Thick X42 pipeline steel and production method thereof

A pipeline steel, thick gauge technology, applied to thick gauge X42 pipeline steel and its production field, can solve the problems of low drop weight performance qualification rate, narrow coiling temperature control range, large coiling temperature fluctuation, etc., and achieve production control. Low difficulty, wide coiling temperature range and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

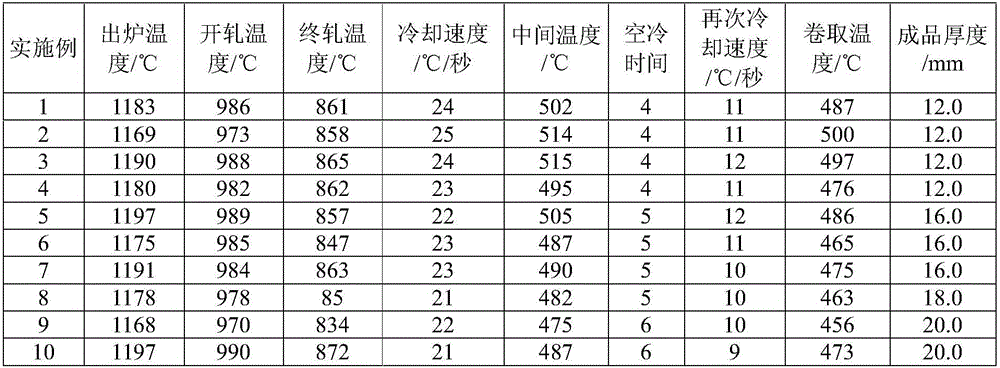

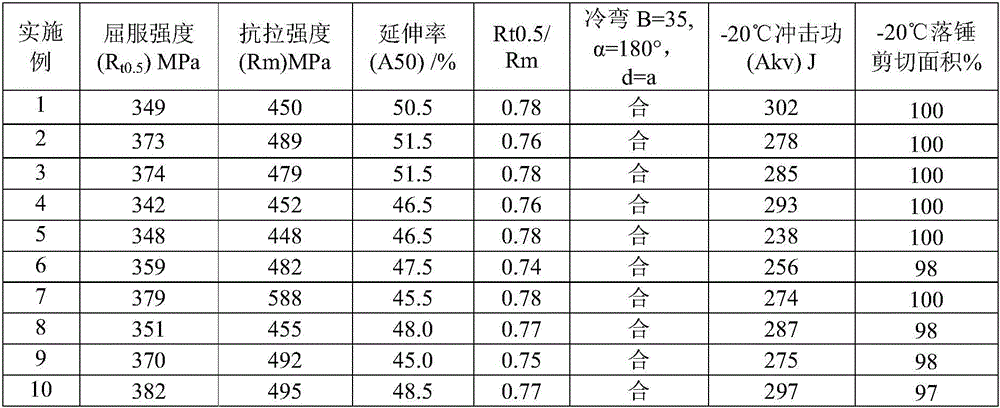

Examples

Embodiment Construction

[0019] The thick gauge X42 pipeline steel of the present invention has the following chemical composition by weight percentage: C: 0.03%-0.07%, Si: 0.10%-0.30%, Mn: 0.70%-1.00%, P: ≤0.020%, S: ≤0.010%, Nb: 0.015%-0.030%, Ti: 0.008%-0.019%, Cr: 0.15%-0.30%, and the rest are Fe and unavoidable impurities. The invention adopts ultra-low carbon niobium microalloying, adds a certain amount of Cr, does not need to add expensive Mo, Ni and other elements, has the advantages of low production cost, high production efficiency, simple process control, strong operability and high performance pass rate features.

[0020] In order to further improve the mechanical properties of thick gauge X42 pipeline steel, especially the drop hammer performance, its chemical composition has been further optimized, and its chemical composition is composed of: C: 0.03%-0.06%, Si: 0.15%-0.25 %, Mn: 0.75%-0.90%, P: ≤0.018%, S: ≤0.008%, Nb: 0.018%-0.025%, Ti: 0.010%-0.017%, Cr: 0.18%-0.22%, and the rest are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com