Reflective display device and manufacturing method thereof

A reflective display and manufacturing method technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of low light transmittance, achieve the effect of reducing loss and improving light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

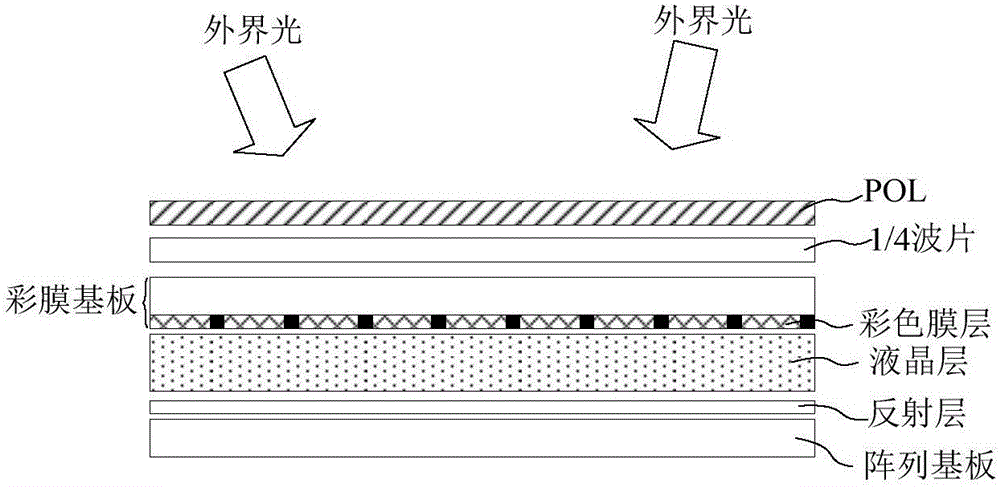

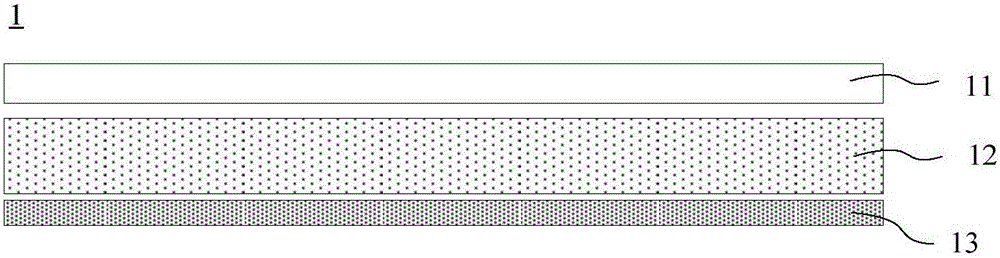

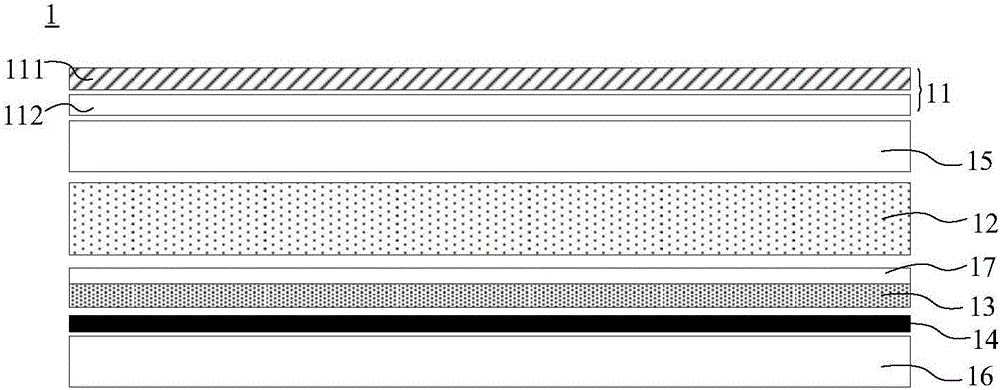

[0043] Such as figure 2 As shown, the embodiment of the present invention provides a reflective display device 1, including: a circular polarizer 11, a liquid crystal (Liquid Crystal, abbreviated as LC) layer 12, and a cholesteric liquid crystal (abbreviated as CLC) Layer 13.

[0044] Among them, the circular polarizer 11 can convert external light into circularly polarized light, where it can be converted into left-handed circularly polarized light and right-handed circularly polarized light.

[0045] Preferably, such as image 3 As shown, the circular polarizer 11 may include: a linear polarizer 111 and a quarter wave plate 112 located below the linear polarizer 111, wherein the optical axis of the quarter wave plate 112 is transparent to the linear polarizer 111. The axis is 45 degrees. The external light may pass through the linear polarizer 111 and then become linearly polarized light, and the linearly polarized light may become circularly polarized light after passing throu...

Embodiment 2

[0080] reference Picture 9 The embodiment of the present invention provides a manufacturing method of a reflective display device, including:

[0081] S101, forming a cholesteric liquid crystal layer on the second substrate.

[0082] Wherein, the cholesteric liquid crystal layer is used to reflect left-handed circularly polarized light without reflecting right-handed circularly polarized light, or used to reflect right-handed circularly polarized light without reflecting left-handed circularly polarized light, wherein, the cholesteric liquid crystal The layer is divided into a plurality of reflecting units, each of the reflecting units includes a plurality of reflecting subunits, and the pitch of the cholesteric liquid crystal in different reflecting subunits is different.

[0083] Preferably, this step may include:

[0084] Firstly, a barrier wall is made on the second substrate with an opaque material to separate multiple accommodating cavities. Among them, the opaque material ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com