Cap arranging device

A technology for unscrambling caps and bottle caps, which is applied in the field of cap unscrambling devices for output after sorting bottle caps, which can solve the problems of large compressed air consumption, increased accumulation of equipment damage, and loud noise, so as to reduce gas consumption and noise impact, The effect of improving work efficiency and simplifying equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

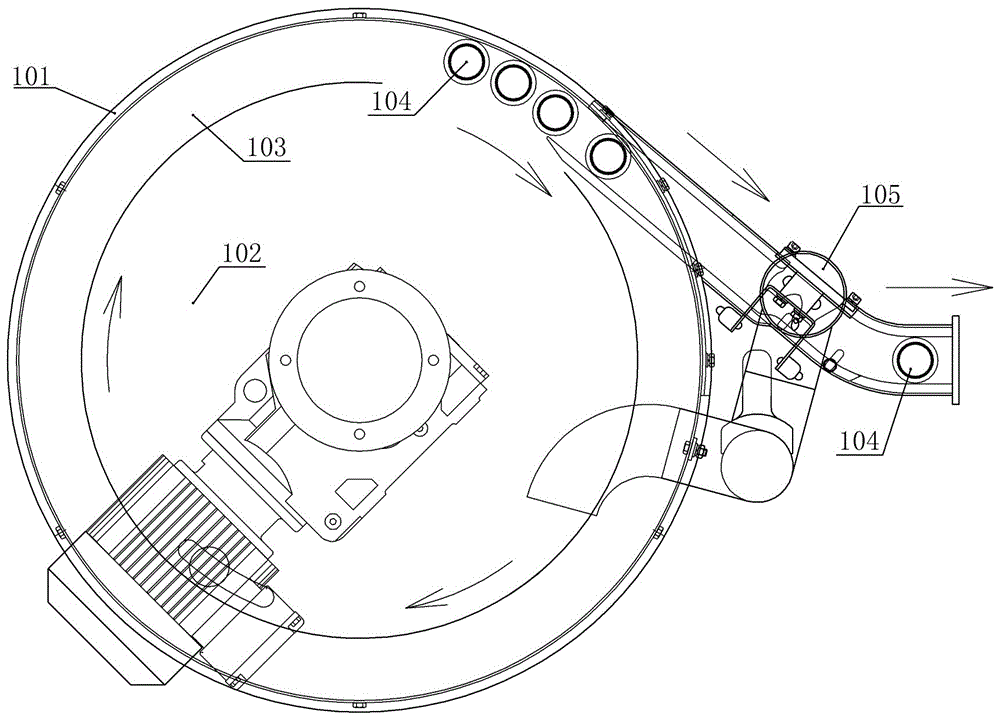

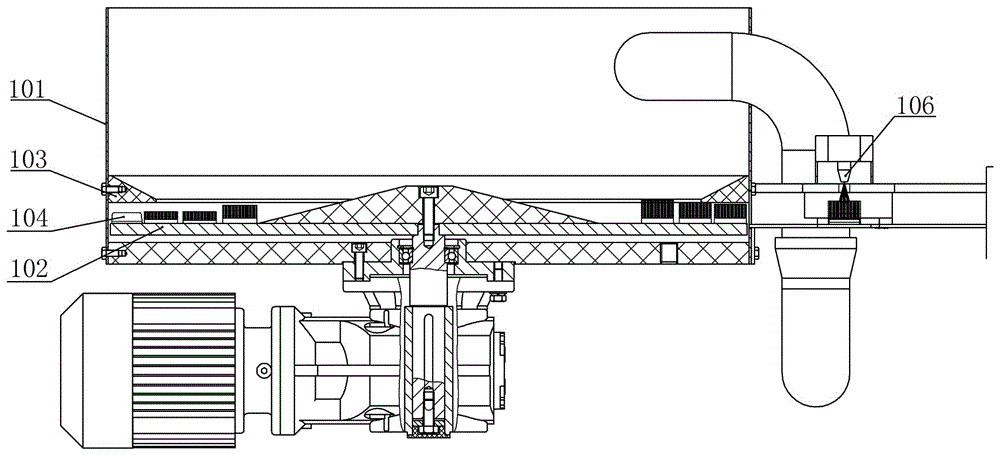

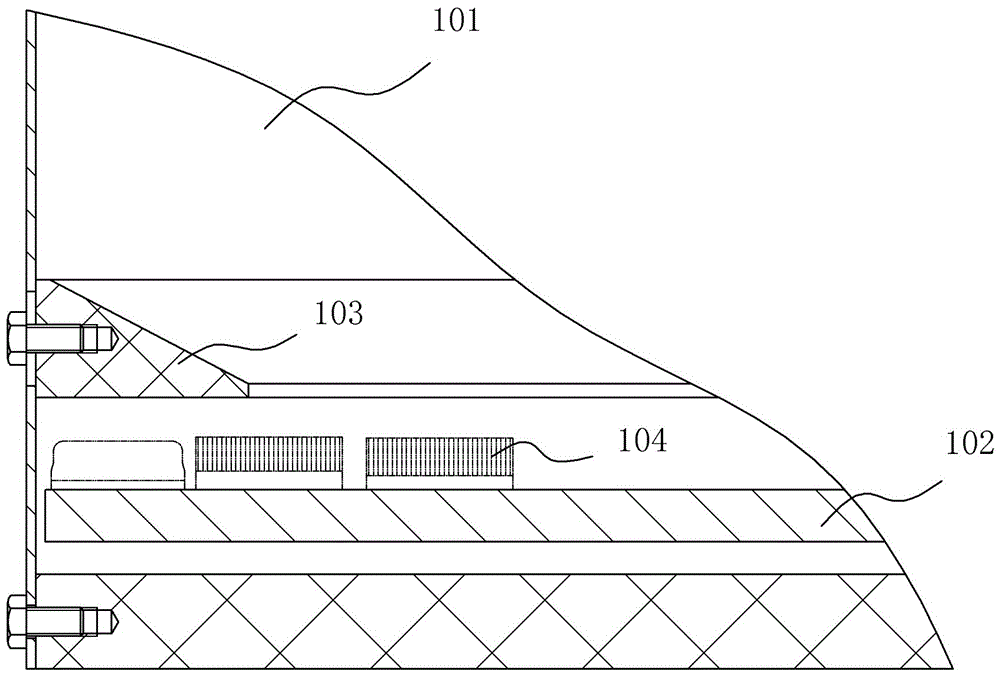

[0017] Such as Figure 6-8 As shown, a cap sorting device includes a cylinder 1, a rotating turntable 2, an annular retaining ring 3 and an output channel 4 for outputting bottle caps. The turntable is installed in the cylinder, and the annular retaining ring is installed above the turntable. There is an outlet connected to the output channel along the tangential direction on the cylinder. A guide block 5 for screening and guiding the bottle cap is installed at the outlet. The guide block is installed above the turntable. The groove 51 that matches the boss 202 of the boss, specifically the groove matches the boss of the bottle cap with the boss upward, and the height of the bottom of the guide block is between the body of the bottle cap 201 and the top surface of the boss, and the guide block The side facing away from the outlet of the cylinder is a guide slope 52 directed from the inner wall of the cylinder to the middle of the cylinder and inclined towards the advancing dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com