Friction stir welding keyhole filling method

A technology of friction stir welding and keyhole, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of limited weld structure, high equipment requirements, and low mechanical properties of the repaired position, and meet the equipment requirements Low, no metallurgical defects, the effect of eliminating keyholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

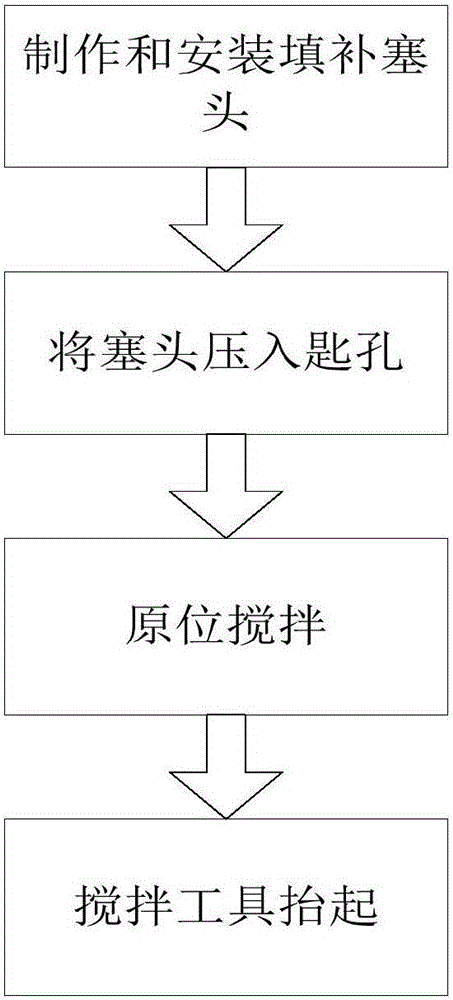

[0016] The friction stir welding keyhole filling method provided by the preferred embodiment of the present invention includes the following steps:

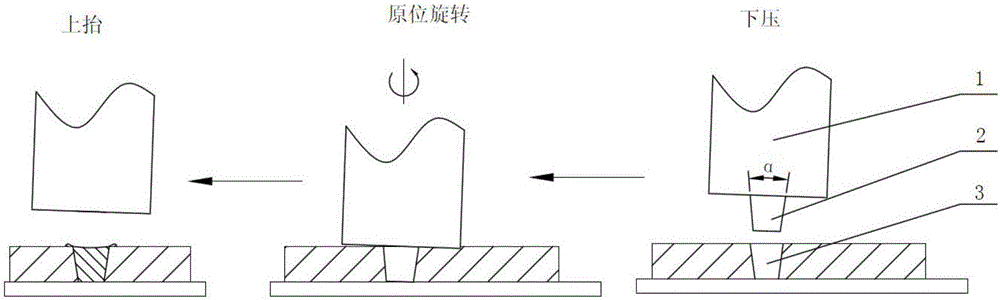

[0017] Step 1. Make and install the filling plug 2. The filling plug 2 is made of the same grade material as the base metal to be repaired or a material of a different grade but with a higher strength grade. The shape is frustum-shaped, and the cone angle α should not be greater than 30°; 1 on.

[0018] Step 2: Start the welding machine, and press the plug 2 into the welding keyhole 3 . During the pressing down process of the plug head 2, the pressing speed should be 0.25%~0.5% of the rotation speed of the stirring tool;

[0019] Step 3, stirring in situ. Stir in situ according to a certain parameter, and the stirring parameter should be appropriately higher than the original friction stir welding par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com