A Multi-stage Wastewater Recycling Hot Water Supply System

A waste water recovery and hot water supply technology, applied in water heaters, heat exchangers, indirect heat exchangers, etc. Problems such as rising water temperature, to achieve the effect of solving insufficient hot water pressure, facilitating popularization and application, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

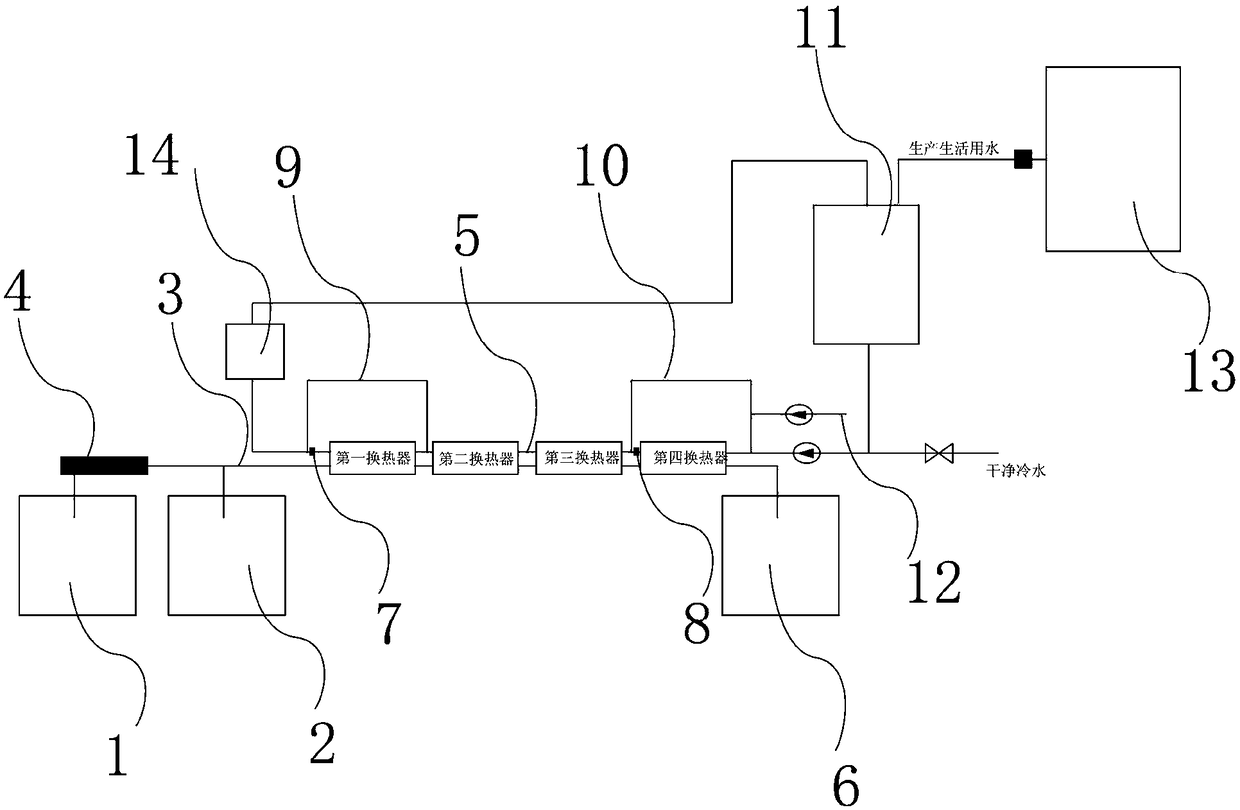

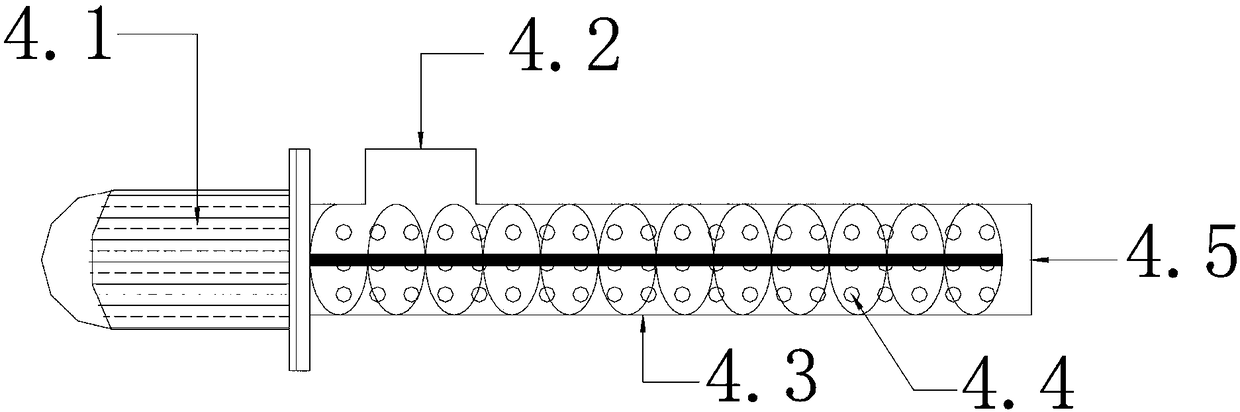

[0022] like figure 1 , is a schematic diagram of the overall structure of the present invention, including a sewage pool 2, the sewage pool 2 is connected with a sewage pipe 3, and the sewage pipe 3 is provided with a slag discharger 4, and the slag discharger 4 includes a housing 4.3, and the housing 4.3 is provided with The sewage inlet 4.2 and the sewage hole 4.4, the sewage enters the housing 4.3 through the sewage inlet 4.2, and the sundries are discharged through the rotating mechanism (driven by the motor 4.1) in the housing 4.3, while the sewage continues to flow in the sewage pipe through the sewage hole 4.4 3 flow, including the first heat exchanger, the second heat exchanger, the third heat exchanger and the fourth heat exchanger in the system, which are arranged in order from left to right. In the above heat exchangers, the sewage pipe 3 Connect with the above-mentioned heat exchanger in turn from left to right; on the right side, there is a cold water pipeline 5, ...

Embodiment 2

[0029] The difference from Embodiment 1 is that the first heat exchanger is provided with a water supply pipeline, and the rest of the working methods and principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com