Vanadium-containing automobile transmission shaft steel and production method thereof

A production method and transmission shaft technology, applied in the metallurgical field, can solve the problems of poor toughness, plasticity and weldability of steel, and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

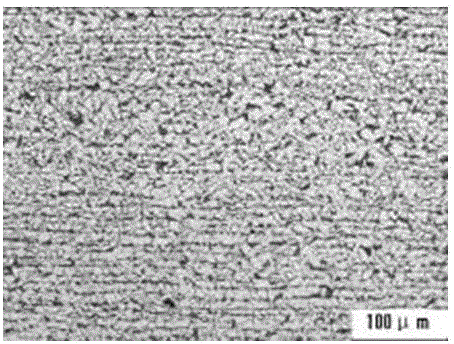

[0040] With a thickness of 2mm and a width of 1250mm, the chemical composition and weight percentage of vanadium-containing steel plates for automobile transmission shafts are: C: 0.08%, Si: 0.10%, Mn: 0.82%, P: 0.010%, S: 0.002%, V: 0.040% , Ti: 0.020%, Als: 0.015%, and the balance is Fe and unavoidable impurity elements. The microstructure of vanadium-containing automobile transmission shaft steel plate is ferrite plus pearlite, and pearlite accounts for about 8%.

[0041] Production method: 1) Smelting molten steel according to the above-mentioned composition, LF refining of molten steel, and continuous casting of slab to obtain slab; 2) Heating the slab to 1180°C, descaling with high-pressure water, rough rolling, and coiling in a hot coil box , finish rolling, and controlled cooling to obtain hot-rolled coils.

[0042] Among them, there are 5 passes of rough rolling, the outlet temperature is 1020°C; the finish rolling outlet temperature is 820°C, the laminar cooling rat...

Embodiment 2

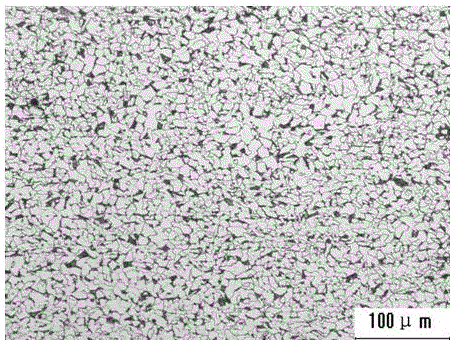

[0044] Thickness 2.5mm, width 1250mm, chemical composition and weight percentage of vanadium-containing automobile drive shaft steel plate are: C: 0.09%, Si: 0.12%, Mn: 1.13%, P: 0.012%, S: 0.0025%, V: 0.045% , Ti: 0.022%, Als: 0.025%, and the balance is Fe and unavoidable impurity elements. The microstructure of vanadium-containing automobile transmission shaft steel plate is ferrite plus pearlite, and pearlite accounts for about 9%.

[0045] Production method: 1) Smelting molten steel according to the above-mentioned composition, LF refining of molten steel, and continuous casting of slab to obtain slab; 2) Heating the slab to 1200°C, descaling with high-pressure water, rough rolling, and coiling in a hot coil box , finish rolling, controlled rolling and cooling to obtain hot-rolled coils.

[0046] Among them, there are 5 passes of rough rolling, the exit temperature is 1040°C; the finish rolling exit temperature is 840°C, the laminar cooling rate is 23°C / min, and the coili...

Embodiment 3

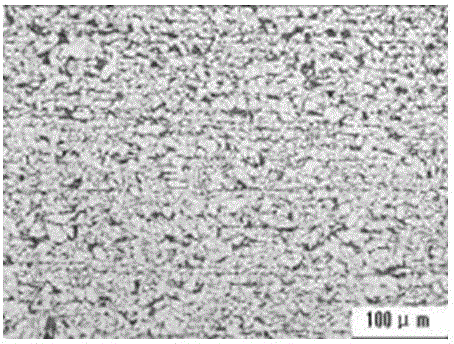

[0048] Thickness 3mm, width 1250mm, chemical composition and weight percentage of vanadium-containing automobile transmission shaft steel plate are: C: 0.10%, Si: 0.15%, Mn: 1.25%, P: 0.014%, S: 0.010%, V: 0.050%, Ti: 0.025%, Als: 0.030%, and the balance is Fe and unavoidable impurity elements. The microstructure of vanadium-containing automobile transmission shaft steel plate is ferrite plus pearlite, and pearlite accounts for about 10%.

[0049] Production method: 1) Smelt molten steel according to the above-mentioned composition, LF refining of molten steel, and slab continuous casting process to obtain slab; 2) Heat the slab to 1240°C, descale with high-pressure water, rough rolling, and coil in a hot coil box , finish rolling, controlled rolling and cooling to obtain hot-rolled coils.

[0050] Among them, there are 5 passes of rough rolling, the outlet temperature is 1060°C; the finish rolling outlet temperature is 850°C, the laminar cooling rate is 24°C / min, and the coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com