An Improved Intensive Wet Process Equipment

A wet process equipment and intensive technology, applied in the field of wet process equipment, can solve problems such as inability to flow back, inaccurate added amount, error between added amount and set added amount, etc., to save site space, save upper space, and ensure accuracy degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The technical solution in the embodiment will be specifically, clearly and completely described below in conjunction with the drawings in the embodiment.

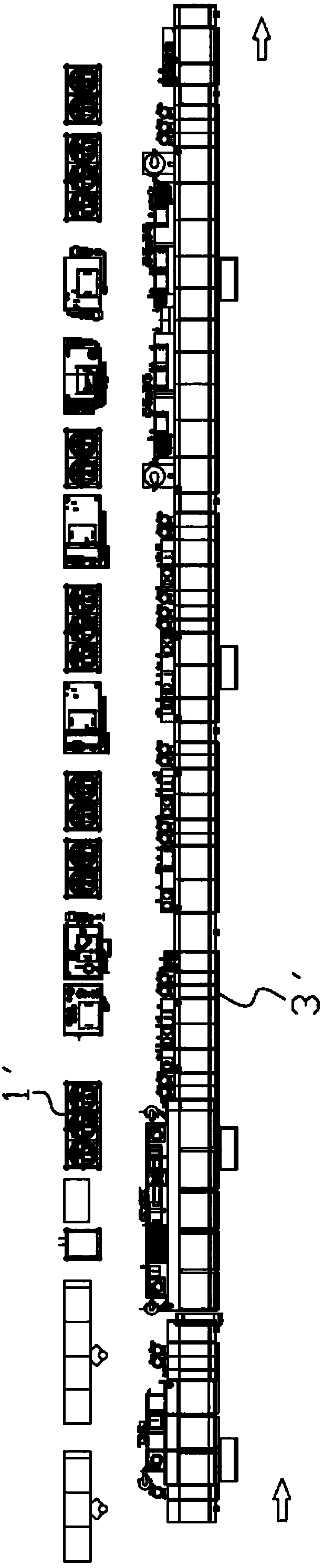

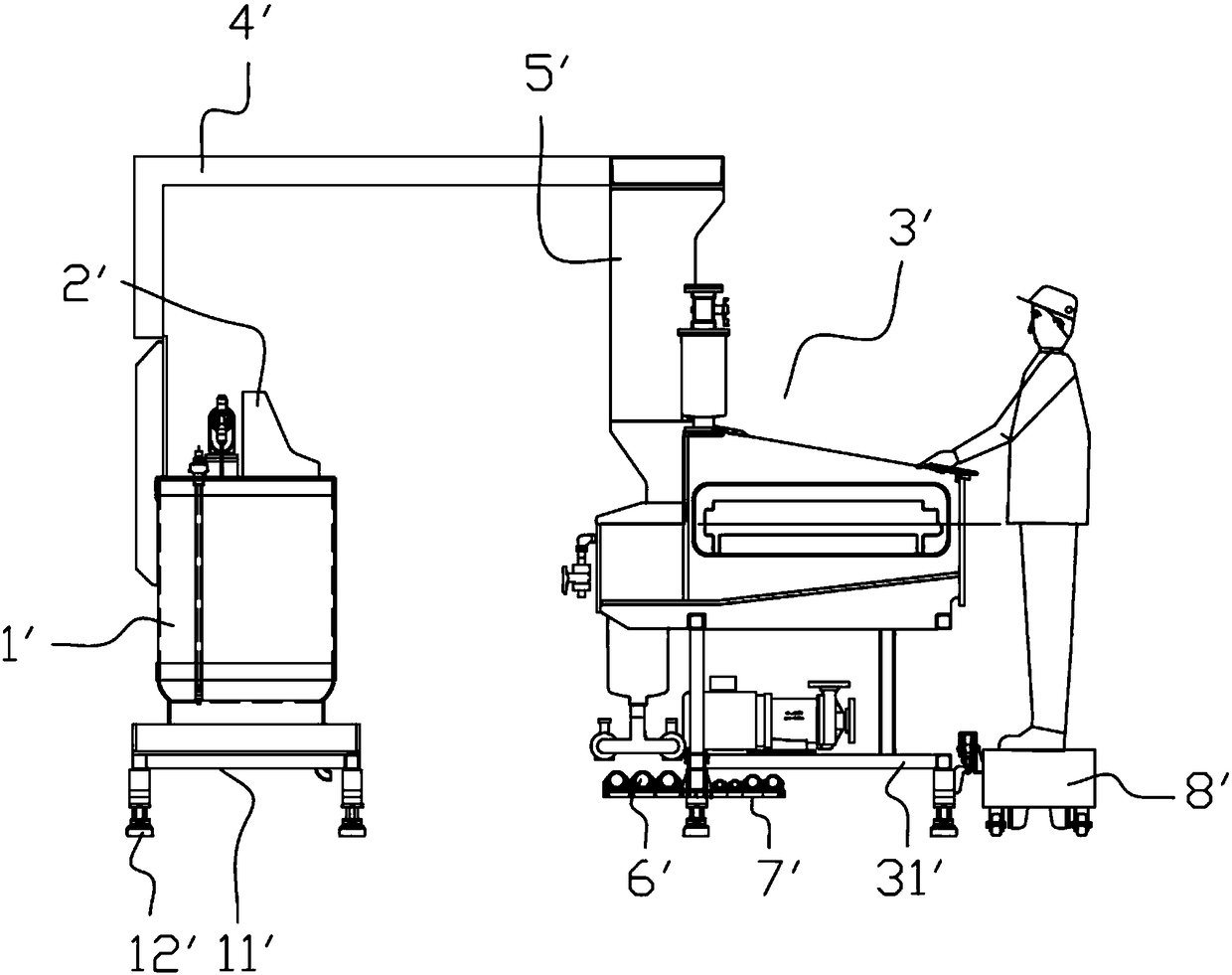

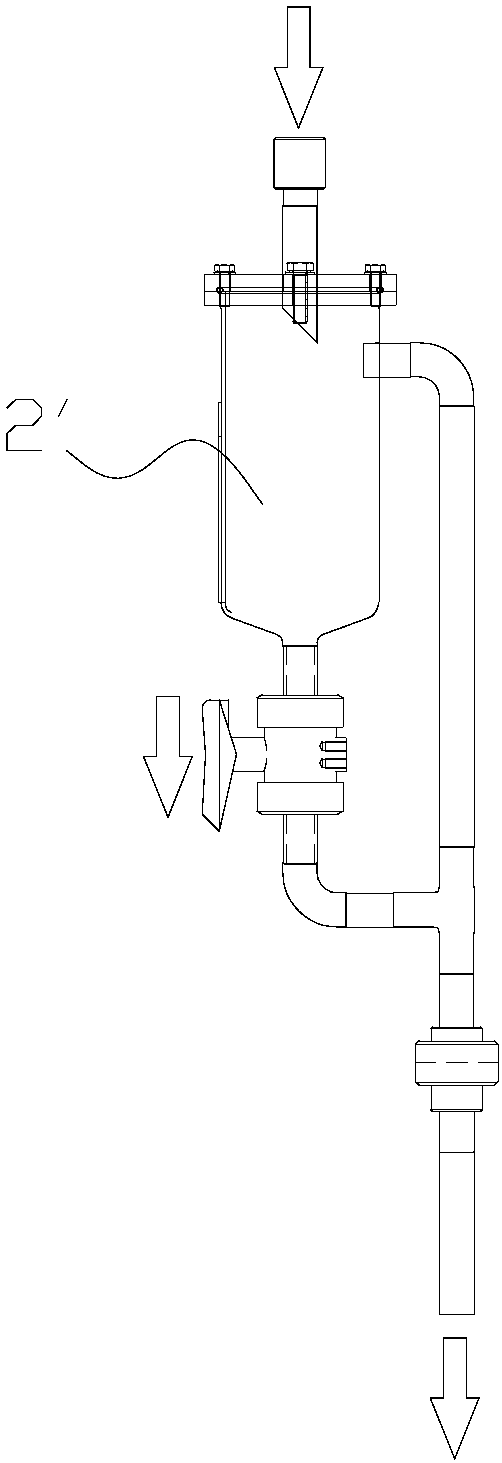

[0066] see Figure 5-Figure 6 Shown is a schematic structural diagram of the improved intensive wet process equipment of this embodiment. It includes a main equipment unit and a medicine adding tank unit, the main equipment unit includes a plurality of main equipment 1 arranged side by side, and the medicine adding tank unit includes a plurality of medicine adding tanks 2 arranged side by side.

[0067] The main device 1 includes: a device main body 10 and a support mechanism 11, at least used to support the device main body 10. The support mechanism 11 includes a pump support tube 11a, a pipeline support tube 11b, an adding tank support tube 11c and Adjustment machine feet 11d at the bottom.

[0068] The height between the support mechanism 11 and the ground is set so that the interior of the support mechanism 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com