Water cooling method for motor

A technology of water cooling and water pipes, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing production difficulty and manufacturing cost, unsatisfactory heat dissipation and cooling effect, complex structure, etc., to improve heat dissipation effect, prevent cracks, The effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

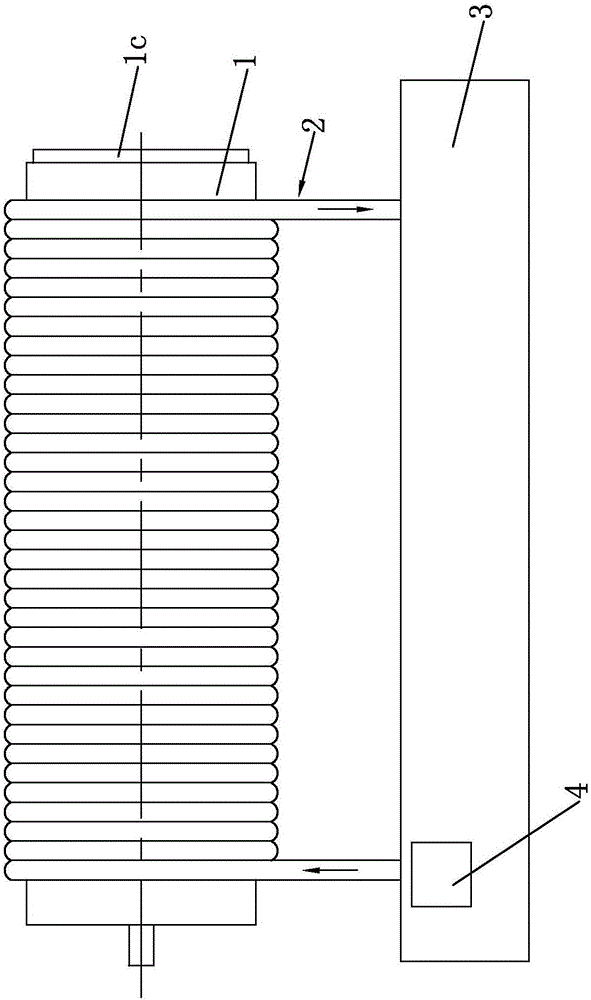

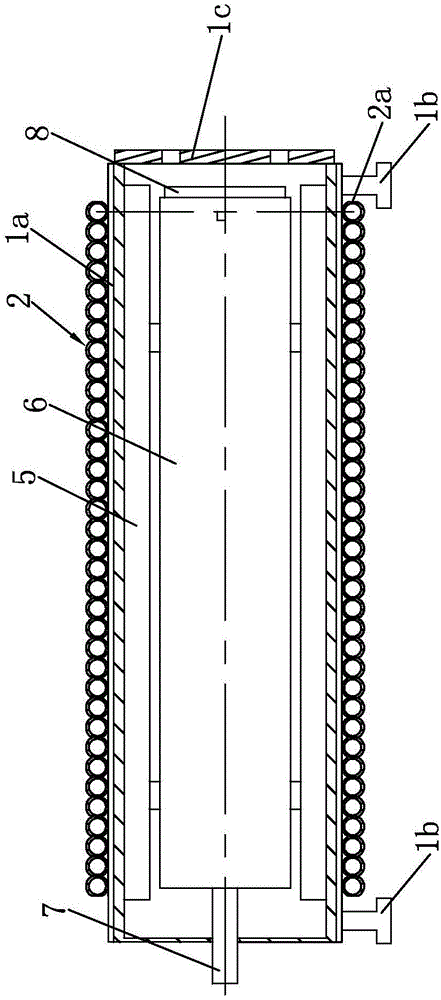

[0023] Such as figure 1 , 2 As shown, a water cooling method for a motor includes a casing 1 and a heat dissipation fan 8, wherein the casing 1 is an aluminum casting, and a group of axial cooling grooves 1a are evenly distributed on the outer wall of the casing 1 along the circumferential direction, and the two ends of the bottom of the casing 1 are respectively There is a mounting bracket 1b. The stator 5 is installed in the stator installation groove on the inner wall of the housing 1, and the stator rotatably cooperates with the rotor 6, and its specific installation structure is in the prior art. The output shaft 7 at one end of the rotor 6 passes through the through hole on the casing 1, and there is a cooling fan 8 at the other end of the rotor. hole. When the motor is working, the heat in the motor casing is mainly discharged from the cooling fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com