Flexible foam-filled honeycomb constrained damping sandwich structure and preparation method thereof

A technology of foam filling and honeycomb restraint, which is applied in the field of composite materials, can solve the problems of increasing dangerous accidents, reducing the attention of pilots, and failing to meet the needs of noise reduction, so as to improve the sound insulation and shock absorption performance, the preparation method is simple and feasible, sound insulation and sound absorption good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

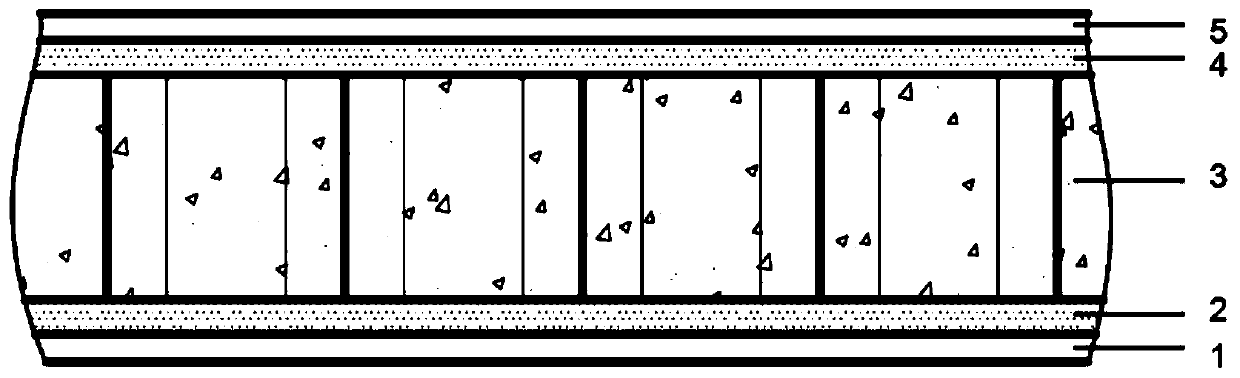

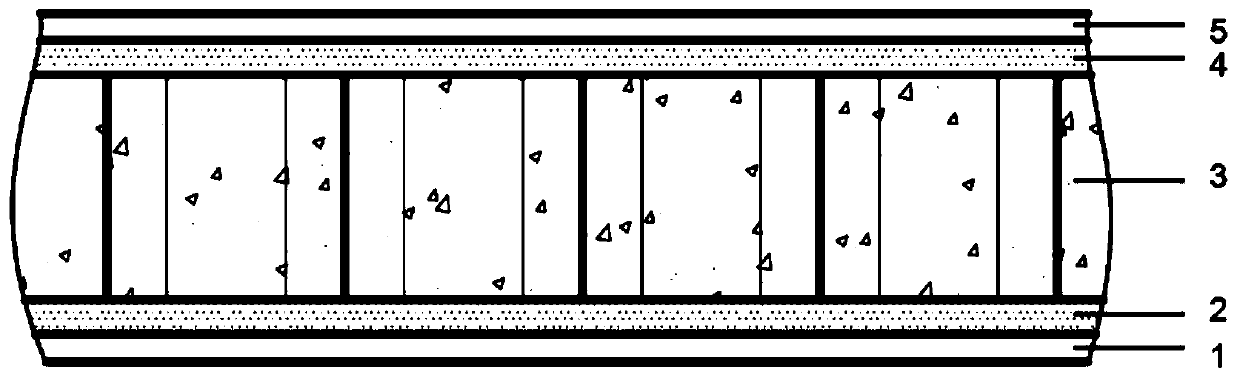

[0021] A flexible foam-filled honeycomb constrained damping sandwich structure: from bottom to top, it includes a constrained damping layer 1, a sound-insulating layer 2, a sound-absorbing layer 3, a sound-insulating layer 4, and a constrained damping layer 5, wherein the constrained damping layer 1, constrained damping layer 5 is the damping rubber of the bonding film material, the sound-insulating layer 2 and the sound-insulating layer 4 are hard fiberboards, and the sound-absorbing layer 3 is a flexible foam-filled honeycomb; the flexible foam in the sound-absorbing layer 3 is melamine foam with a thickness of 6mm , the density is 7.5kg / m 3 , the noise reduction coefficient NRC is 0.90, and the porosity is 98.5%. The honeycomb in the sound-absorbing layer 3 is an aramid honeycomb with a thickness of 6 mm; The two layers of the layer are the same material with different thicknesses, and the same material with the same thickness is not used to avoid the same matching frequenc...

Embodiment 2

[0034]

[0035] A flexible foam-filled honeycomb constrained damping sandwich structure: from bottom to top, it includes a constrained damping layer 1, a sound-insulating layer 2, a sound-absorbing layer 3, a sound-insulating layer 4, and a constrained damping layer 5, wherein the constrained damping layer 1, constrained damping layer 5 is the damping rubber of the adhesive film material, the sound-insulating layer 2 and the sound-insulating layer 4 are hard fiberboards, and the sound-absorbing layer 3 is a flexible foam-filled honeycomb; the flexible foam in the sound-absorbing layer 3 is 8 mm thick melamine foam , the density is 8.0kg / m 3 , the noise reduction coefficient NRC is 0.95, and the porosity is 99.3%. The honeycomb in the sound-absorbing layer 3 is an 8mm thick aramid honeycomb; The two layers of the layer are the same material with different thicknesses, and the same material with the same thickness is not used to avoid the same matching frequency in the two la...

Embodiment 3

[0042] A flexible foam-filled honeycomb constrained damping sandwich structure: from bottom to top, it includes a constrained damping layer 1, a sound-insulating layer 2, a sound-absorbing layer 3, a sound-insulating layer 4, and a constrained damping layer 5, wherein the constrained damping layer 1, constrained damping layer 5 is the damping rubber of the bonding film material, the sound-insulating layer 2 and the sound-insulating layer 4 are hard fiberboards, and the sound-absorbing layer 3 is a flexible foam-filled honeycomb; the flexible foam in the sound-absorbing layer 3 is 10 mm thick melamine foam , the density is 8.5kg / m 3 , the noise reduction coefficient NRC is 0.85, and the porosity is 95.8%. The honeycomb in the sound-absorbing layer 3 is an aramid honeycomb with a thickness of 10 mm; The two layers of the layer are the same material of different thickness, do not use the same material of the same thickness, avoid the same matching frequency in the two layers, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com