Preparation method and application of visible light and ozone cooperating catalyst for catalytically degrading organic acid

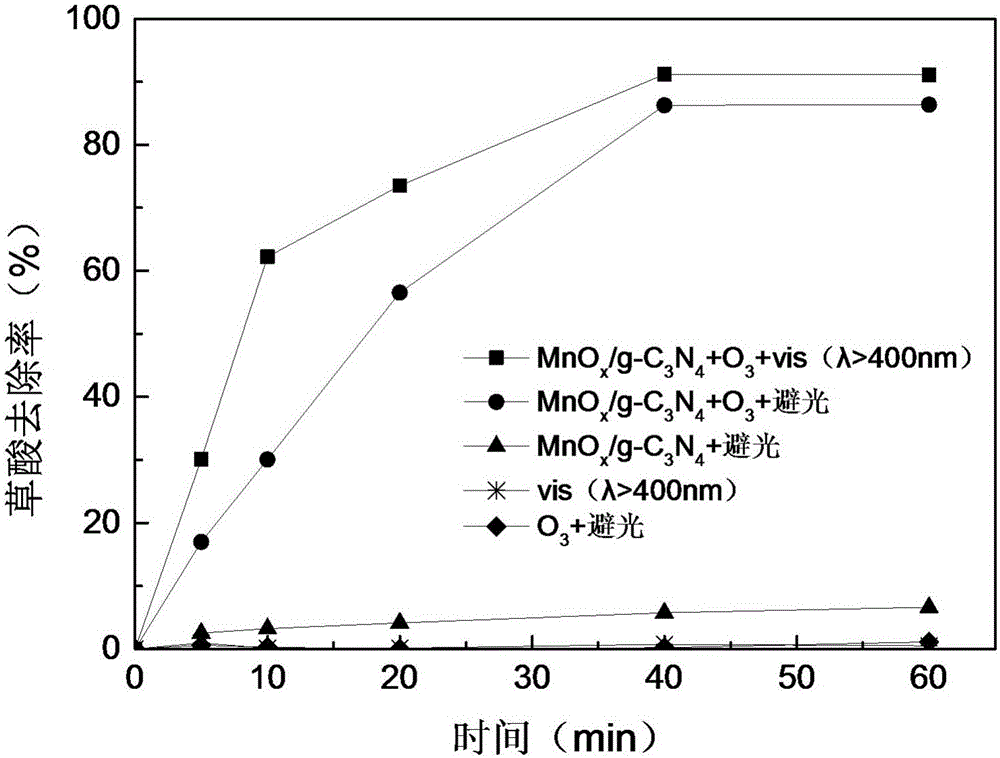

An organic acid catalyst and ozone catalysis technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, oxidized water/sewage treatment, etc., to achieve high catalytic degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

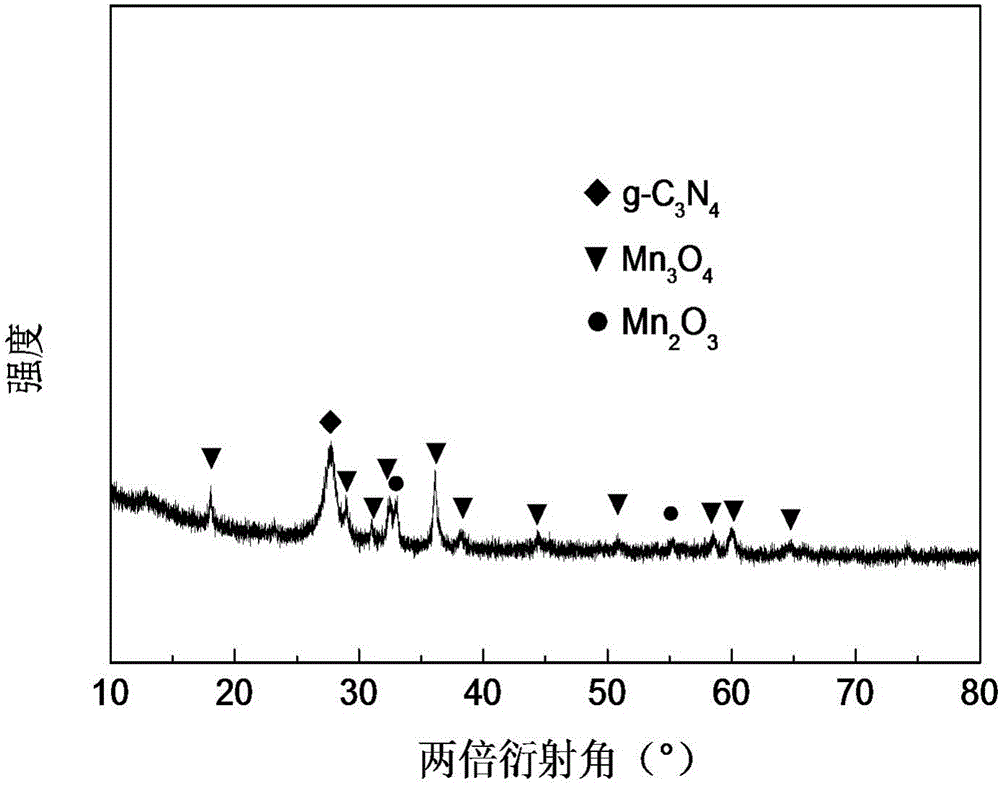

[0026] Example 1 Preparation of MnO x / g -C 3 N 4 catalyst

[0027] The preparation method of the catalyst for the visible light synergistic ozone catalytic degradation organic acid provided in this embodiment comprises the following steps:

[0028] Step 1, the manganese acetate (III) dihydrate (C 6 h 13 MnO 8 ) and dissolved in 40ml of ultrapure water, after stirring for 5min, 4g of melamine was added to obtain a mixed solution.

[0029] Step 2, heating the mixed solution until the water is evaporated to dryness while stirring to obtain the mixture, and putting the mixture into an oven at a temperature of 90° C. to dry to obtain the dried mixture;

[0030] Step 3: Grinding the dried mixture obtained in Step 2, putting it into a crucible and calcining it in a muffle furnace with a temperature of 550°C (rising temperature: 10°C / min) for 4 hours to obtain a calcined mixture;

[0031] Step 4, after grinding the calcined mixture obtained in step 3, sieve under a sieve of 10...

Embodiment 2

[0034] Example 2 Preparation of MnO x / g -C 3 N 4 catalyst

[0035] The preparation method of the visible light synergistic ozone catalytic degradation organic acid catalyst provided in this embodiment comprises the following steps:

[0036] Step 1, the manganese acetate (III) dihydrate (C 6 h 13 MnO 8 ) and dissolved in 32ml of ultrapure water, after stirring for 10min, 2g of melamine was added to obtain a mixed solution.

[0037] Step 2: heating the mixed solution until the water is evaporated to dryness while stirring to obtain a mixture, and drying the mixture in an oven at a temperature of 80° C. to obtain a dried mixture.

[0038] Step 3: Grinding the dried mixture obtained in Step 2, putting it into a crucible and calcining for 3 hours in a muffle furnace at a temperature of 500°C (rising temperature: 10°C / min) to obtain a calcined mixture.

[0039] Step 4, after grinding the calcined mixture obtained in step 3, sieve under a sieve of 150 mesh (Taylor standard siev...

Embodiment 3

[0040] Example 3 Preparation of MnO x / g -C 3 N 4 catalyst

[0041] The preparation method of the visible light synergistic ozone catalytic degradation organic acid catalyst provided in this embodiment comprises the following steps:

[0042] Step 1, the manganese acetate (III) dihydrate (C 6 h 13 MnO 8 ) and dissolved in 36ml of ultrapure water, after stirring for 8min, 3.2g of melamine was added to obtain a mixed solution.

[0043] Step 2: heating the mixed solution until the water is evaporated to dryness while stirring to obtain a mixture, and drying the mixture in an oven at a temperature of 120° C. to obtain a dried mixture.

[0044] Step 3: Grinding the dried mixture obtained in Step 2, putting it into a crucible and calcining for 5 hours in a muffle furnace at a temperature of 600°C (rising temperature: 10°C / min) to obtain a calcined mixture.

[0045] Step 4, after grinding the calcined mixture obtained in step 3, sieve under a sieve of 200 mesh (Taylor standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com