Multistage thermo-acoustic generator set and multistage heat regenerative refrigeration system provide with same

A technology for generator sets and thermoacoustic engines, which is applied in refrigerators, engine components, refrigeration and liquefaction, etc., can solve the problems of low efficiency, large loss of resonance tubes, and increased scavenging volume, so as to improve the working efficiency of the system and improve the thermoelectric efficiency. , the effect of high thermoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Such as image 3 As shown, the multi-stage thermoacoustic generator set provided by this embodiment includes multiple sets of thermoacoustic engines, and multiple sets of thermoacoustic engines are connected in series between the compressor and the generator, and each set of thermoacoustic engines is connected by a harmonic oscillator Component coupling, resonant sub-components are used to form traveling wave sound fields in each group of thermoacoustic engines at the same time, using resonant sub-components to achieve good matching between adjacent two groups of thermoacoustic engine groups, in each group of thermoacoustic engine groups The internal energy can form a traveling wave sound field at the same time, thereby improving the thermoelectric efficiency of the thermoacoustic generator set. Cascade utilization of thermal energy.

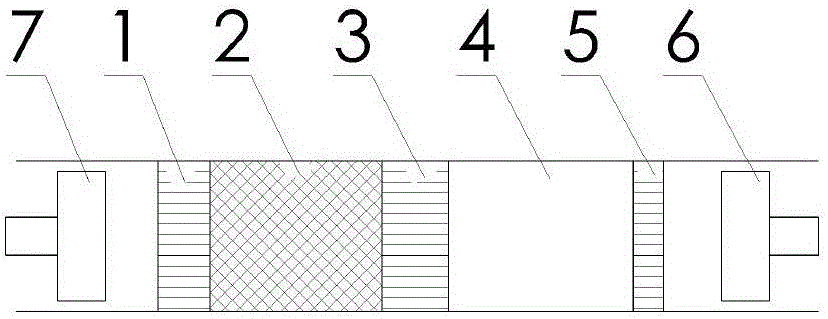

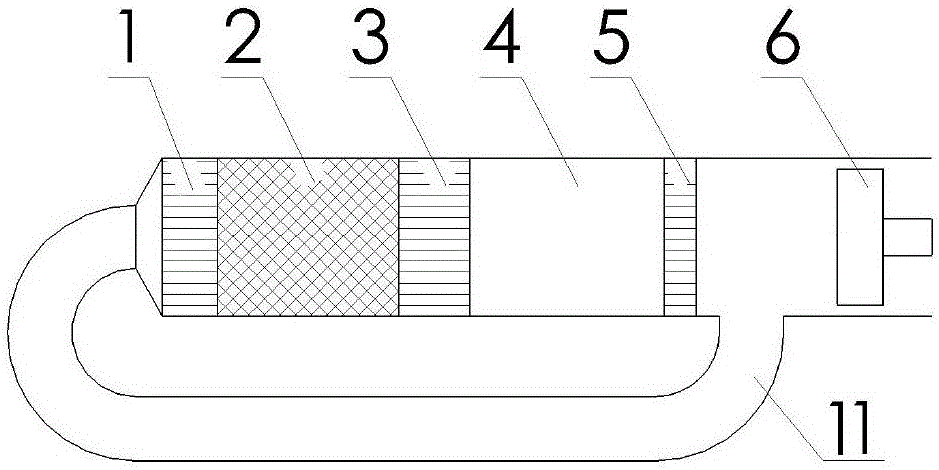

[0035] The thermoacoustic engine includes a main water cooler 1, a regenerator 2, a heater 3, a thermal buffer pipe 4 and a secondary w...

Embodiment 2

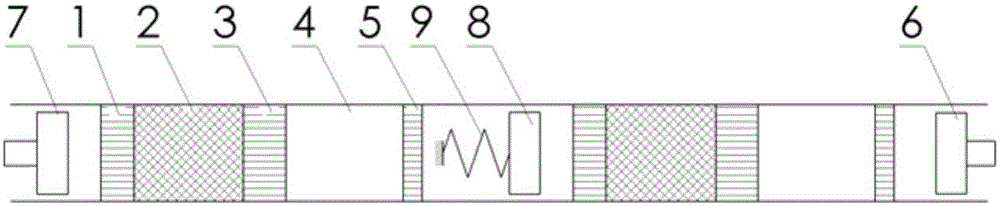

[0045] The multi-stage thermoacoustic generator set of the second embodiment is basically the same as the multi-stage thermoacoustic generator set described in the first embodiment, and the similarities will not be repeated. The difference lies in: the multi-stage thermoacoustic generator set of the second embodiment Among them, there are three sets of thermoacoustic engines installed in sequence between the compressor and the generator, and each two sets of thermoacoustic engines are coupled through the resonant sub-assembly. When the resonant sub-assembly is installed, the resonant spring 9 and the mass piston 8 connected, the mass piston 8 can reciprocate toward the sound wave inlet direction of the thermoacoustic engine.

[0046] On the basis of Embodiment 1, the multi-stage thermoacoustic generating set of Embodiment 2 increases the number of thermoacoustic engines to three, such as Figure 4 As shown, therefore, the thermoelectric efficiency of this multi-stage thermoaco...

Embodiment 3

[0049] Such as Figure 5 As shown, the multi-stage thermoacoustic engine unit of the third embodiment is basically the same as the multi-stage thermoacoustic engine unit described in the first embodiment, and the similarities will not be repeated. The difference lies in: the resonator assembly of the third embodiment During installation, a bypass groove is provided between the mechanical energy outlet and the sound wave inlet of two adjacent groups of thermoacoustic engines, and the mass piston 8 is installed in the bypass groove through a resonant spring 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com