Forming device for hollow fiber composite membrane

A fiber composite and forming device technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of falling off, insufficient membrane filament strength, and many broken filaments, so as to improve the adsorption force and improve the safety of use. Sex, the effect of avoiding rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

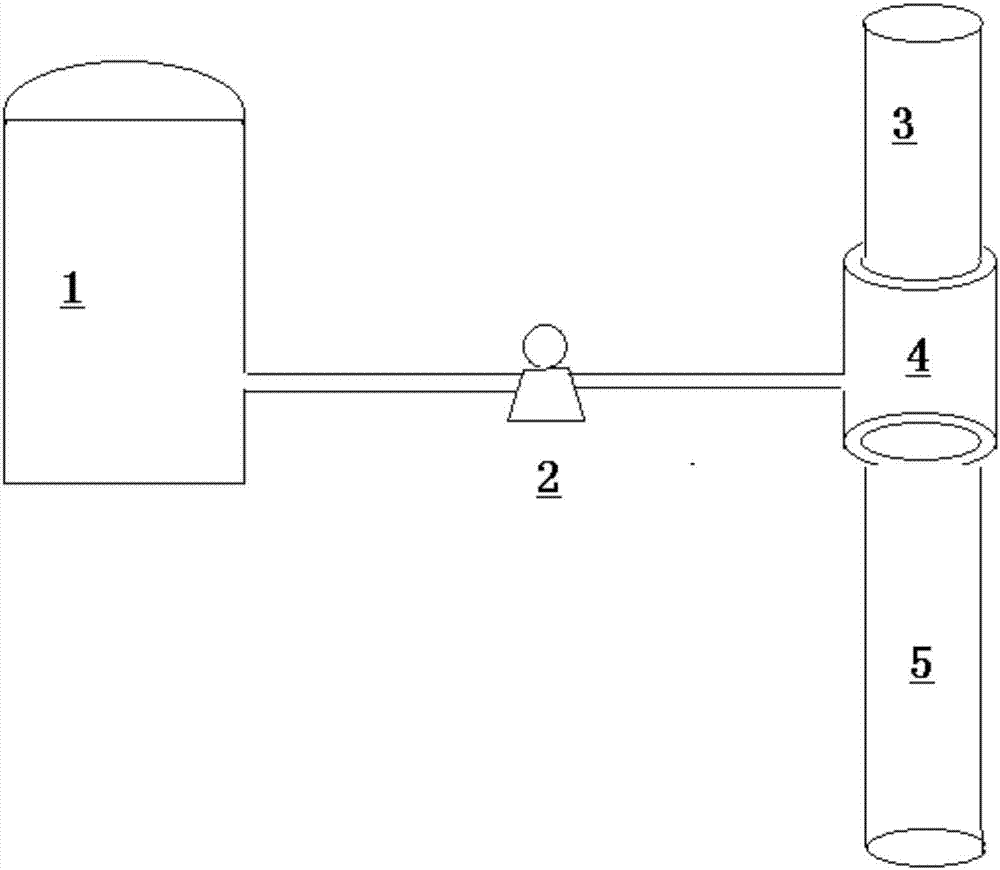

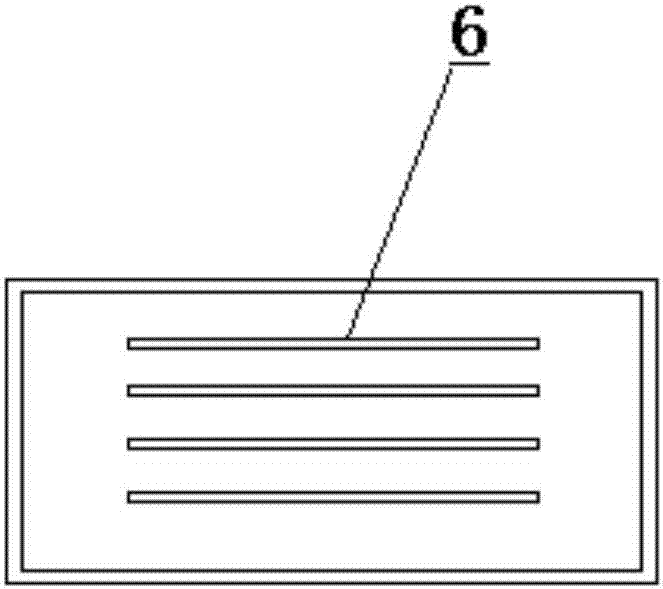

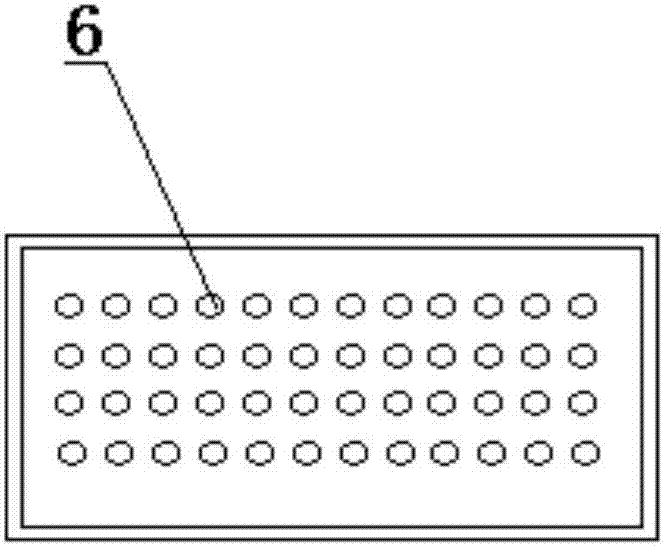

[0048] The polyvinylidene fluoride (PVDF) powdery raw material is mixed with a solvent and a pore-forming agent in a certain proportion to form a membrane-forming liquid, and the film-forming liquid is squeezed into a strip-shaped annular sleeve through a metering pump 2 . At the same time, the hollow cotton rope with an outer diameter of 2mm is introduced into the device, and the hollow rope 3 or 5 is pulled by a tractor at a certain speed. After the hollow rope 3 or 5 passes through the device, the surface is evenly coated with a layer of film-making liquid. A nascent hollow fiber composite membrane is formed. After the primary hollow fiber composite membrane is cured in a gel bath, a hollow fiber composite membrane product is obtained. The outer diameter of the prepared hollow fiber membrane was 2.5 mm, and its peeling strength was 8.2 bar.

Embodiment 2-4

[0050] Polysulfone (PS) (implementation example 2), polyethersulfone (PES) (implementation example 3), polyacrylonitrile (PAN) (implementation example 4) powdered raw materials are mixed in a certain proportion with solvent and pore-forming agent respectively, A film-making liquid is formed, and the film-making liquid is extruded into the annular sleeve whose inner surface is strip-shaped through the metering pump 2 . At the same time, the hollow cotton rope with an outer diameter of 2mm is introduced into the device, and the hollow rope 3 or 5 is pulled by a tractor at a certain speed. After the hollow rope 3 or 5 passes through the device, the surface is evenly coated with a layer of film-making liquid. A nascent hollow fiber composite membrane is formed. After the primary hollow fiber composite membrane is cured in a gel bath, a hollow fiber composite membrane product is obtained. The outer diameter of the prepared hollow fiber membrane was 2.5 mm, and the peeling strength...

Embodiment 5-6

[0052] Composite hollow fiber membranes were prepared by the same method and steps as in Examples 1-4. The difference is that the hollow rope 3 or 5 used in the present example 5-6 is nylon and PET. The outer diameter of the prepared hollow fiber membrane was 2.3 mm, and the peeling strength was 8.2 bar and 8.6 bar. It can be seen that under the same conditions, the film-making solution has the strongest adhesion to the cotton substrate among the three substrates.

[0053] In summary, the beneficial effect of the present invention is that the device can greatly enhance the adhesion of the membrane-forming liquid on the surface of the hollow rope 3 or 5, and the surface layer of the membrane is not easy to fall off during the application process in harsh fields such as membrane bioreactors, preventing sewage Leakage reaches standard water. The hollow fiber composite membrane prepared by the device of the present invention has good adhesion and flexibility at the same time thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com