Preparation method of glass wound protective gel

A gel and wound surface technology, applied in the field of medical products, can solve problems such as severe pain, rapid increase of local pH, and patient irritation, and achieve the effect of no side effects, good repair effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

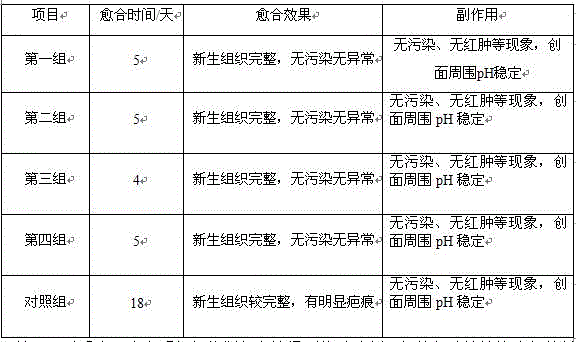

Examples

Embodiment 1

[0017] A preparation method of glass wound protection gel, comprising the following steps:

[0018] Step 1, add 0.5 parts of gelatin and 1 part of gum arabic in parts by weight to 20 parts of water for injection, heat and stir to mix evenly, the heating temperature is 60°C, the stirring speed is 80 rpm, and the stirring time is 30 minutes, and then Add 2 parts of aloe extract and 1 part of lecithin, continue to stir and mix evenly to obtain a mixed solution 1;

[0019] Step 2, 0.2 part of polyethylene glycol 600, 5 parts of sodium hyaluronate gel, 3 parts of bioactive glass powder, 0.1 part of sodium acetate, 0.5 part of microcrystalline cellulose and hypromellose in parts by weight Add 1 part to 5 parts of water for injection, heat and stir for 20 minutes under a vacuum condition of 0.02 MPa, the heating temperature is 30°C, and the stirring speed is 60 rpm to obtain the mixed solution 2;

[0020] Step 3: Heat the mixed solution 1 to 40° C., add the mixed solution 2 under st...

Embodiment 2

[0022] A preparation method of glass wound protection gel, comprising the following steps:

[0023] Step 1, add 0.6 parts of gelatin and 2 parts of gum arabic in parts by weight to 25 parts of water for injection, heat and stir to mix evenly, the heating temperature is 63°C, the stirring speed is 85 rpm, the stirring time is 36 minutes, and then Add 3 parts of aloe extract and 2 parts of lecithin, continue to stir and mix evenly to obtain a mixed solution 1;

[0024] Step 2, 0.3 part of polyethylene glycol 600, 7 parts of sodium hyaluronate gel, 5 parts of bioactive glass powder, 0.2 part of sodium acetate, 0.6 part of microcrystalline cellulose and hypromellose in parts by weight Add 2 parts to 7 parts of water for injection, heat and stir for 25 minutes under a vacuum condition of 0.06MPa, the heating temperature is 36°C, and the stirring speed is 65 rpm to obtain the mixed solution 2;

[0025] Step 3: Heat the mixed solution 1 to 42°C, add the mixed solution 2 under stirri...

Embodiment 3

[0027] A preparation method of glass wound protection gel, comprising the following steps:

[0028] Step 1, add 0.8 parts of gelatin and 2 parts of gum arabic in parts by weight to 28 parts of water for injection, heat and stir to mix evenly, the heating temperature is 67°C, the stirring speed is 95 rpm, the stirring time is 45 minutes, and then Add 5 parts of aloe extract and 3 parts of lecithin, continue to stir and mix evenly to obtain a mixed solution 1;

[0029] Step 2, 0.4 part of polyethylene glycol 600, 8 parts of sodium hyaluronate gel, 6 parts of bioactive glass powder, 0.2 part of sodium acetate, 0.7 part of microcrystalline cellulose and hypromellose in parts by weight Add 2 parts to 9 parts of water for injection, heat and stir for 26 minutes under a vacuum condition of 0.04MPa, the heating temperature is 38°C, and the stirring speed is 65 rpm to obtain the mixed solution 2;

[0030] Step 3: Heat the mixed solution 1 to 48°C, add the mixed solution 2 under stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com