Prefabricated rectangular steel tube concrete composite truss bridge and its construction method

A rectangular steel pipe and concrete technology, which is applied in the erection/assembly of bridges, truss bridges, bridges, etc., can solve the problems of difficult to guarantee the quality of on-site concrete pouring, slow bridge erection speed, high material transportation costs, etc., and achieve easy to guarantee processing quality and use The effect of long life and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

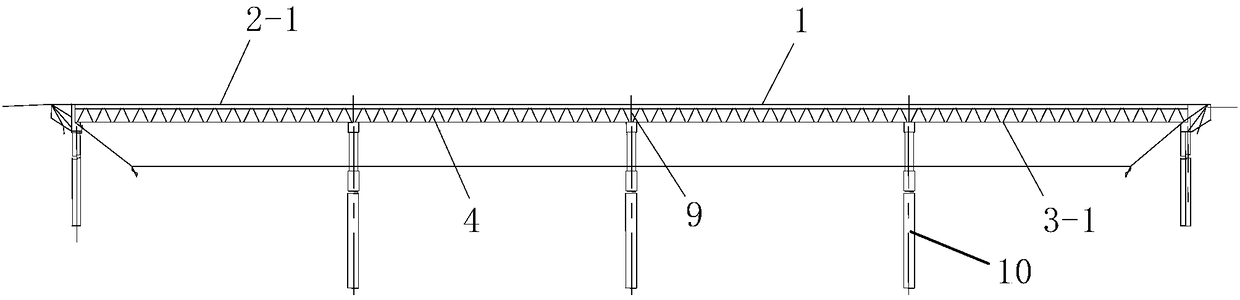

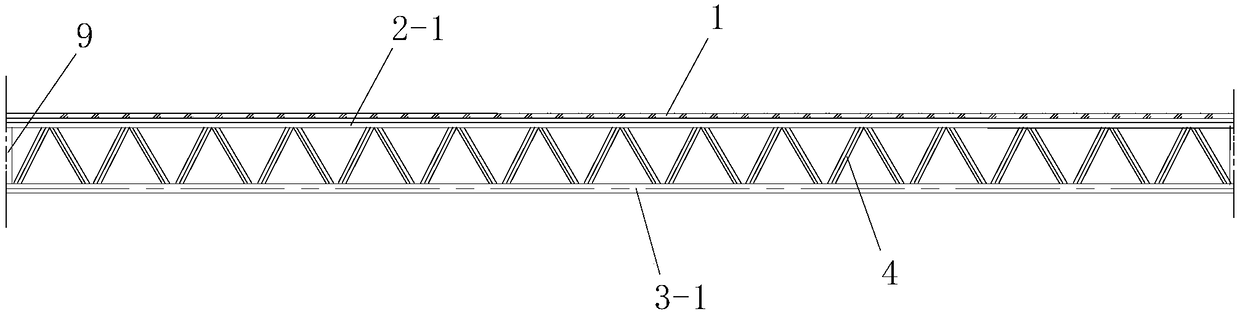

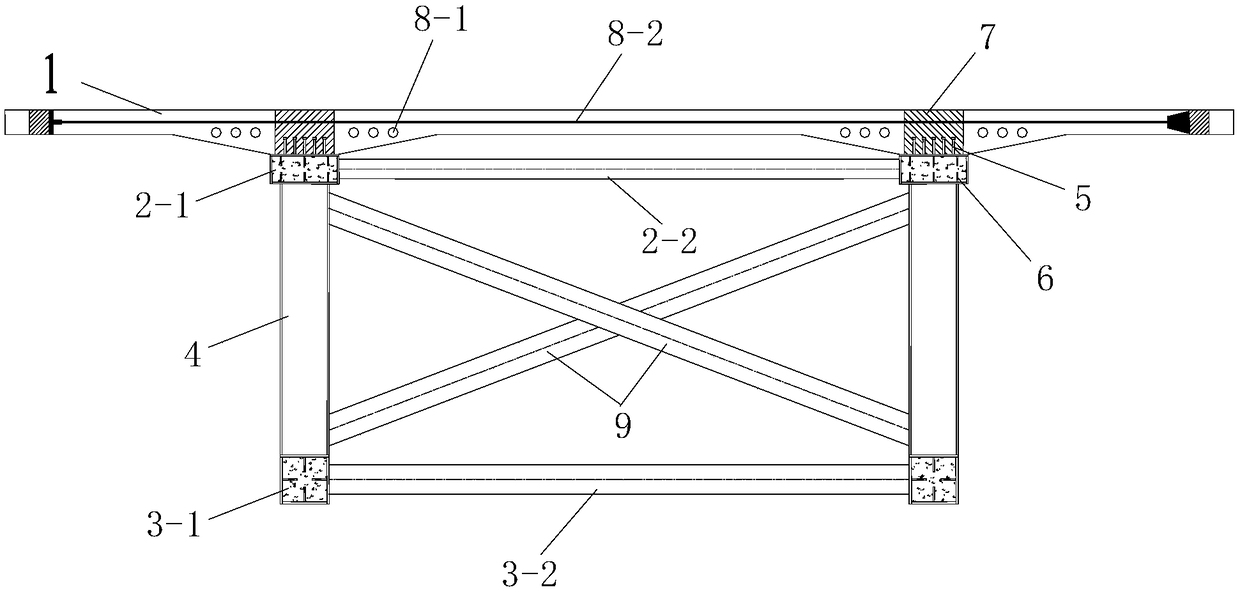

[0053] like figure 1 A prefabricated rectangular steel tube concrete composite truss bridge shown includes a bridge lower support structure, an assembled main girder supported on the bridge lower support structure and a prefabricated bridge deck 1 installed on the assembled main girder , the lower supporting structure of the bridge includes a plurality of main girder lower supporting structures 10 arranged from front to rear along the longitudinal bridge direction, the fabricated main girder is a rectangular steel tube concrete composite truss and is connected to the prefabricated bridge deck 1 by shear force Key 5 to connect; combine figure 2 and image 3 , the rectangular concrete-filled steel pipe composite truss is assembled from a plurality of longitudinal trusses arranged along the longitudinal bridge direction, and the plurality of longitudinal trusses are arranged side by side along the transverse bridge direction from left to right, and each of the longitudinal trus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com