Overturning bottle unscrambler

A bottle unscrambler and bottle unscrambler technology, applied in the field of bottle unscrambler, can solve the problems of inconvenient operation, cumbersome operation, complicated structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

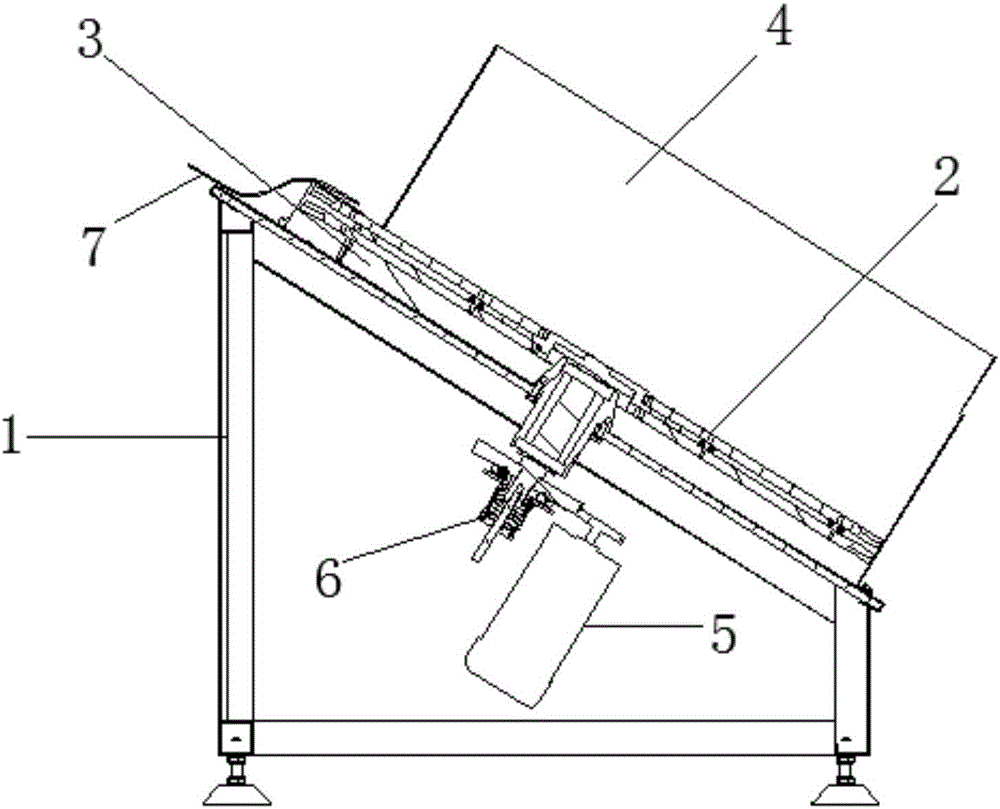

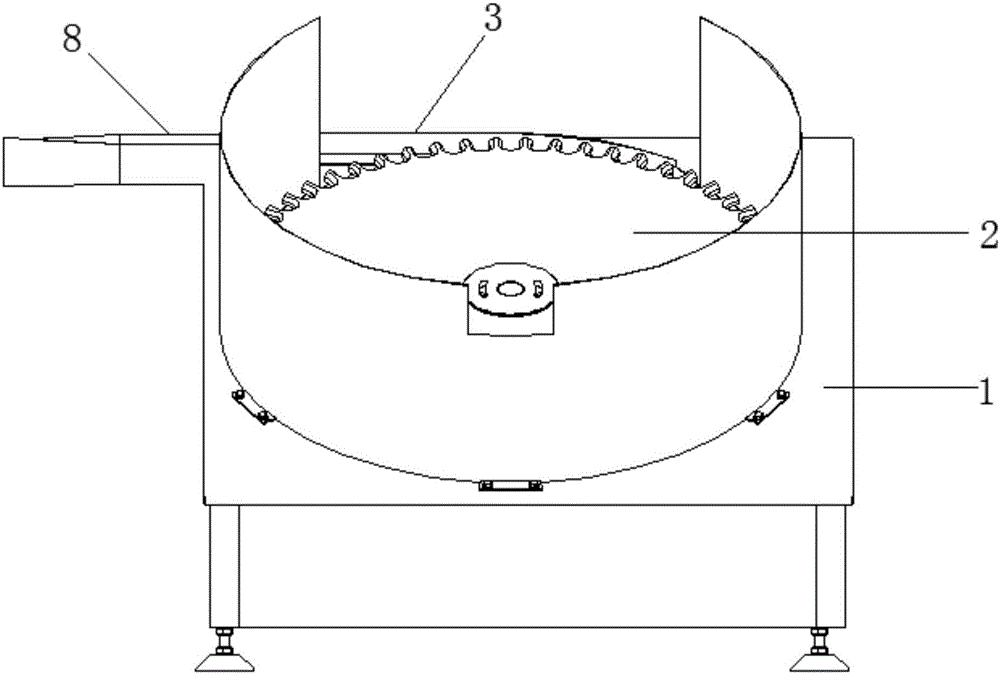

[0014] Such as figure 1 and figure 2 As shown, the flipping bottle unscrambler of the present invention includes a frame 1, the frame 1 is provided with an inclined surface, and the inclined surface of the frame 1 is provided with an open storage tank 4. The bottle unscrambling turntable 2 is arranged inside the storage barrel 4, and the bottle unscrambling turntable 2 is evenly provided with the bottle arrangement teeth on the outer circumference, so that it can ensure that the bottles put into the material storage barrel 4 will automatically fall into the bottle unscrambling turntable 2. The outer edge is equally divided into the bottle unscrambling teeth. The bottle unscrambling teeth are specially designed according to the bottle, so that the bottle can smoothly enter the adjacent teeth of the bottle unscrambling turntable. The bottle unscrambling turntable 2 is connected to the drive motor 5 through transmission;

[0015] Further, in order to ensure a safer action of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com