Gas ejector and ultrasonic cleaning device

A technology of cleaning device and transmitter, which is applied in the ultrasonic field, can solve the problems of small impact force and friction force of vibration transmission, difficult to thoroughly clean stubborn dirt, low ultrasonic intensity, etc., and achieve high impact force and friction force, good washing effect, Uniform effect of impact force and friction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

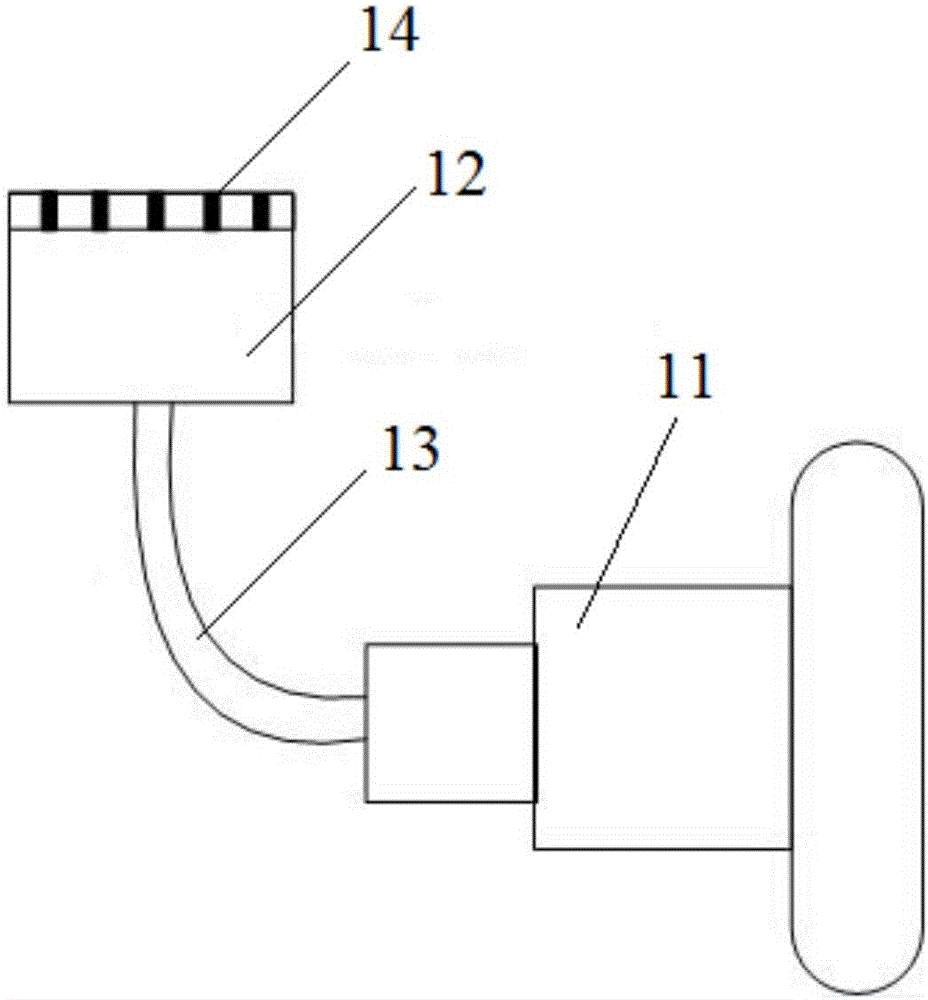

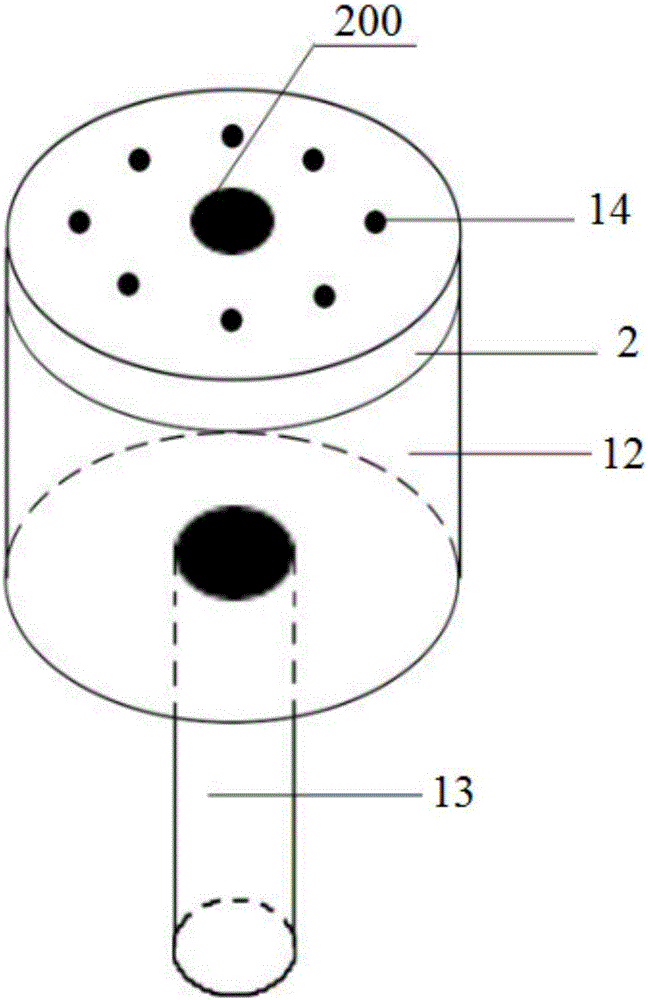

[0053] The ultrasonic cleaning device in this embodiment includes four air holes 14 through which gas with a pressure of 10KPa is introduced.

Embodiment 2

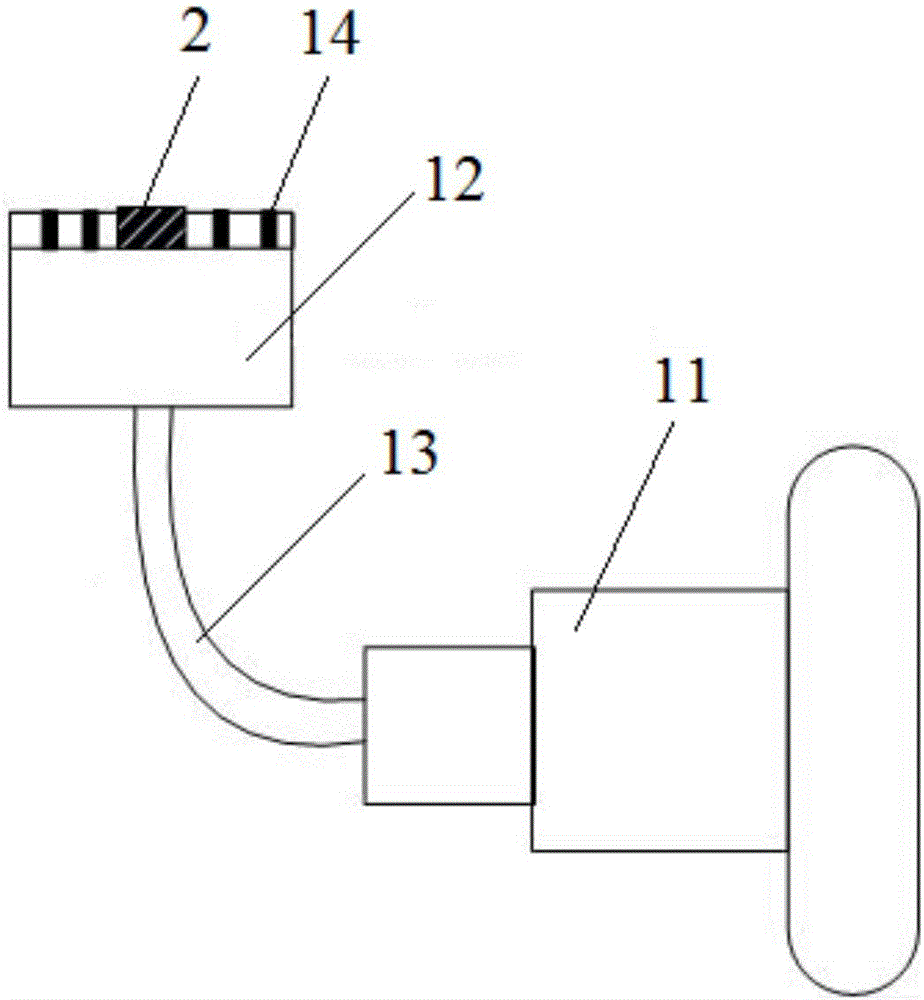

[0055] The ultrasonic cleaning device in this embodiment includes 8 air holes 14 through which gas with a pressure of 10KPa is introduced.

Embodiment 3

[0057] The ultrasonic cleaning device in this embodiment includes 8 air holes 14 through which gas with a pressure of 5KPa is introduced.

[0058] The ultrasonic emitting head devices shown in Examples 1-3 were respectively installed in the washing machine to clean the same objects to be cleaned. After washing for about 30 minutes, measure the cleanliness of the washed clothes, and the obtained data are shown in the table below.

[0059] Table 1 - Cleaning Results Test Form

[0060] test subject

[0061] It can be seen from Table 1 that the more air holes 14 are provided per unit volume, the better the washing effect will be. Or the greater the pressure of the gas fed into the air hole 14, the better the washing effect. The more the number of air holes 14 set per unit volume, the greater the number of bubbles generated by the gas, the greater the pressure of the gas fed by the gas emitter, and the greater the impact force generated by the bubble rupture, so the was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com