Curd direct-heating flavored pizza cheese and manufacturing method thereof

A technology of pizza cheese and its production method, which is applied in the food field to achieve the effects of shortening the process flow, simplifying the process and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

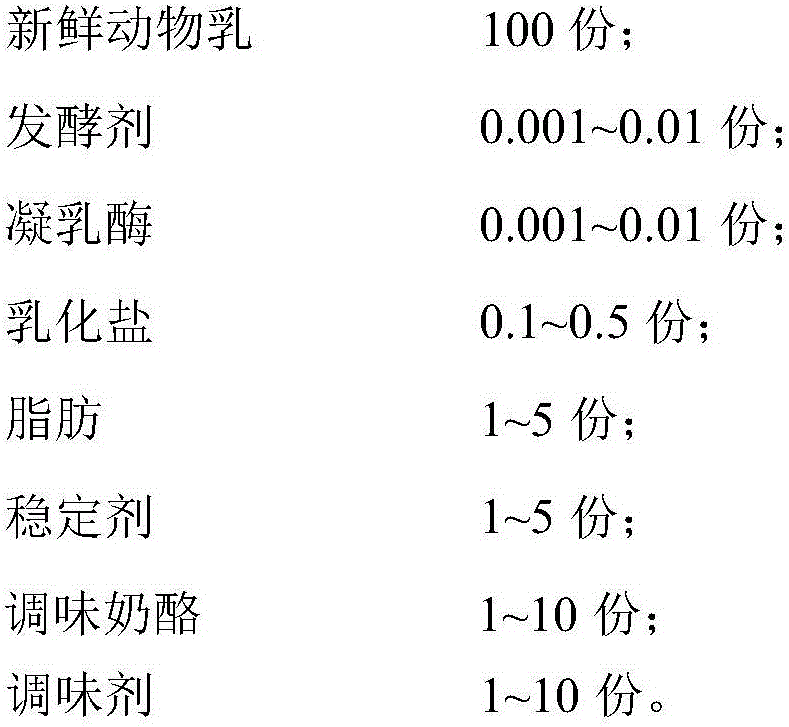

[0038] A kind of curd direct heating seasoning pizza cheese, its composition and weight are as follows:

[0039]

[0040] The method for making the above-mentioned curd directly heating seasoned pizza cheese, the steps are as follows:

[0041] (1) Using fresh animal milk as raw material, adding starter and rennet to prepare fresh curd;

[0042] To prepare fresh curd, follow these steps:

[0043] a. Remove impurities and foam from fresh milk to form raw milk;

[0044] b. Pasteurize the raw milk: sterilize for 30 minutes at a temperature of 63°C to 65°C; or sterilize for 15 seconds at a temperature of 72°C to 75°C;

[0045] cFermentation and curd: adjust the temperature of the sterilized milk to 36°C-38°C, add Lactobacillus bulgaricus; the fermentation time is 60-120 minutes; when the pH of the raw milk reaches 6.1-6.3, add calf rennet; After stirring evenly for 2 to 3 minutes, the raw milk was allowed to stand for coagulation. At this time, the temperature of the raw milk...

Embodiment 2

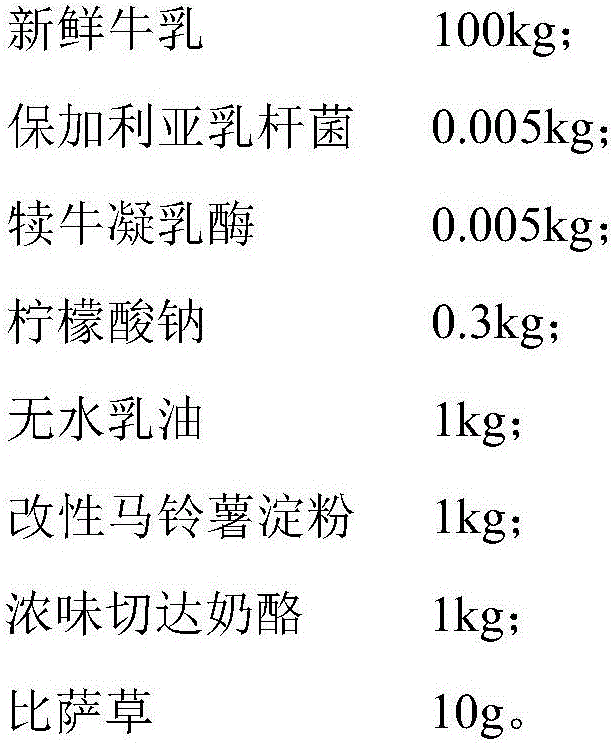

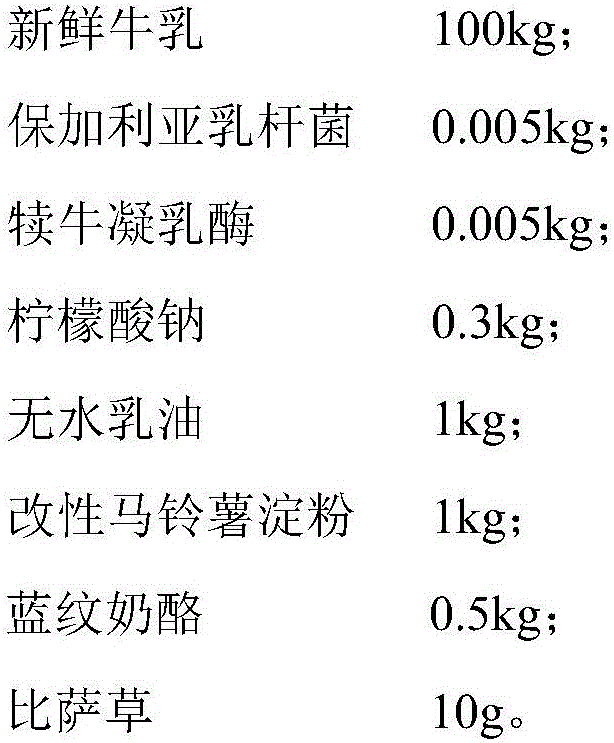

[0051] A kind of curd direct heating seasoning pizza cheese, its composition and weight are as follows:

[0052]

[0053]The method for making the above-mentioned curd directly heating seasoned pizza cheese, the steps are as follows:

[0054] (1) Using fresh milk as raw material, adding starter and rennet to prepare fresh curd;

[0055] (2) Add anhydrous EC, modified potato starch, sodium citrate, blue cheese and pizza grass to the fresh curd, stir and heat to 70-75°C, and keep for 3-5 minutes;

[0056] (3) Fill it into a container, cool it down to below 10°C to get pizza cheese, and store it at this temperature;

[0057] Wherein, the preparation method of described fresh curd comprises the steps:

[0058] (1) Milk cleaning: Use a centrifugal milk cleaning machine to remove impurities and foam in fresh animal milk to form raw milk;

[0059] (2) Pasteurization: sterilize raw milk at 63°C to 65°C for 30 minutes; or at 73°C for 15 seconds;

[0060] (3) Fermentation and cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com