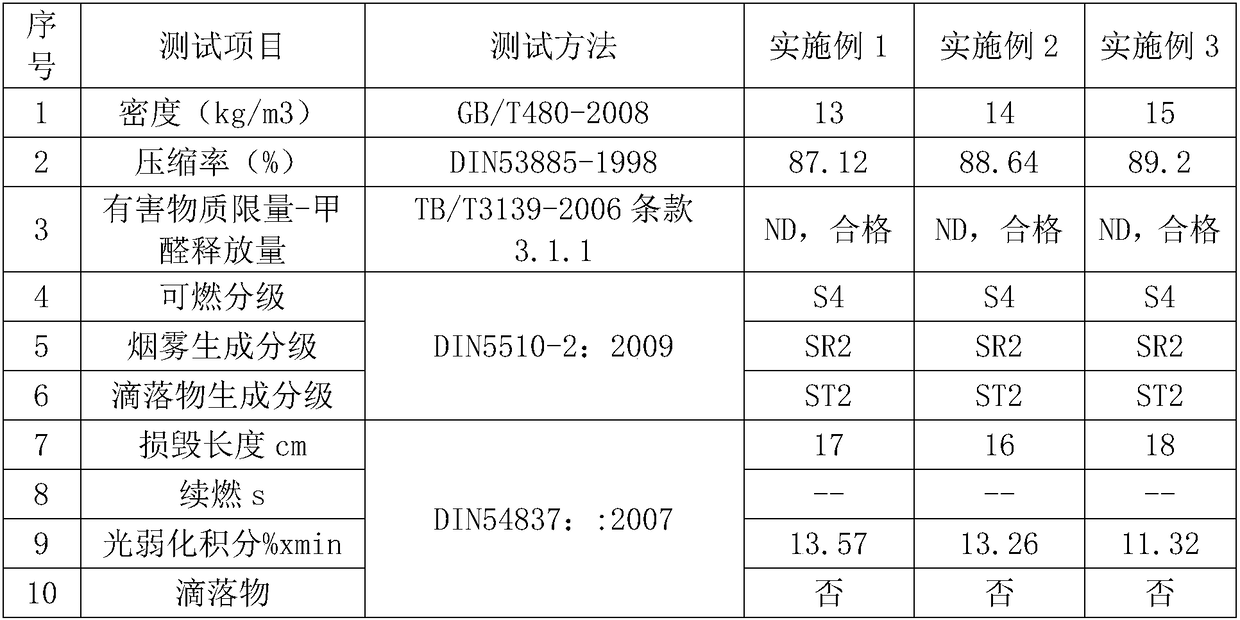

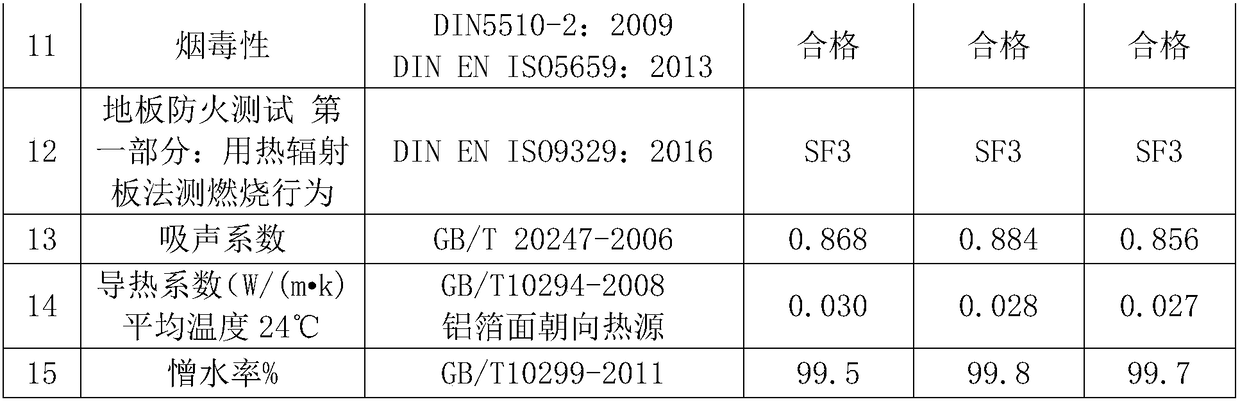

Embodiment 1

[0023] The preparation method of a kind of carbon fiber sound-absorbing cold-proof insulation cotton of the present embodiment comprises the following steps:

[0024] Step 1) Treating the surface of the polyacrylonitrile carbon fiber with a waterproof coating to prepare a carbon fiber with an oxygen index of 45%;

[0025] Step 2) In terms of mass percentage, the carbon fiber is 90%, and the low-melting-point polyester fiber is 10%. The carbon fiber and the low-melting-point polyester fiber are subjected to heat treatment after carding, and the heat treatment temperature is 50°C. The prepared density is 13kg / m 3 carbon fiber composite material layer;

[0026] Step 3) After the carbon fiber composite material layer is cooled, the anti-radiation film layer formed by compounding the aluminum foil reflective film with adhesive backing is obtained to obtain the carbon fiber sound-absorbing cold-proof and thermal insulation cotton.

[0027] Among them, the melting point of the low ...

Embodiment 2

[0030] The preparation method of a kind of carbon fiber sound-absorbing cold-proof insulation cotton of the present embodiment comprises the following steps:

[0031] Step 1) Treating the surface of the polyacrylonitrile carbon fiber with a waterproof coating to prepare a carbon fiber with an oxygen index of 50%;

[0032] Step 2) In terms of mass percentage, the carbon fiber is 50%, and the low-melting-point polyester fiber is 50%, and the carbon fiber and the low-melting-point polyester fiber are subjected to heat treatment after carding. The prepared density is 14kg / m 3 carbon fiber composite material layer;

[0033] Step 3) After the carbon fiber composite material layer is cooled, the anti-radiation film layer formed by compounding the aluminum foil reflective film with adhesive backing is obtained to obtain the carbon fiber sound-absorbing cold-proof and thermal insulation cotton.

[0034] Among them, the melting point of the low melting point polyester fiber is 103°C. ...

Embodiment 3

[0037] The preparation method of a kind of carbon fiber sound-absorbing cold-proof insulation cotton of the present embodiment comprises the following steps:

[0038] Step 1) Treating the surface of the polyacrylonitrile carbon fiber with a waterproof coating to prepare a carbon fiber with an oxygen index of 55%;

[0039] Step 2) In terms of mass percentage, the carbon fiber is 80%, and the low-melting point polyester fiber is 20%, and the carbon fiber and the low-melting point polyester fiber are subjected to heat treatment after carding. The prepared density is 15kg / m 3 carbon fiber composite material layer;

[0040] Step 3) After the carbon fiber composite material layer is cooled, the anti-radiation film layer formed by compounding the aluminum foil reflective film with adhesive backing is obtained to obtain the carbon fiber sound-absorbing cold-proof and thermal insulation cotton.

[0041] Among them, the melting point of the low melting point polyester fiber is 106°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com