Optical waveguide plate and optical fiber coupling connection method, optical waveguide plate and communication transmission system

An optical fiber coupling and connection method technology, which is applied to the optical waveguide light guide, the coupling of the optical waveguide, the light guide, etc., can solve the problems of poor alignment between the optical waveguide plate and the fiber, poor transmission stability, etc. Accuracy and the effect of improving core competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

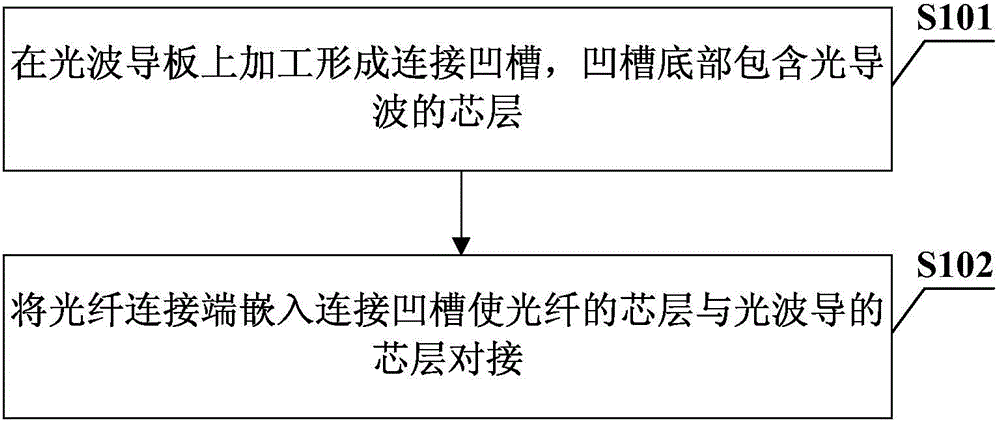

[0040] The optical waveguide plate and the optical fiber coupling connection method of this embodiment, such as figure 1 shown, including the following steps:

[0041] Step S101: Processing and forming a connecting groove on the optical waveguide plate, the bottom of the groove contains the core layer of the optical waveguide;

[0042] In this step, the optical waveguide board refers to a printed circuit board with an optical waveguide transmission layer, and it should be understood that various existing circuit boards containing an optical waveguide transmission layer are included. Process the existing optical waveguide plate, that is, process the core layer and the surrounding core layer of the optical waveguide plate to form a connection groove. The core layer of the optical fiber and the core layer of the optical waveguide are butted during the groove. Further, in order to facilitate the accuracy of butt joint between the core layer of the optical fiber and the core laye...

Embodiment 2

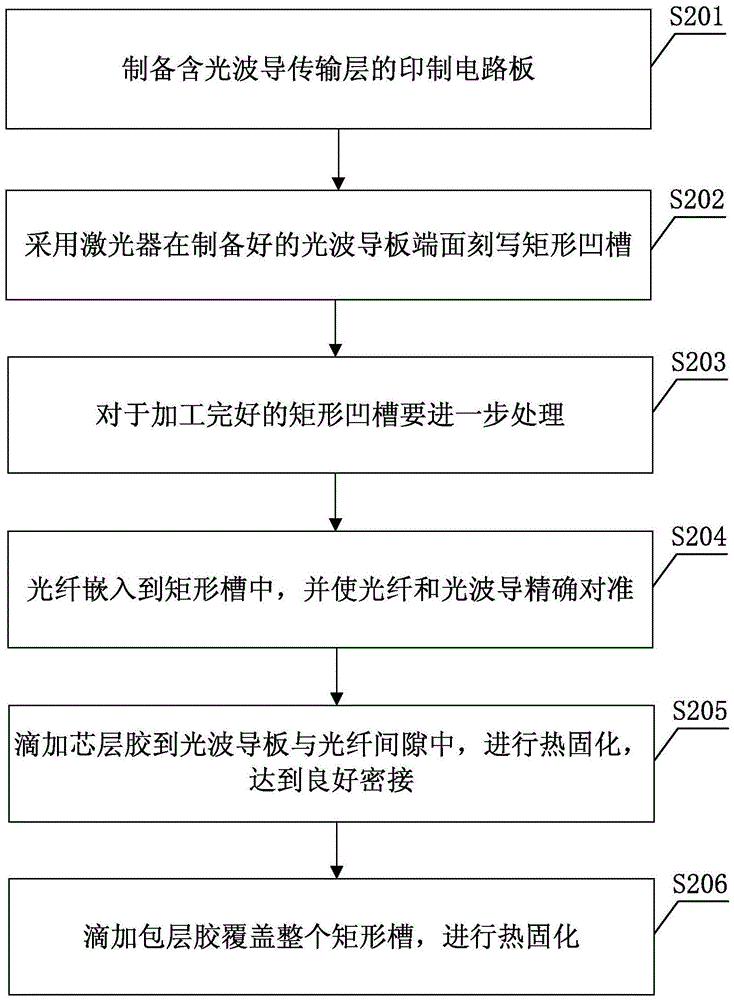

[0052] The coupling connection method between the optical waveguide plate and the optical fiber of the present embodiment of the present embodiment, the method in this example is specifically as follows figure 2 shown, including the following steps:

[0053] Step S201: preparing a printed circuit board containing an optical waveguide transmission layer, that is, an optical waveguide plate;

[0054] In this step, the prepared optical waveguide plate in this step has a core layer size of 50 μm x 50 μm, and an upper cladding layer and a lower cladding layer thickness of 50 μm, or the core layer, upper cladding layer, and lower cladding layer size of the optical waveguide are not limited to above dimensions.

[0055] Step S202: Using a laser to write a rectangular groove on the end surface of the prepared optical waveguide plate;

[0056] In this step, specific parameters such as exposure energy, dot frequency, and stepping speed can be set on the working software of the laser,...

Embodiment 3

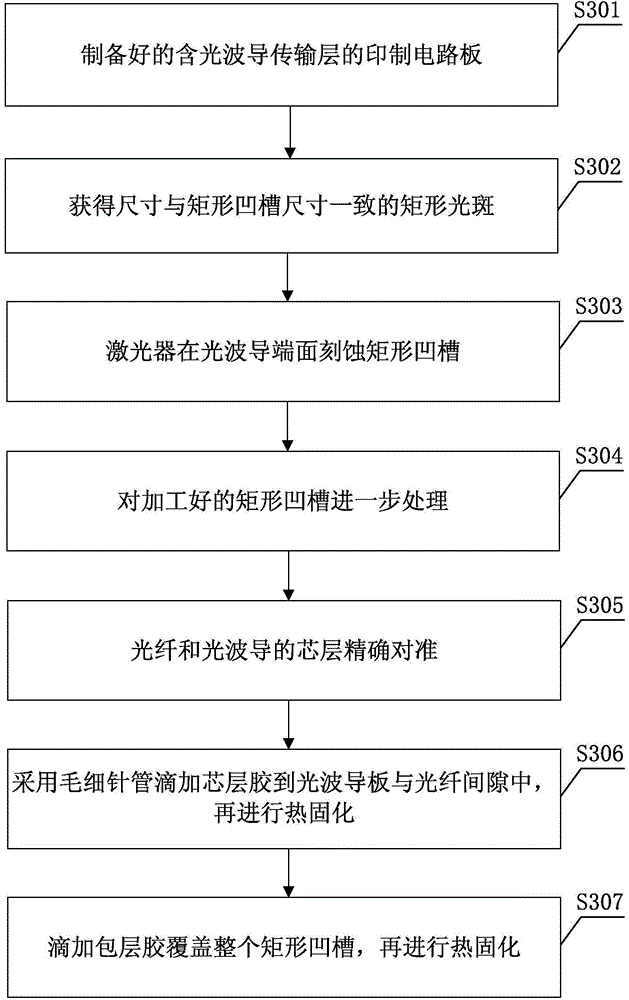

[0067] The coupling connection method between the optical waveguide plate and the optical fiber in this embodiment of this embodiment mainly uses a laser to etch a rectangular groove on the end face of the prepared optical waveguide. The rectangular groove is a kind of connection groove, and the specific shape can be Depending on the specific situation, the optical fiber is embedded in the rectangular groove to realize the butt coupling, and finally the waveguide glue is used for curing and packaging to realize the parallel coupling of the optical waveguide and the optical fiber. This method cleverly applies the micromachining technology to the parallel coupling technology of the optical waveguide plate and the optical fiber, overcomes the alignment deviation of the optical waveguide-fiber connection caused by external forces such as vibration and collision, and avoids the long-term exposure of the connector to the optical fiber. In the air, its end face is susceptible to dust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com