Transparent ABS resin composition with large phase zone dimension and preparation method thereof

A technology of ABS resin and composition, which is applied in the field of transparent ABS resin with large phase area size and its preparation, can solve the problems of not very ideal mechanical properties of transparent resin, poor impact resistance, and needs to be improved, and achieve excellent impact resistance, The effect of good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing a large-phase region size transparent ABS resin composition, the method can adopt bulk polymerization method or solution polymerization method, specifically comprising:

[0038] Step 1: dissolving styrene-butadiene block copolymer or random copolymer in diluent, styrene monomer, (meth)acrylate monomer and vinyl nitrile monomer to prepare raw materials solution mixture;

[0039] Step 2: Add the raw material solution mixture obtained in Step 1 into the reactor, add an initiator and a molecular weight regulator, and carry out a polymerization reaction. The polymerization temperature is preferably 120-140°C, and the polymerization time is preferably 1-8 hours. After completion, the large-phase region size transparent ABS resin composition is obtained through devolatilization.

[0040] According to the present invention, the diluent includes aromatic hydrocarbons, aliphatic hydrocarbons, ketone hydrocarbons, ester c...

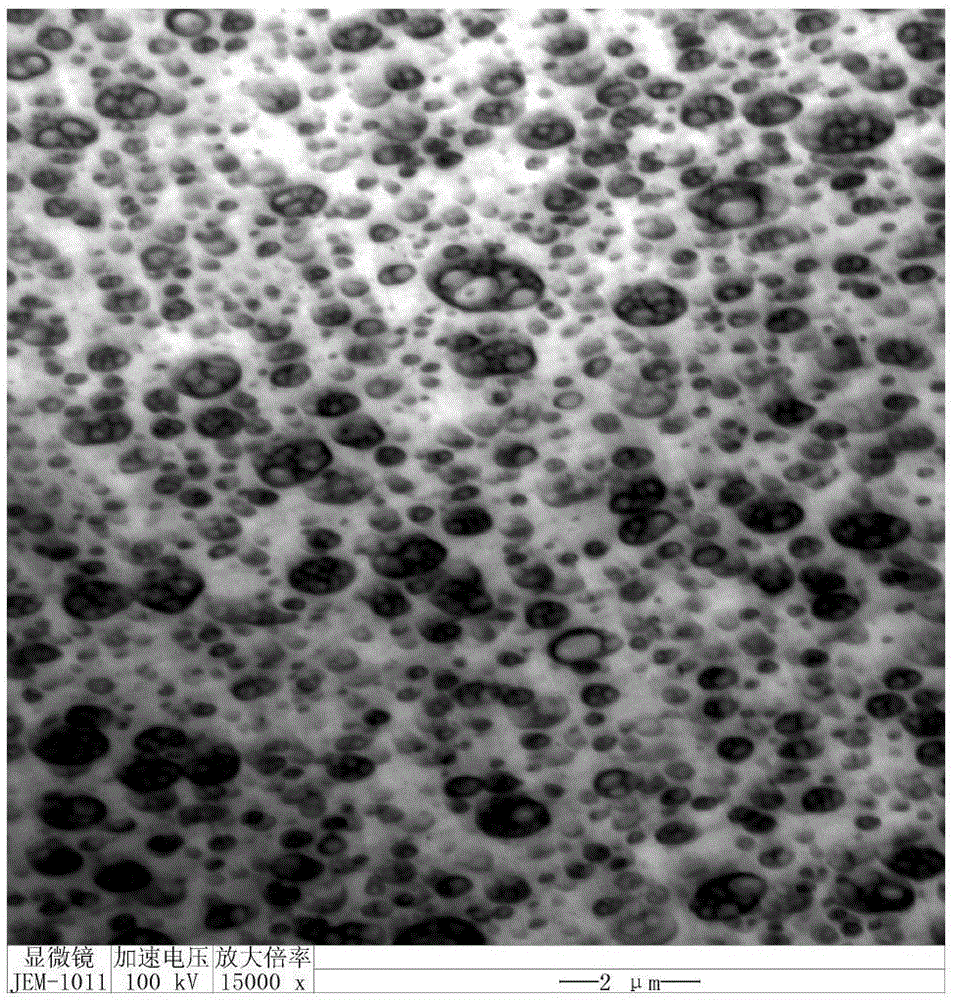

Embodiment 1

[0056] Weigh 10 parts of styrene-butadiene block copolymer (the weight of styrene skeleton accounts for 24% of the total weight of styrene-butadiene copolymer) and dissolve in 41 parts of xylene, 25.5 parts of styrene, 59.5 parts of methyl Methyl acrylate and 5 parts of acrylonitrile to obtain a mixture. After completely dissolving, the mixture was added to the reaction kettle, and at the same time, 500 ppm of di-tert-butyl peroxide was added. Under the condition of nitrogen protection, the polymerization reaction was carried out. The reaction temperature was 130 ° C. The reaction time was 150 minutes. After the reaction, the volatile components were removed to obtain a transparent rubber-modified styrene resin composition, and the monomer conversion rate was 61%.

[0057] The obtained transparent rubber-modified styrene-based resin composition was molded into sheets of 120×65×3.5mm and 100×65×1mm on a flat vulcanizing machine at 180°C, and cut into impact splines and tensile s...

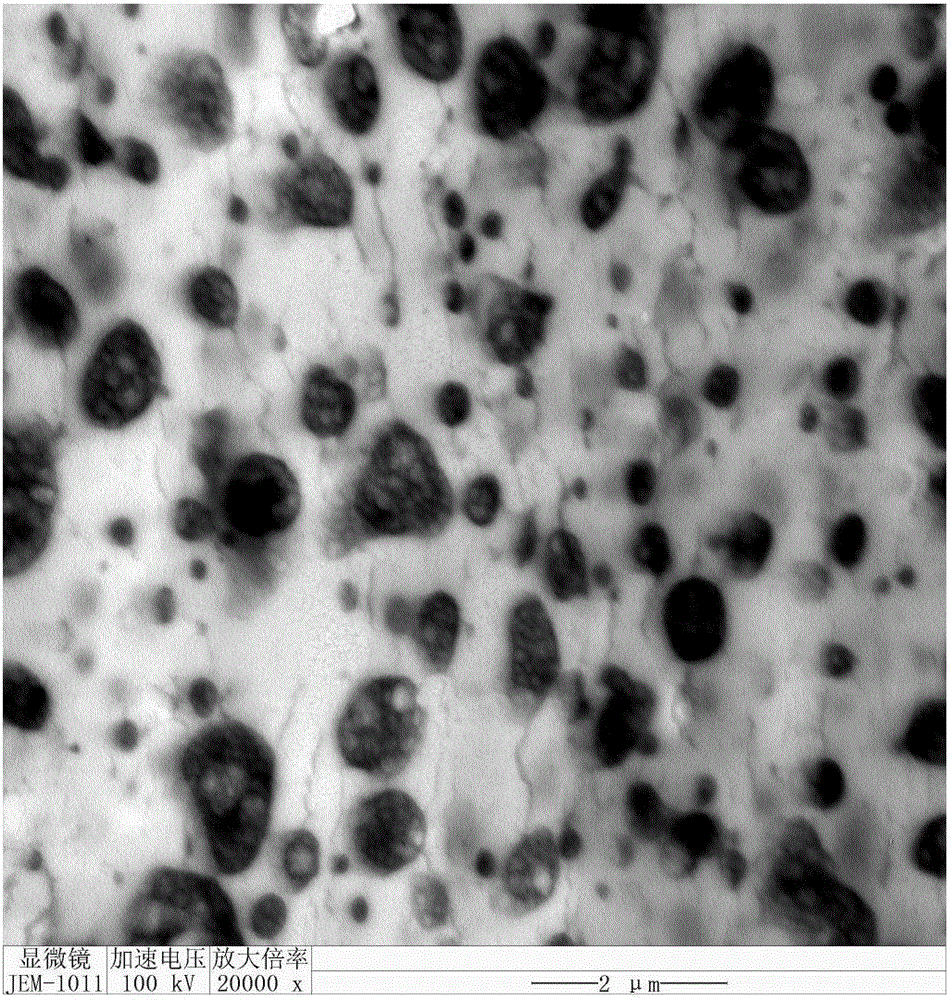

Embodiment 2

[0059] Weigh 10 parts of styrene-butadiene block copolymer (the weight of styrene skeleton accounts for 24% of the total weight of styrene-butadiene copolymer) and dissolve in 41 parts of xylene, 25.5 parts of styrene, 59.5 parts of methyl In methyl acrylate and 5 parts of acrylonitrile, the mixture was obtained, and after complete dissolution, the mixture was added to the reaction kettle, and 500 ppm of di-tert-butyl peroxide and 1500 ppm of tert-dodecyl mercaptan were added at the same time. Under the condition of nitrogen protection, the For the polymerization reaction, the reaction temperature was 130° C., and the reaction time was 150 minutes. After the reaction, the volatile components were removed to obtain a transparent rubber-modified styrene resin composition, and the monomer conversion rate was 67%.

[0060] The obtained transparent rubber-modified styrene-based resin composition was molded into sheets of 120×65×3.5mm and 100×65×1mm on a flat vulcanizing machine at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com