printed wiring board

A technology of printed wiring boards and signal lines, which is applied in the fields of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problems of insufficient transmission characteristics and high dielectric constant, and achieve the effect of high transmission characteristics and high wiring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

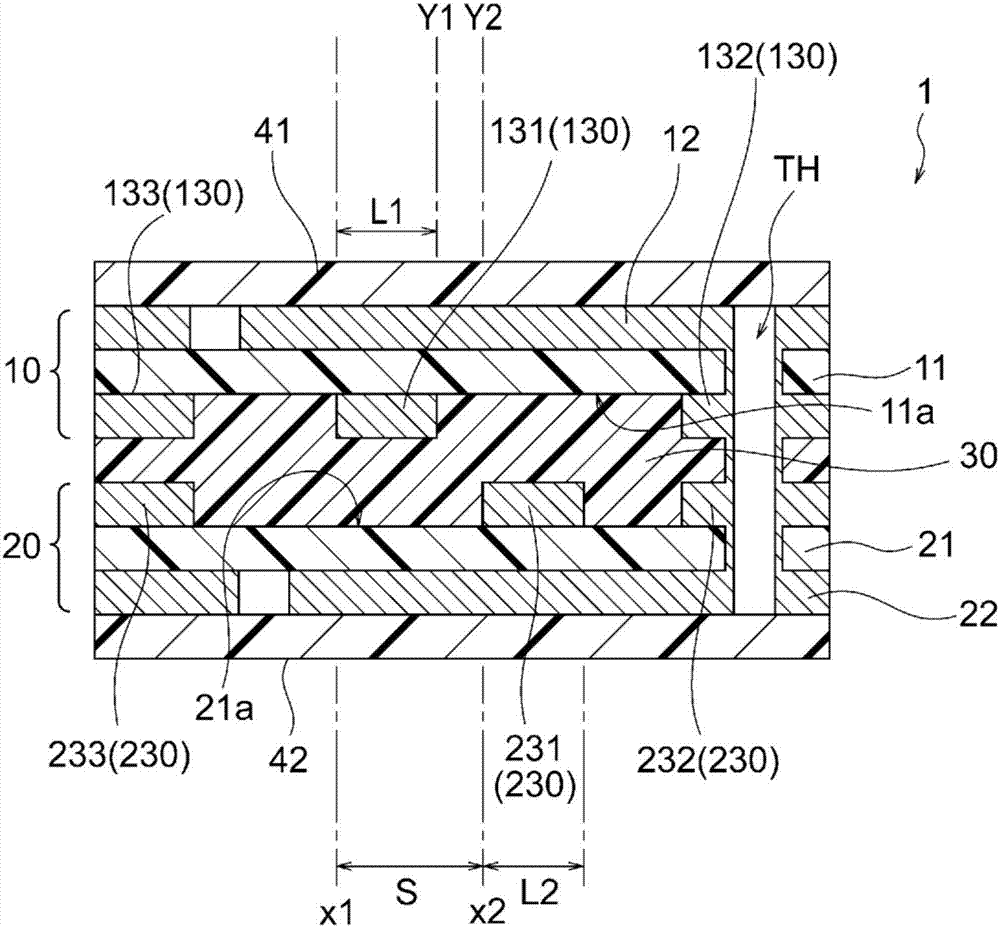

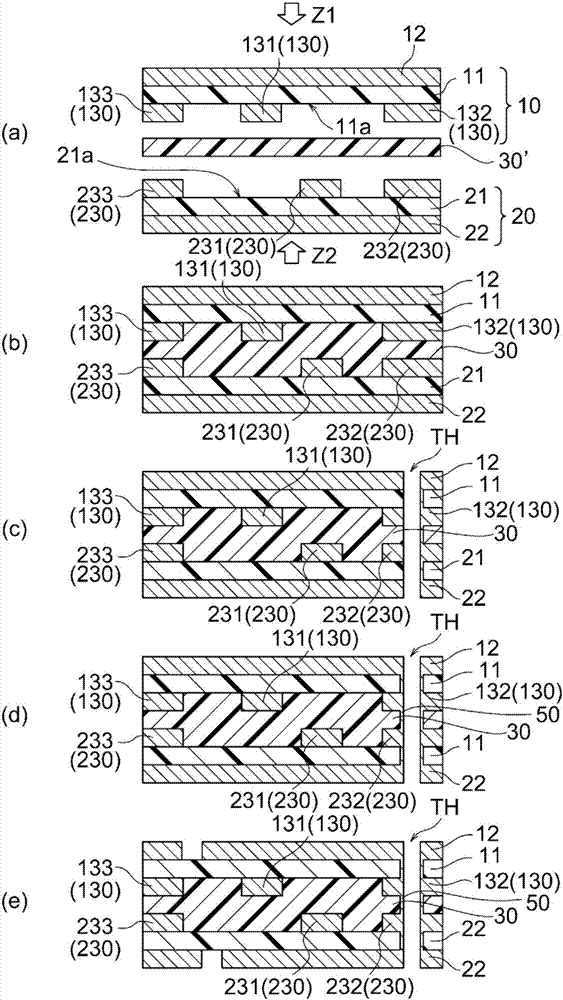

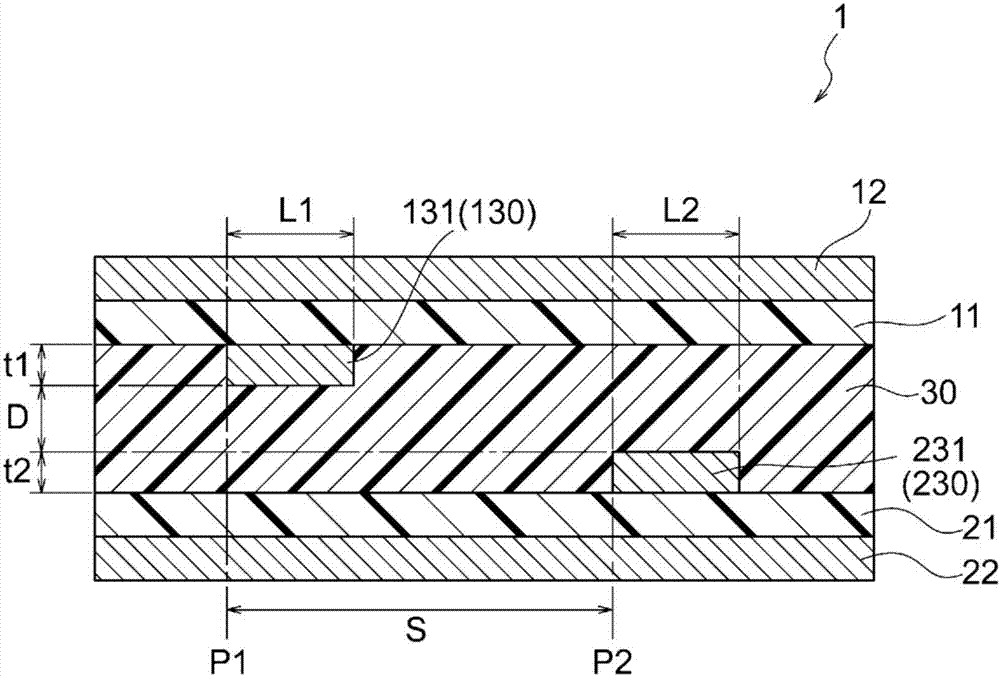

[0033] Hereinafter, an embodiment of the present invention will be described based on the drawings. In this embodiment, an example in which the printed wiring board 1 of the present invention is applied to a transmission line between circuits, between circuits and devices, or between connecting devices within a device will be described. The printed wiring board 1 of this embodiment is suitable for high-speed signal transmission, and can perform transmission based on various standards such as LVDS, MIPI, HDMI (registered trademark), and USB.

[0034] figure 1 It is a cross-sectional view of the printed wiring board 1 of this embodiment. Such as figure 1 As shown, the printed wiring board 1 of this embodiment has a laminated structure in which a first base material 10 and a second base material 20 are laminated. in figure 1 In the illustrated example, the first base material 10 is laminated on the upper side of the second base material 20, but it may be reversed.

[0035] The first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com