Multisource fluid waste heat recycling system

A waste heat recovery and thermal system technology, applied in the direction of fluid heaters, heat pumps, heat storage equipment, etc., can solve the problems of insufficient waste heat storage, unable to meet the waste heat utilization of workshops, unable to recover various heat sources of different properties, and unable to fully store waste heat, etc. , to achieve the effect of reducing cleaning and maintenance times, ensuring recycling and utilization, and ensuring full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

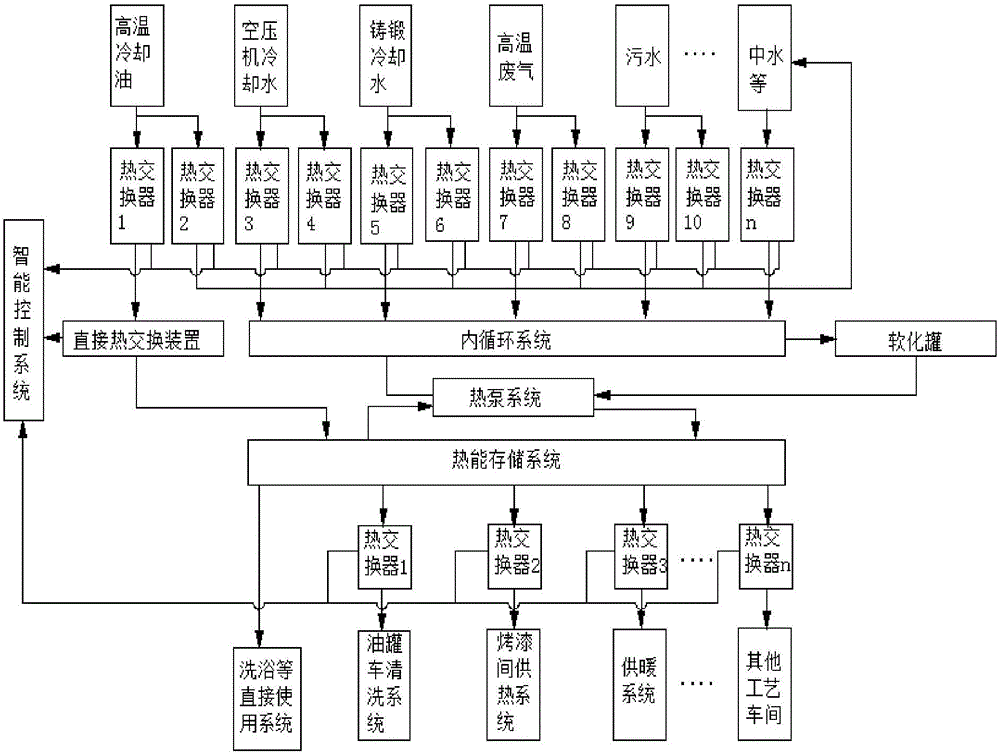

[0030] A multi-source waste heat recovery system such as figure 1As shown, from the perspective of the system, it is divided into heat source system, multi-heat source and heat exchange system of heat source internal circulation system of heat pump, softening tank water treatment system, high-efficiency heat exchange and heat pump system, heat storage hot water system, multi-purpose heat Exchange system and hot water delivery system, etc. Each system unit is a separate internal cycle, and the water in each unit does not touch each other, and the heat is directly transferred to another cycle through heat exchange. High-temperature flue gas and high-temperature cooling oil pass through heat exchangers and direct heat exchange devices to obtain higher-temperature water directly transfer heat to the water tank of the thermal energy storage system or use other cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com