Automobile exhaust pipe and noise-reducing coating material for exhaust pipe

A technology for automobile exhaust and exhaust pipes, which is applied in the field of mechanical parts manufacturing, can solve problems such as high noise and easy freezing, and achieve the effects of long service life, reduced noise and good noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

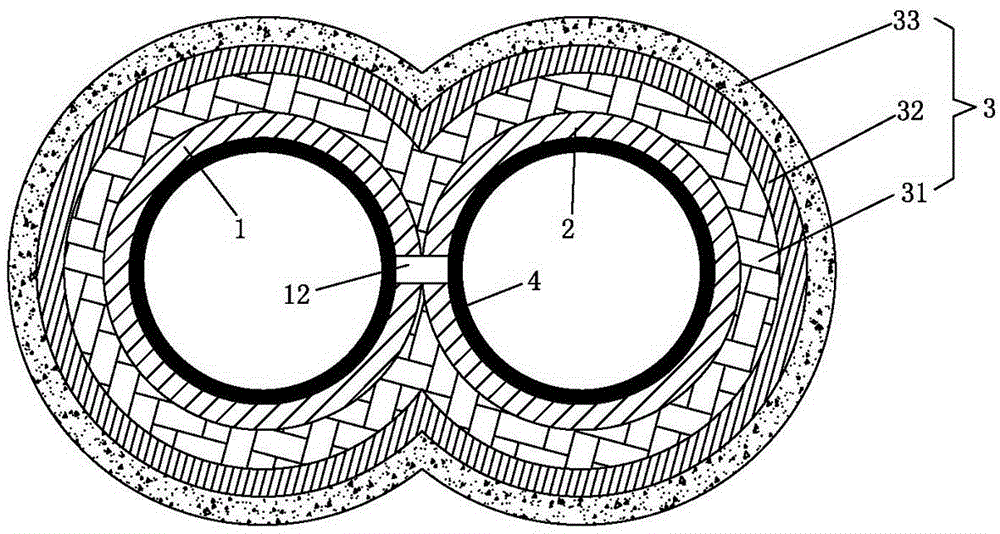

[0017] Embodiment one: refer to figure 1 , an automobile exhaust pipe and a sound-absorbing coating for the exhaust pipe, comprising a left exhaust pipe main body 1 and a right exhaust pipe main body 2, and the left exhaust pipe main body 1 and the right exhaust pipe main body 2 are provided with mutual Connected through hole 12. The inner walls of the left and right exhaust pipe main bodies 1 and 2 are provided with a sound-absorbing paint layer 4, the sound-absorbing paint layer 4 is composed of the following components by weight: 8-15 parts of high temperature resistant resin, 4-6 parts of amino resin, 3-9 parts of organic solvent, 1-5 parts of glass fiber, 2-parts of silicon carbide, 3-7 parts of surface modifier, 1-4 parts of corrosion inhibitor, 4-9 parts of dipropylene glycol butyl ether, 2 parts of amine compounds -5 parts, 5-10 parts of nano-organic montmorillonite, 3-8 parts of stannous decanoate, 3-9 parts of nano-calcium sulfate, and 1-3 parts of plasticizer. The...

Embodiment 2

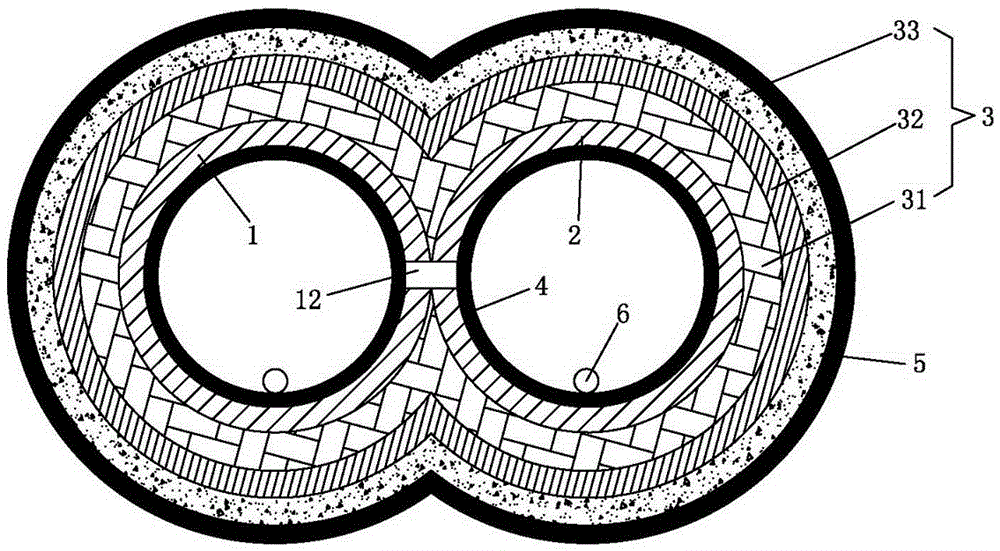

[0018] Embodiment two: refer to figure 2 , an automobile exhaust pipe and a sound-absorbing coating for the exhaust pipe, comprising a left exhaust pipe main body 1 and a right exhaust pipe main body 2, and the left exhaust pipe main body 1 and the right exhaust pipe main body 2 are provided with mutual Connected through hole 12. The inner walls of the left and right exhaust pipe main bodies 1 and 2 are provided with a sound-absorbing paint layer 4, the sound-absorbing paint layer 4 is composed of the following components by weight: 8-15 parts of high temperature resistant resin, 4-6 parts of amino resin, 3-9 parts of organic solvent, 1-5 parts of glass fiber, 2-parts of silicon carbide, 3-7 parts of surface modifier, 1-4 parts of corrosion inhibitor, 4-9 parts of dipropylene glycol butyl ether, 2 parts of amine compounds -5 parts, 5-10 parts of nano-organic montmorillonite, 3-8 parts of stannous decanoate, 3-9 parts of nano-calcium sulfate, and 1-3 parts of plasticizer. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com