Centrifugal separator for processing slime

A technology for centrifugal concentrator and ore slime, which is applied in centrifuge, solid separation, wet separation, etc., can solve the problems of increasing normal pulsation speed and centrifugal acceleration, and can solve the problem of increasing centrifugal acceleration and realizing separation. Choice, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0036] The invention provides a centrifugal concentrator aiming at the problem that the centrifugal acceleration of the existing centrifugal concentrator increases, and the normal pulsation velocity of the rotary flow increases accordingly.

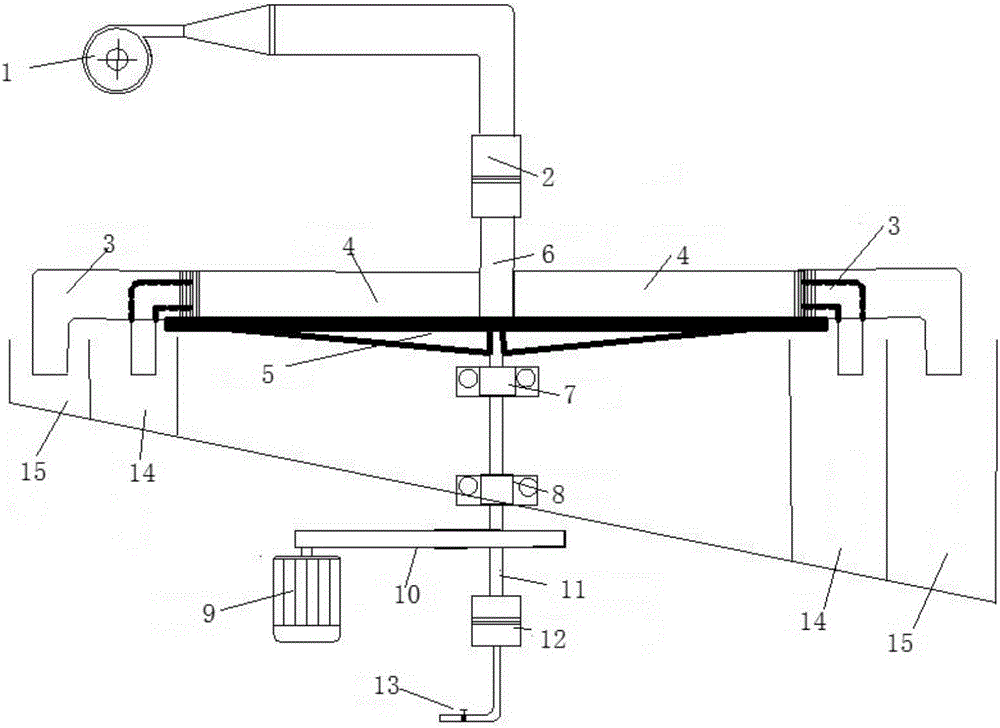

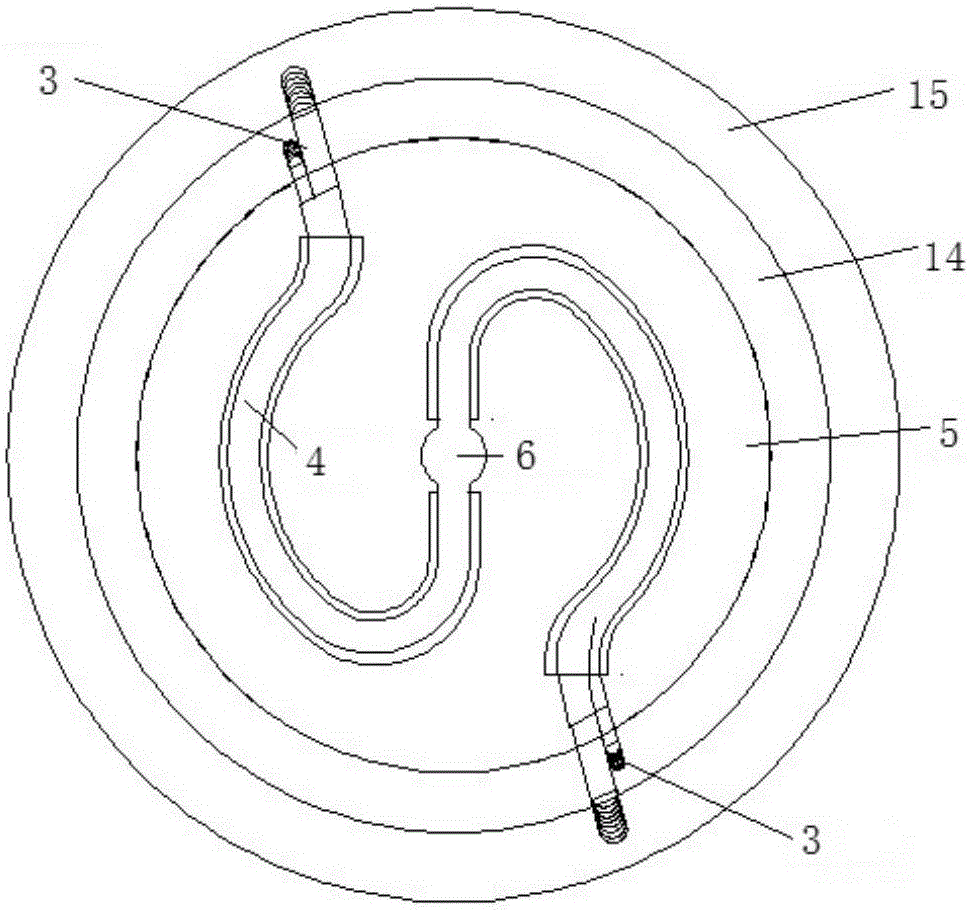

[0037] Such as figure 1 and figure 2 As shown, in the centrifugal concentrator, the sand pump 1 is connected to the slurry rotary connector 2, the slurry rotary connector 2 is connected to the receiver 6, the rotary platform 5 is installed on the hollow transmission shaft 11, and the hollow transmission shaft 11 is installed The upper bearing 7 and the lower bearing 8, the motor 9 drives the hollow transmission shaft 11 through the transmission belt 10; the lower end of the hollow transmission shaft 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com