Method for preparing coal-water slurry using fractal grading technology and prepared coal-water slurry

A technology of coal-water slurry and slurry, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of low coal-water slurry accumulation efficiency, low concentration of coal-water slurry, and poor stability, so as to expand the scope of application, High concentration and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing coal-water slurry by using Shenfu coal as coal raw material. Shenfu coal is a kind of common coal in Inner Mongolia area. The analytical water is 4.9%, the total water is 13%, and the ash content is 13.9%.

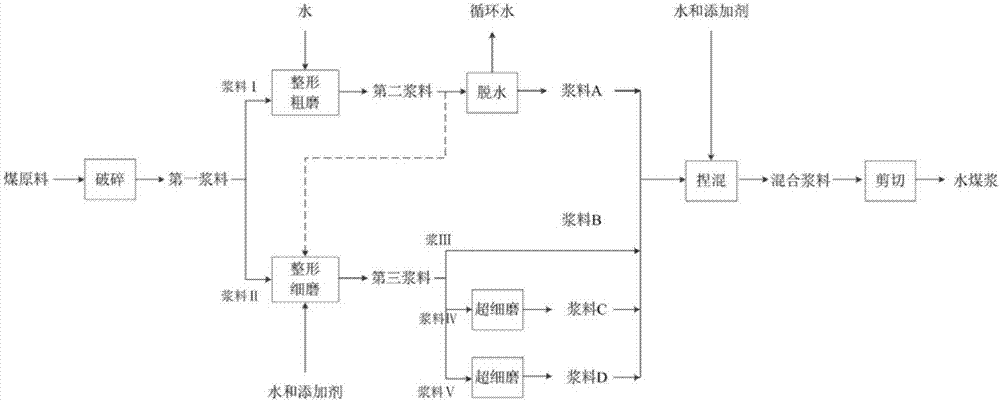

[0053] The method comprises the steps of:

[0054] (1) crushing the coal raw material to obtain the first slurry with a particle size≤13mm;

[0055] (2) Divide the first slurry into slurry I and slurry II, the pulverized coal in the slurry I accounts for 75wt% of the quality of the pulverized coal in the first slurry, and the pulverized coal in the slurry II accounts for 75% by weight of the first slurry 25wt% of the pulverized coal mass in the material, the slurry I and water are subjected to shaping wet rough grinding with a mass ratio of 7:3 to obtain the second slurry with a pulverized coal particle size of 2000 μm;

[0056] (3) Return a part of the second slurry as slurry I ' to the raw material of the shaping wet ball mill (the coal pow...

Embodiment 2

[0065] The invention discloses a method for preparing coal-water slurry from Xinjiang Hongshan coal as coal raw material. Hongshan coal is a common coal in Xinjiang area, the total water content is 24%, and the ash content is 14%.

[0066] The method comprises the steps of:

[0067] (1) crushing the coal raw material to obtain the first slurry with a particle size≤13mm;

[0068] (2) Divide the first slurry into slurry I and slurry II, the pulverized coal in the slurry I accounts for 80wt% of the quality of the pulverized coal in the first slurry, and the pulverized coal in the slurry II accounts for 80% by weight of the first slurry 20wt% of the pulverized coal mass in the material, the slurry I and water are subjected to shaping wet rough grinding in a mass ratio of 8:2 to obtain the second slurry with a pulverized coal particle size of 1000 μm;

[0069] (3) mixing slurry II, water and additives in a mass ratio of 70:30:0.1 for shaping wet fine grinding to obtain a third slu...

Embodiment 3

[0078] The invention discloses a method for preparing coal-water slurry from lignite as coal raw material. Lignite is a common coal in Inner Mongolia. The analyzed water is 20.8%, the total water is 34.5%, and the ash content is 8.5%.

[0079] The method comprises the steps of:

[0080] (1) crushing the coal raw material to obtain the first slurry with a particle size≤13mm;

[0081] (2) Divide the first slurry into slurry I and slurry II, the pulverized coal in the slurry I accounts for 85wt% of the quality of the pulverized coal in the first slurry, and the pulverized coal in the slurry II accounts for 85% by weight of the first slurry 15wt% of the mass of coal powder in the material, the slurry I and water are subjected to shaping wet rough grinding according to the mass ratio of 7:3 to obtain the second slurry with a particle size of coal powder of 600 μm;

[0082] (3) A part of the second slurry is added as slurry I' back to the raw material of the shaping wet ball mill (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com