Production method of multi-flavor finished product egg

A production method and finished product technology are applied in the production field of various flavored finished eggs, which can solve the problems of easily broken eggshells, affecting the integrity of cooked eggs and production costs, and achieve the advantages of short production cycle, less bacterial infection, and extended shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

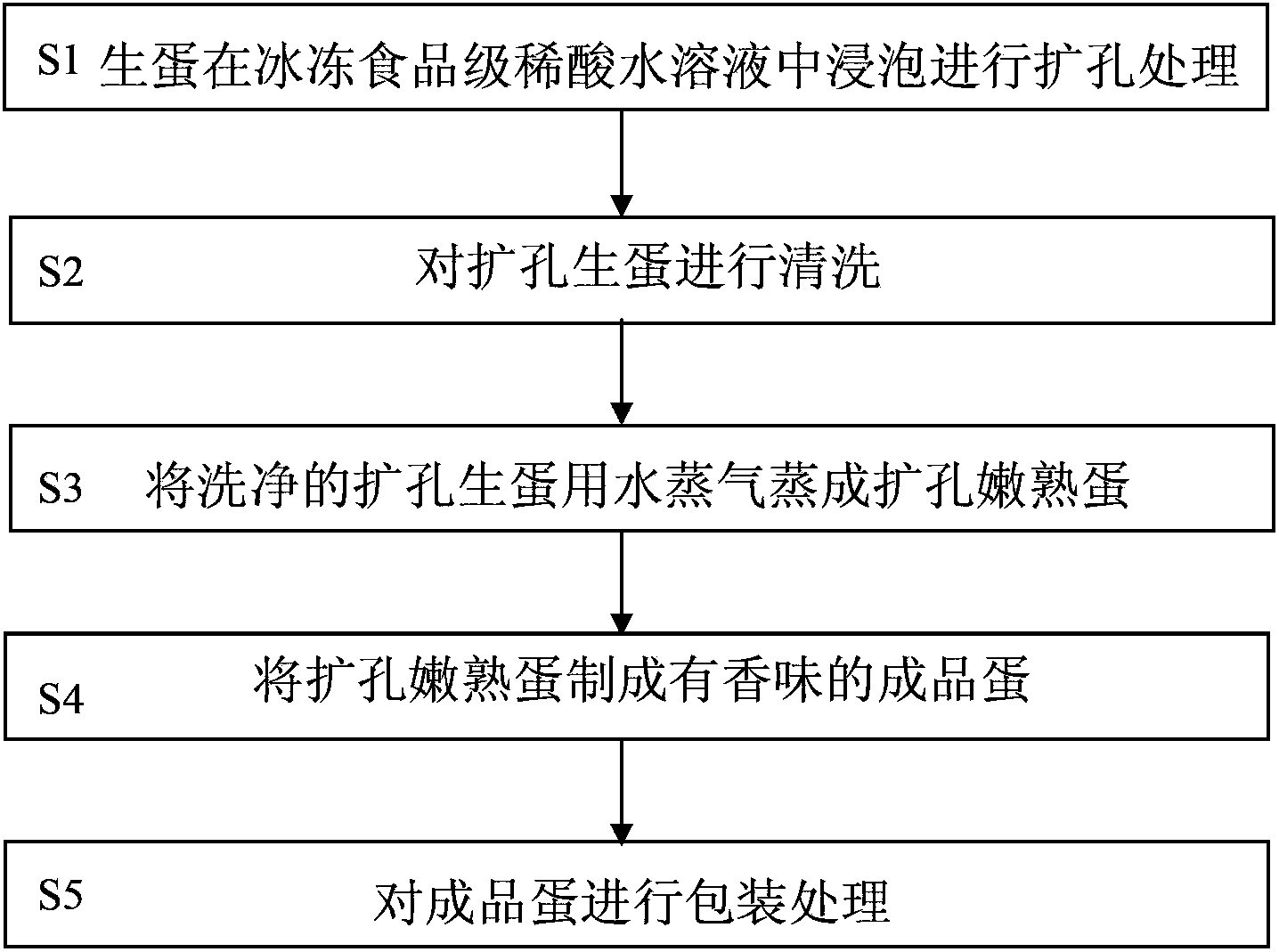

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

[0028] see figure 1 , the preparation method of various fragrance finished eggs of the present invention comprises the following steps:

[0029] S1. Reaming raw eggs: Soak raw eggs in a container filled with frozen (below 0°C) food-grade dilute acid solution for 5-8 minutes, and use the principle of thermal expansion and contraction to make the food-grade dilute acid solution The eggshell is subjected to pore-enlarging treatment, so that the capillary pores on the surface of the eggshell are expanded into large pores, and become an expanded egg.

[0030] The food-grade dilute acid aqueous solution refers to food-grade hydrochloric acid aqueous solution or edible acetic acid aqueous solution, wherein the food-grade hydrochloric acid in the food-grade hydrochloric acid aqueous solution accounts for 0.35%-0.70% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com