Concrete for thermal damage tunnels

A concrete and tunnel technology, applied in the field of building materials, can solve problems such as poor durability, unfavorable project management department organization and management, structural damage, etc., and achieve the effect of reducing thermal stress cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

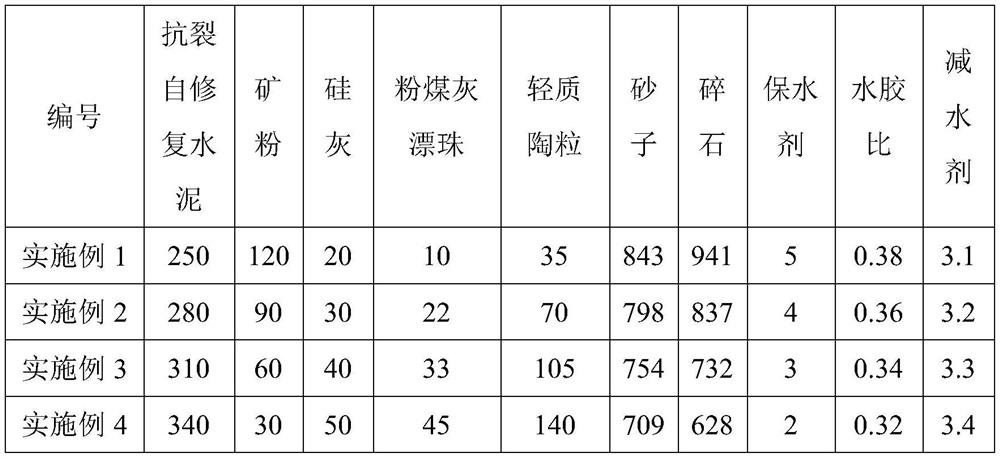

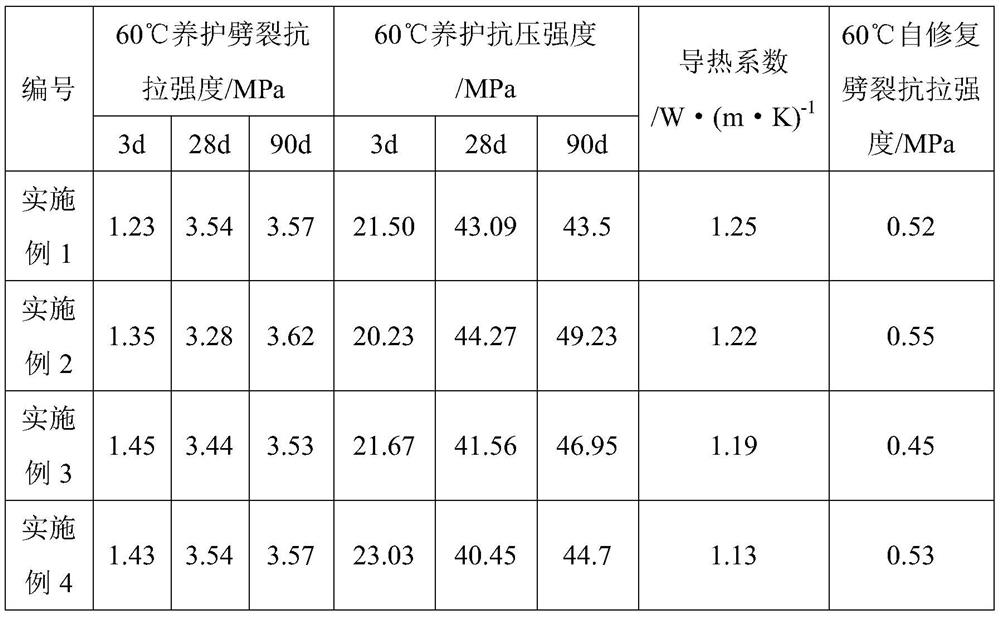

Examples

Embodiment 1

[0048] In this embodiment, the anti-crack self-repairing cement clinker includes 4% square magnesium stone, and 3 ~ 5μm square magnesium content of 0.4%, γ-C 2 The S content is 5%; the anti-crack self-repairing cement, more than 65 μm cement particles account for 15%.

[0049] Fly ash bouncing beads 250kg / m 3 1 to 200 μm of the particle diameter, the static pressure intensity is 80 MPa, the thermal conductivity is 0.1 w / (m · k). Lightweight ceramics accumulation density 300kg / m 3 5 to 10 mm of particle diameter, 1 MPa, and 1 h water absorption of 25%.

[0050] Mine powder specific surface area 425m 2 / kg, 7D active index of 80%, 28D active index 98%, flow rate ratio 101%. Silicon ash than 18M 2 / g, 7D active index (7D fast method) 110%, SIO 2 The content is 95%, the amount of water is more than 118%. The water storage agent is carboxymethylcellulose ether. The water reduction is a high-performance water reducing agent having a polycarboxylic acid, a solid content of 20%, a...

Embodiment 2

[0052] In this embodiment, the anti-crack self-repairing cement clinker includes 5.5% square magnesium stone, and 3 to 5 μm squares content of 0.7%, γ-C 2 The S content is 3%; the anti-crack self-repairing cement, more than 65 μm cement particles account for 20%.

[0053] Fly ash boustic bead 350kg / m 3 The particle diameter is 50 to 150 μm, the static pressure intensity is 90 MPa, and the thermal conductivity is 0.21 w / (m · k). Lightweight ceramics accumulation density 350kg / m 3 The particle diameter is 5 to 10 mm, the cylindrical strength is 1.4 MPa, and the water absorption rate of 1 h is 19%.

[0054] Mine powder specific surface area 400m 2 / kg, 7d active index is 70%, and the 28D active index is 95%, the flow rate is 95%. Silicon ash specific surface area 15m 2 / g, 7D active index (7D fast method) 105%, SIO 2 The content of 85%, the amount of water is 125%. The water retention agent is a phosphate starch. The water reduction is a high-performance water reducing agent ...

Embodiment 3

[0056] In this embodiment, the anti-crack self-repairing cement clinker includes 6.8% square magnesium stone, and 3 to 5 μm square mite content of 0.9%, γ-C 2 The S content is 2%; the anti-crack self-repairing cement, more than 65 μm cement particles account for 23%.

[0057] Fly ash bouncing bead 405kg / m 3 100 to 200 μm of the particle diameter, the static pressure strength 130 MPa, the thermal conductivity is 0.35 w / (m · k). Lightweight ceramics stacking density 420kg / m 3 The particle size is 5 to 10 mm, the cylindrical strength is 1.8 MPa, and the water absorption rate of 1 h is 15%.

[0058] Mine powder specific surface area 427m 2 / kg, 7d active index 75%, 28D active index 98%, and the flow rate is 101%. Silicon ash than 18M 2 / g, 7D active index (7D fast method) 110%, SIO 2 The content is 95%, the amount of water is 121%. The water retention agent is hydroxypropyl cellulose. The water reduction is a high-performance water reducing agent having a polycarboxylic acid, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com