Multiaxial Fatigue Life Prediction Method and Fatigue Life Reliability Evaluation Method of Electric Spindle

A fatigue life, motorized spindle technology, applied in CAD circuit design, design optimization/simulation, special data processing applications, etc., can solve problems such as inability to respond to the motorized spindle, and achieve the effect of avoiding high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

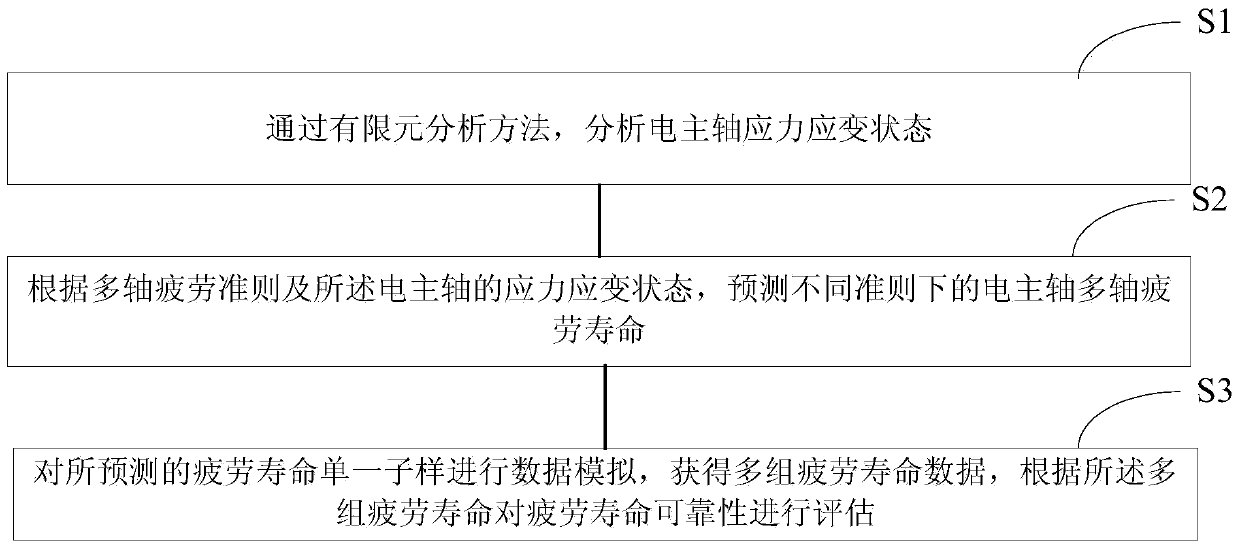

[0057] The multi-axis fatigue life prediction method of the electric spindle of the present invention comprises the following steps:

[0058] Step S1, analyzing the stress and strain state of the electric spindle by means of finite element analysis.

[0059] Before this step, it may also include: establishing a three-dimensional finite element model of the electric spindle. Specifically, based on the two-dimensional drawing of the main shaft, the electric spindle model can be established in the solidworks three-dimensional modeling software, and the structure of the model can be simplified; metamodel.

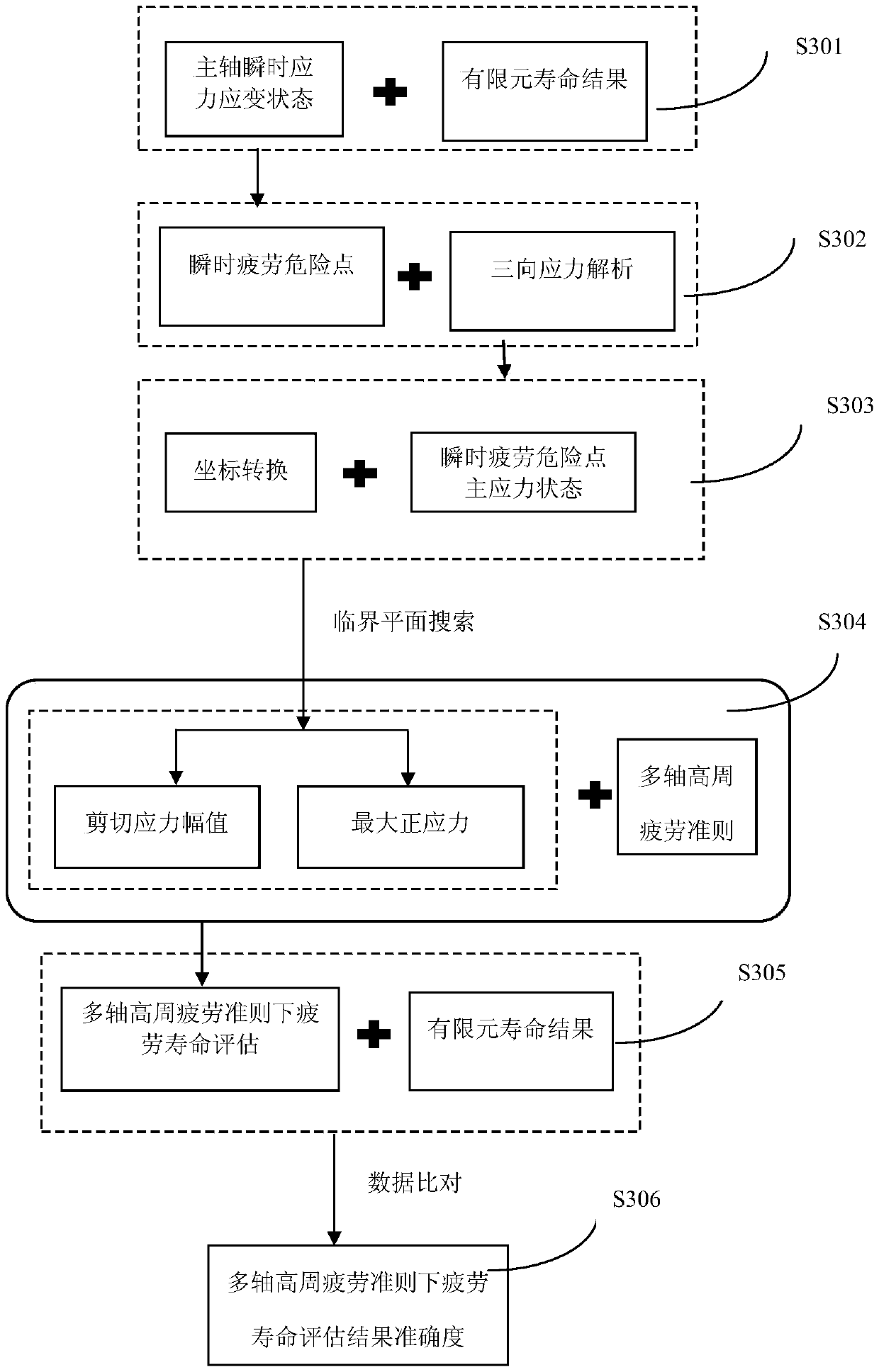

[0060] In this step, the stress-strain state of the electric spindle is analyzed, which specifically includes the following steps:

[0061] Step S101, under consideration of load conditions such as shear stress or compressive stress, torque and bearing support, perform static mechanical analysis on the electric spindle to determine the instantaneous stress and strain state of...

Embodiment

[0073] This embodiment provides a method for predicting the multi-axis fatigue life of an electric spindle and evaluating the reliability of the fatigue life. In this embodiment, the A204 turning electric spindle is taken as an example, and multi-axis fatigue life prediction and reliability analysis are carried out for this type of electric spindle. The motorized spindle and spindle described below all refer to the settings here.

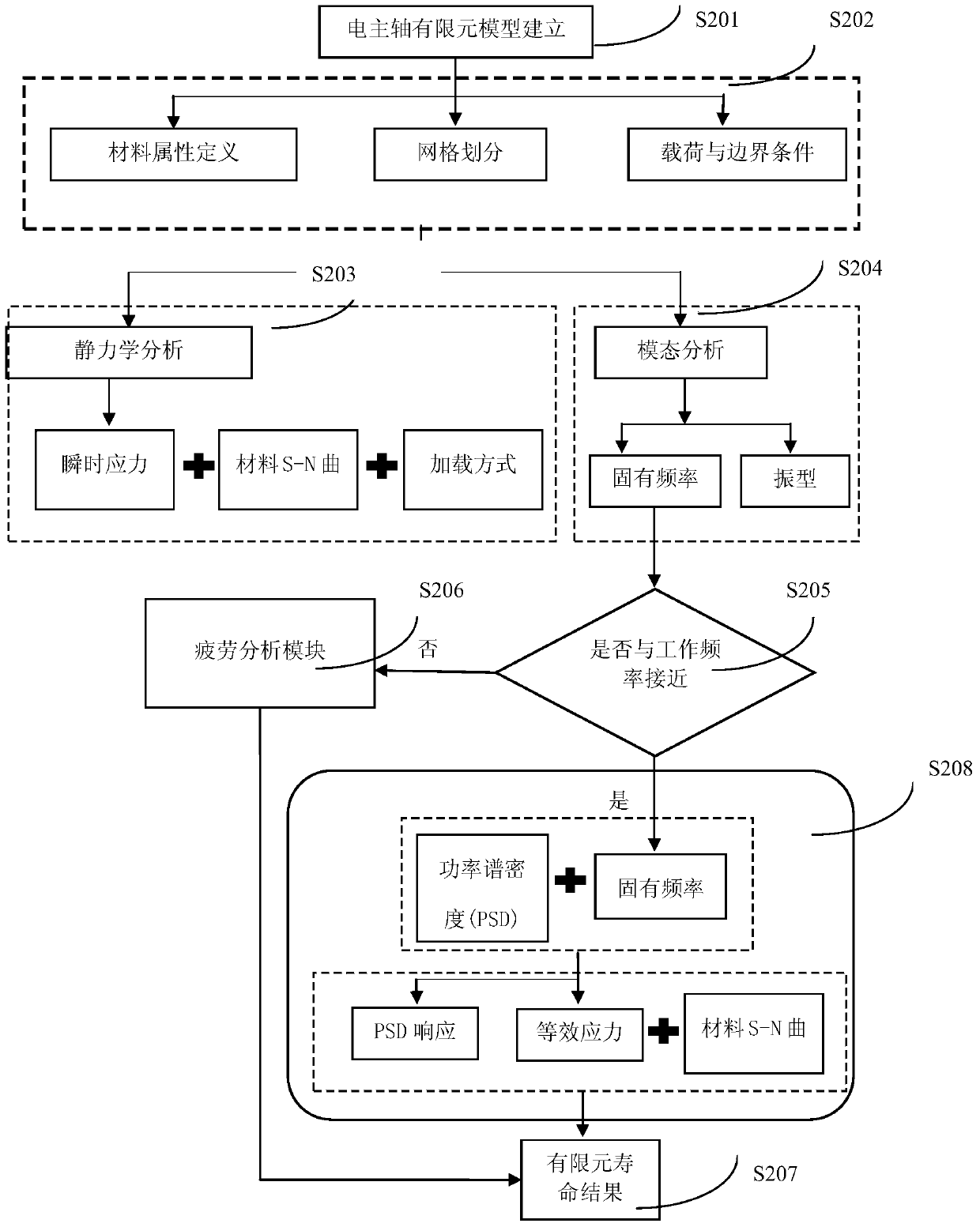

[0074] figure 2 It is a schematic diagram of the multi-axis fatigue life prediction flow chart of the electro-spindle finite element simulation of this embodiment. Such as figure 2 As shown, the multiaxial fatigue life prediction method of this embodiment includes the following steps:

[0075] Step S201, establishing a finite element model of the electric spindle.

[0076] In this step, according to the 2D CAD drawing of the motorized spindle, the 3D solid modeling of the A204 turning motorized spindle is completed in the 3D modeling software ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com