Deep-circular-groove PET plastic bottle preform injection mold and use method thereof

A technology for injection molds and plastic bottles, applied in applications, household appliances, household components, etc., can solve the problems of hard material, food deterioration, inability to seal bottle caps with water, etc., achieve reasonable mold design, increase water storage performance, extend The effect of water sealing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

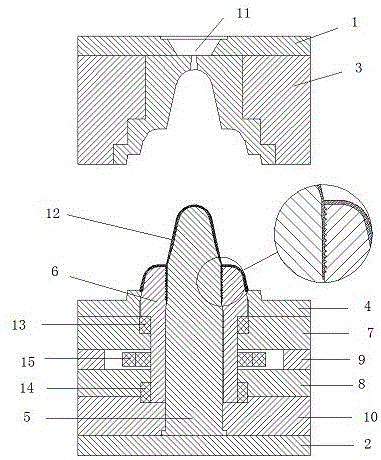

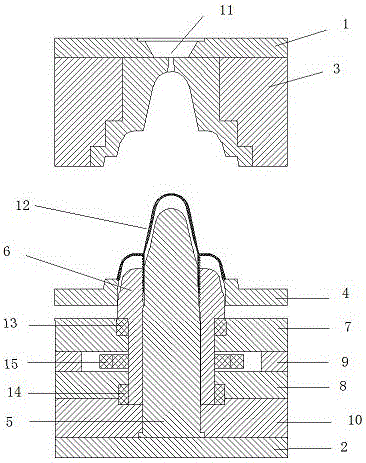

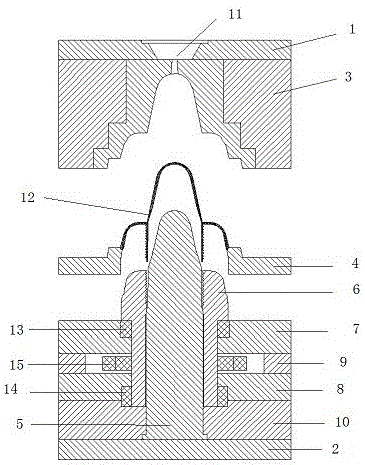

[0014] Refer to the accompanying drawings below figure 1 , figure 2 and image 3 The present invention is further described.

[0015] The using method of deep ring groove PET plastic preform body injection mold, if injection molding machine is vertical mold opening, described mold whole longitudinal setting; If injection molding machine is horizontal mold opening, mold of the present invention can be adjusted to horizontal setting as required.

[0016] The mold includes a first press plate 1 and a second press plate 2 which are bolted to the injection molding machine, a cavity plate 3 in the lower chamber corresponding to the shape of the ring groove plastic preform body 12, and a cavity plate 3 for pushing the plastic The edge of the notch portion of the preform body ring realizes the push plate 4 for product demoulding, the upper outer wall and the mold core 5 corresponding to the shape of the inner wall of the plastic preform body 12, and the upper outer wall is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com