Composite car energy absorption part and machining method thereof

A technology of energy absorption and composite materials, which is applied in vehicle parts, chemical instruments and methods, applications, etc., can solve the problems of high price of composite materials and restrictions on the promotion of energy absorption components of composite materials, and achieve reduced production costs, light weight, and relatively low cost. The effect of high energy absorption value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

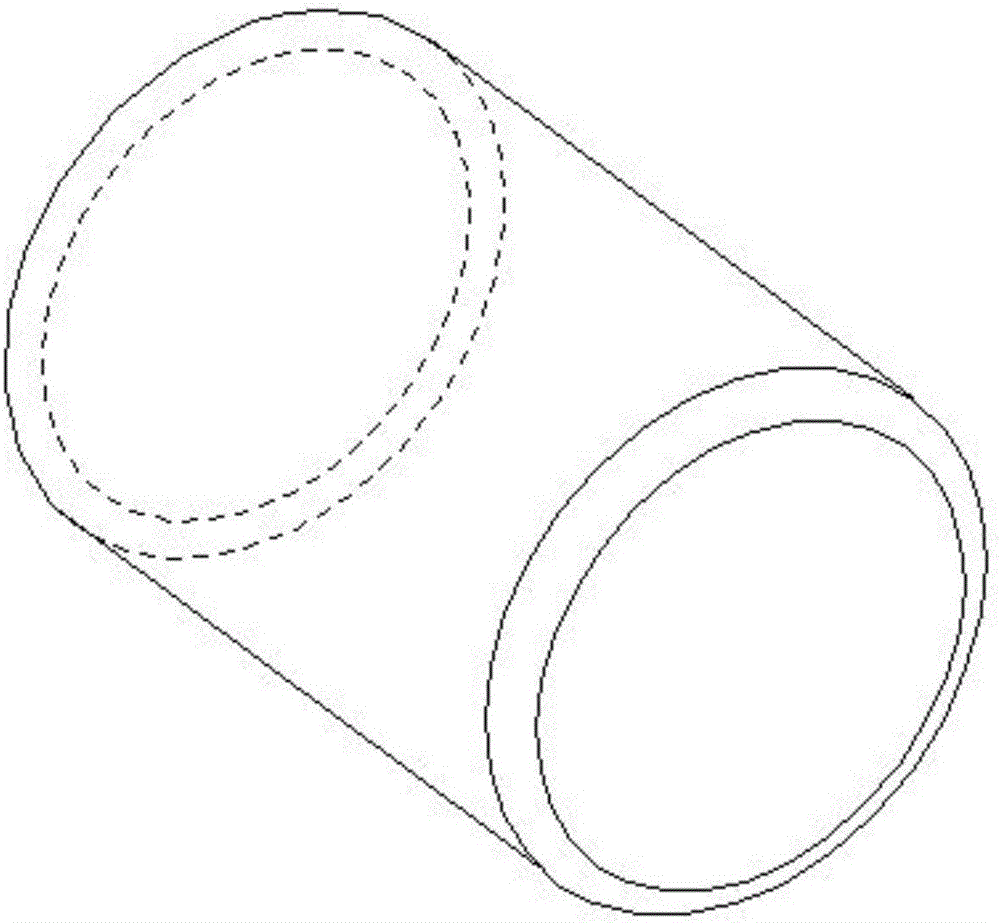

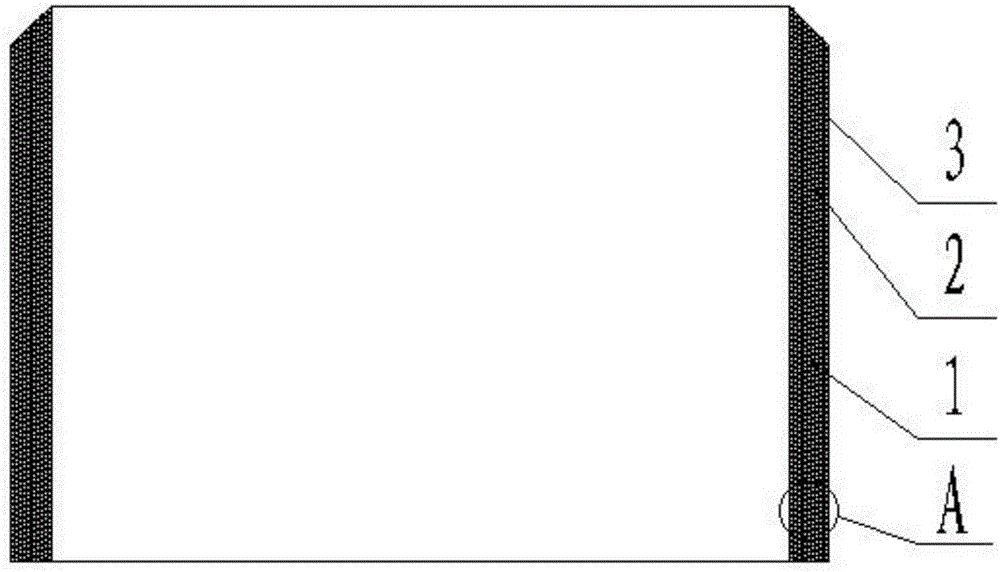

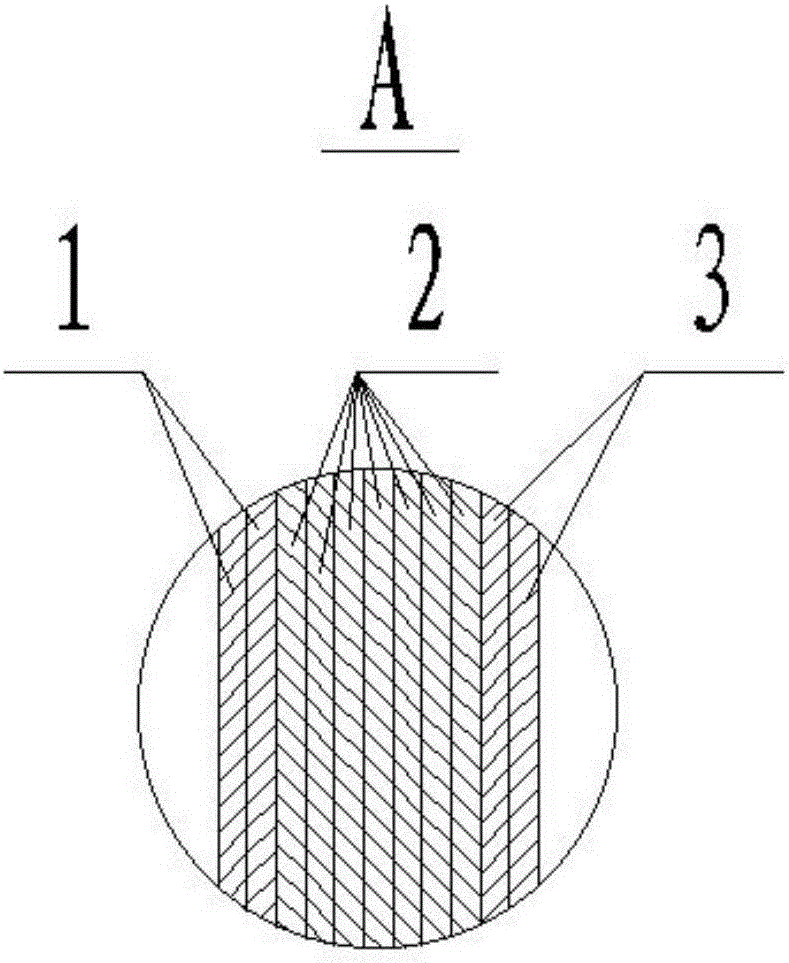

[0033] Embodiment 1: as Figure 1-3 As shown, this embodiment discloses an energy absorbing component for vehicles made of composite material, which is in the shape of a circular tube with a wall thickness of 1.8±0.1 mm and an inner diameter of the tube of 34 mm. It includes two first carbon fiber layers 1 , seven glass fiber layers 2 and two second carbon fiber layers 3 wound sequentially from inside to outside. The ratio of the volume of the glass fiber layer 2 to the sum of the volumes of the first carbon fiber layer 1 and the second carbon fiber layer 3 is about 7:4. One end of the tubular structure is provided with a 45° chamfer, and the other end is flat.

[0034] The processing method of the composite material vehicle energy absorbing part of the present embodiment comprises the following steps:

[0035] Step 1: Cut the carbon fiber fabric prepreg and glass fiber fabric prepreg to preset size;

[0036] Step 2: Wind the carbon fiber fabric prepreg onto the steel mandr...

Embodiment 2

[0051] Example 2, as a further improvement to Example 1, the glass fiber layer 2 is replaced by a basalt fiber layer, the curing temperature is 120°C, and the curing time is 2 hours; when the temperature drops to 40°C, demoulding treatment is performed. The specific energy absorption value of this embodiment is not lower than 110kJ / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com