Method for preparing 1,2,3-thiadiazole-4-carboxylic acid

A technology of thiadiazole and dicarboxylic acid, which is applied in the field of compound synthesis, can solve the problems that the synthesis process cannot be enlarged and industrialized, and the synthesis rate is low, and achieve the effect of low price, high synthesis rate and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

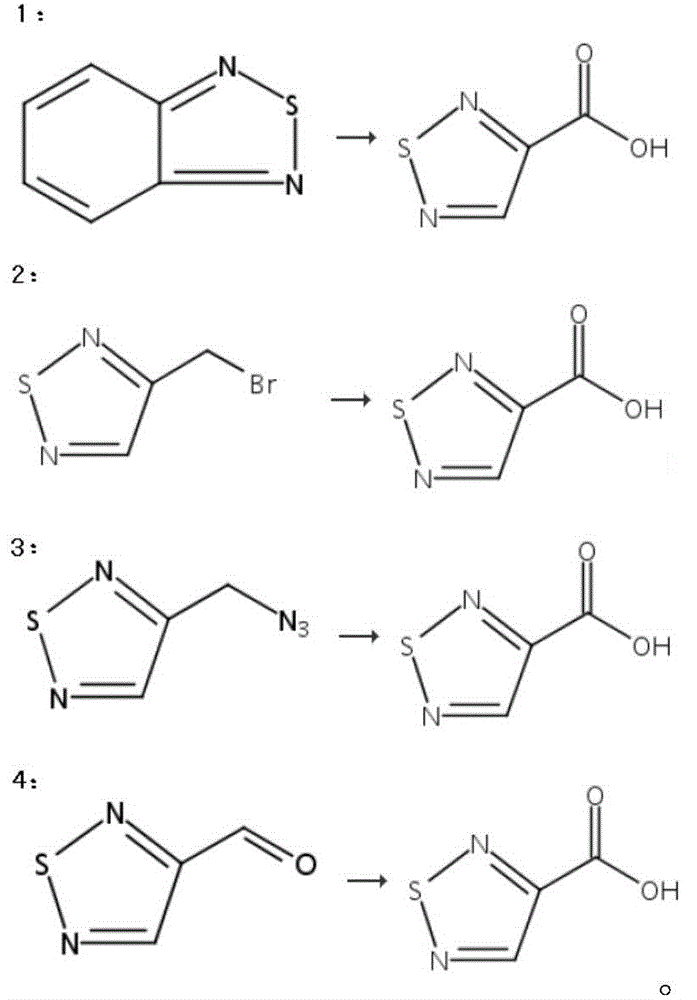

Problems solved by technology

Method used

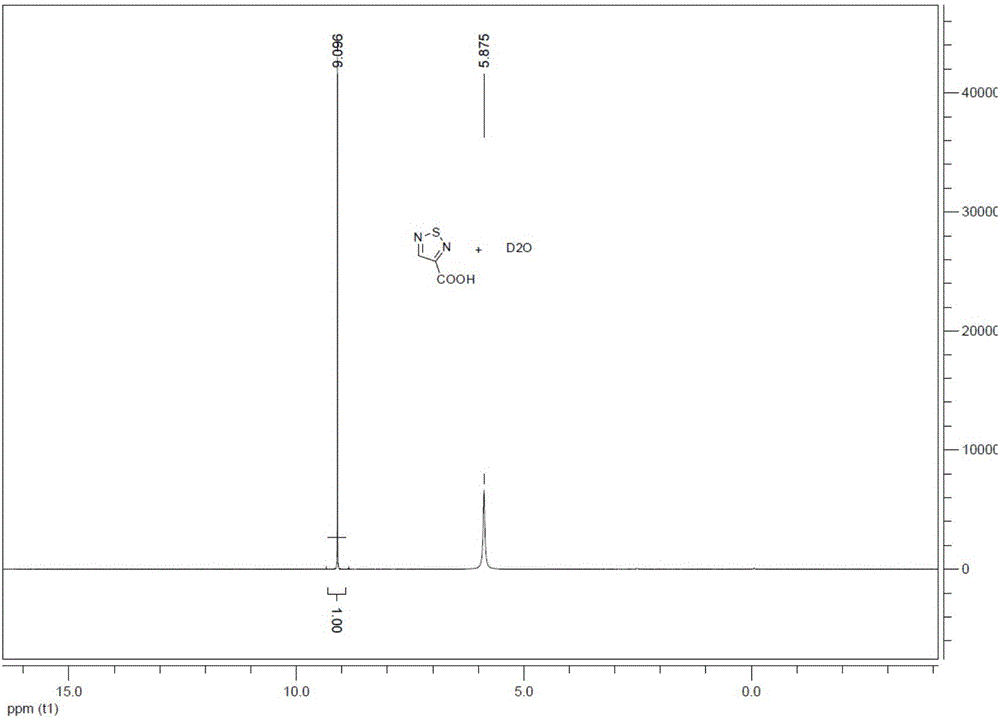

Image

Examples

Embodiment 1

[0020] Into a 10L four-necked flask, add diaminomaleic cyanide: 410g, THF: 3.79L, triethylamine: 1.718kg, cool down to 0°C and slowly add thionyl chloride: 918.68g, dropwise, continue stirring After 6 hours, filter, wash the filter cake with THF, combine the washing liquid with the filtrate, spin dry (rotate to dryness), add 1.5 L of dichloroethane and 5 L of water, and steam distill to obtain 300 g of light yellow solid. Detection: HPLC 220nm 98%, yield of 4,5-dicyano-1,2,3-thiadiazole: 58.1%.

[0021] The reaction formula is:

[0022]

[0023] In a 2L four-neck flask, add water: 600g, slowly drop concentrated sulfuric acid: 600g, make 50% sulfuric acid aqueous solution, then add 4,5-dicyano-1,2,3-thiadiazole: 300g, React at 120°C for 12 hours, cool down to 0°C, stir for 2 hours, and filter to obtain 337.7g of white solid 1,2,3-thiadiazole 4,5-dicarboxylic acid, yield: 88%.

[0024] The reaction formula is:

[0025]

[0026] Put 250g of the white solid into a 500ml f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com