A permanent magnet brushless DC motor with a built-in controller for range hoods

A permanent magnet brushless DC and range hood technology, which is applied in the direction of connection with control/drive circuits, electromechanical devices, electrical components, etc., can solve the problems that brushless DC motors cannot be used alone and are inconvenient to use, and achieve noise reduction Significantly, the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

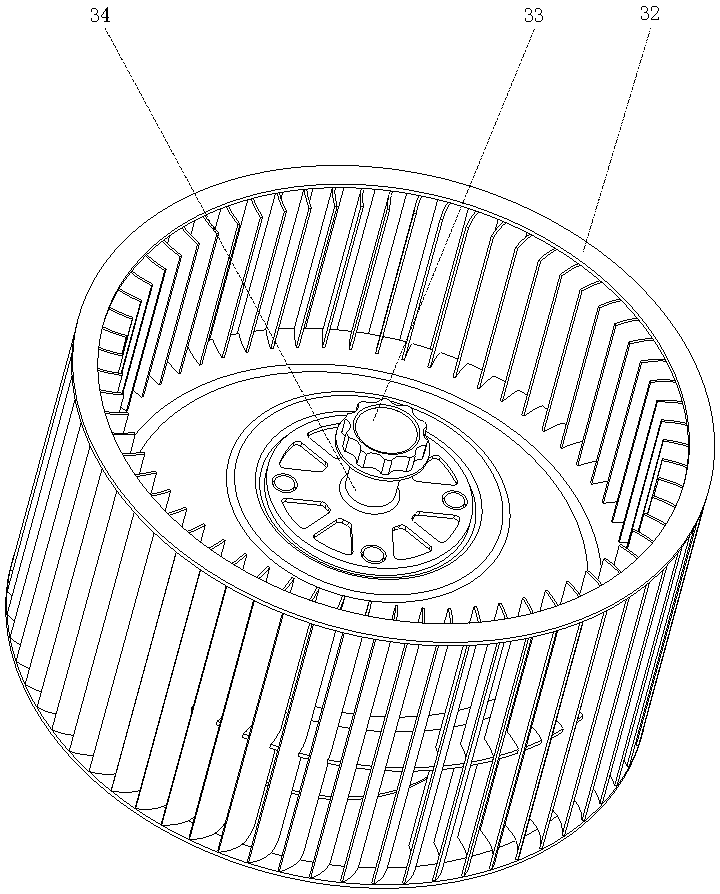

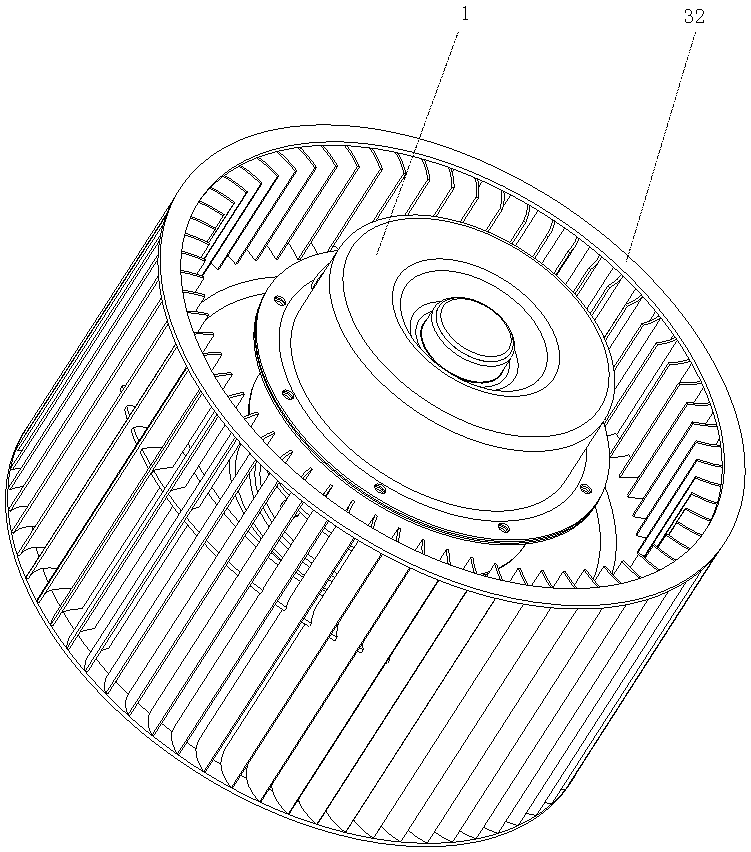

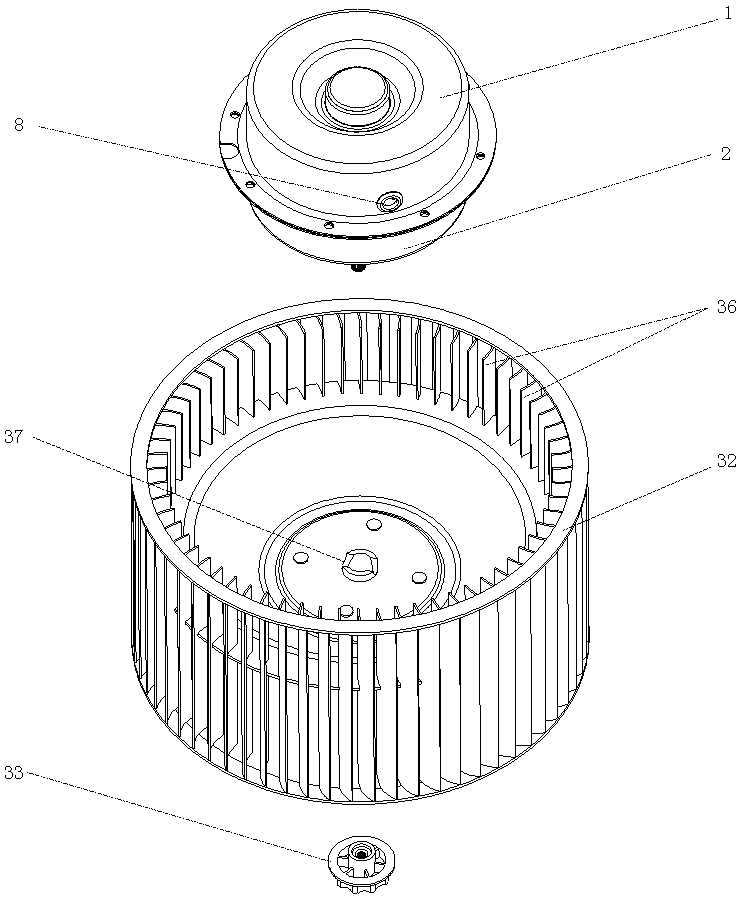

[0066] The present invention as Figure 1 to Figure 18 shown. The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing:

[0067] A permanent magnet brushless DC motor with a built-in controller for range hoods, which is composed of an upper end cover part and a lower end cover part, and the lower end cover part includes: a lower end cover shell 2, a rotating shaft 3, a sheathed stator core body 7, Wire package 9, rotor core body 17, NdFeB permanent magnet block 16, upper bearing 14, lower bearing 15, the upper end cover part includes: upper end cover shell 1, inner lining bracket 5, cover plate 6, PCB board 12, dual core Single-chip microcomputer 20, drive chip 23, VMOS power tube 21, electrolytic capacitor 22, cable 4, described lower end cover housing 2 and upper end cover housing 1 are all hollow cylinders formed by one stamping, wherein the lower end cover housing 2 There is a lower bearing supporting cylindrical step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com