A shaft-mounted brake disc made of aluminum matrix composite material

A technology of aluminum-based composite materials and brake discs, which is applied in the direction of brake discs, brake types, and parts of brakes, can solve problems such as thermal stress cracking, low strength of aluminum-based composite materials, and poor plasticity and toughness. Bolt pre-tightening force, brake service life and safety improvement, and the effect of reducing stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

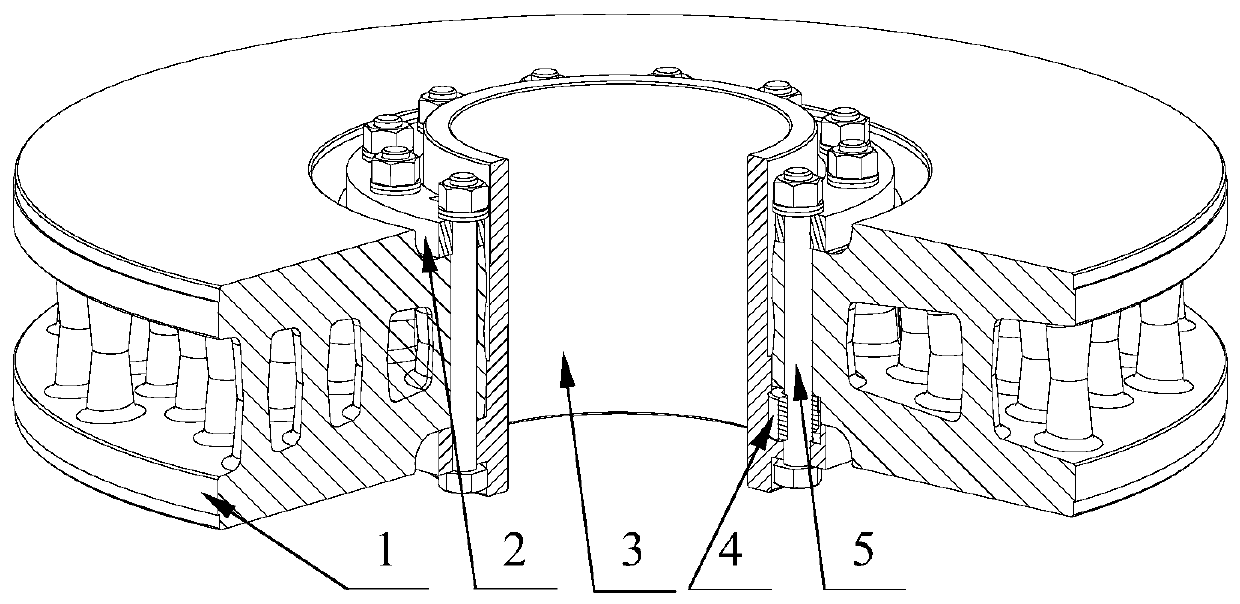

[0020] An aluminum matrix composite shaft mounted brake disc, see figure 1 . The brake disc includes: a disc body 1 , a pressure ring 2 , a disc hub 3 , positioning pins 4 , and a bolt fastening system 5 .

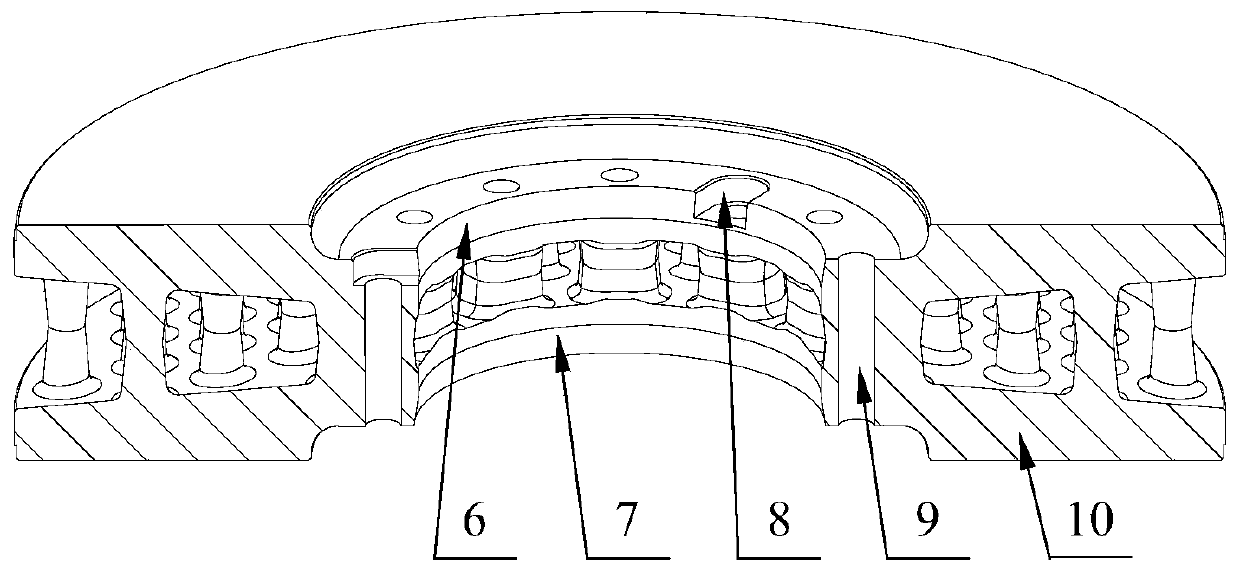

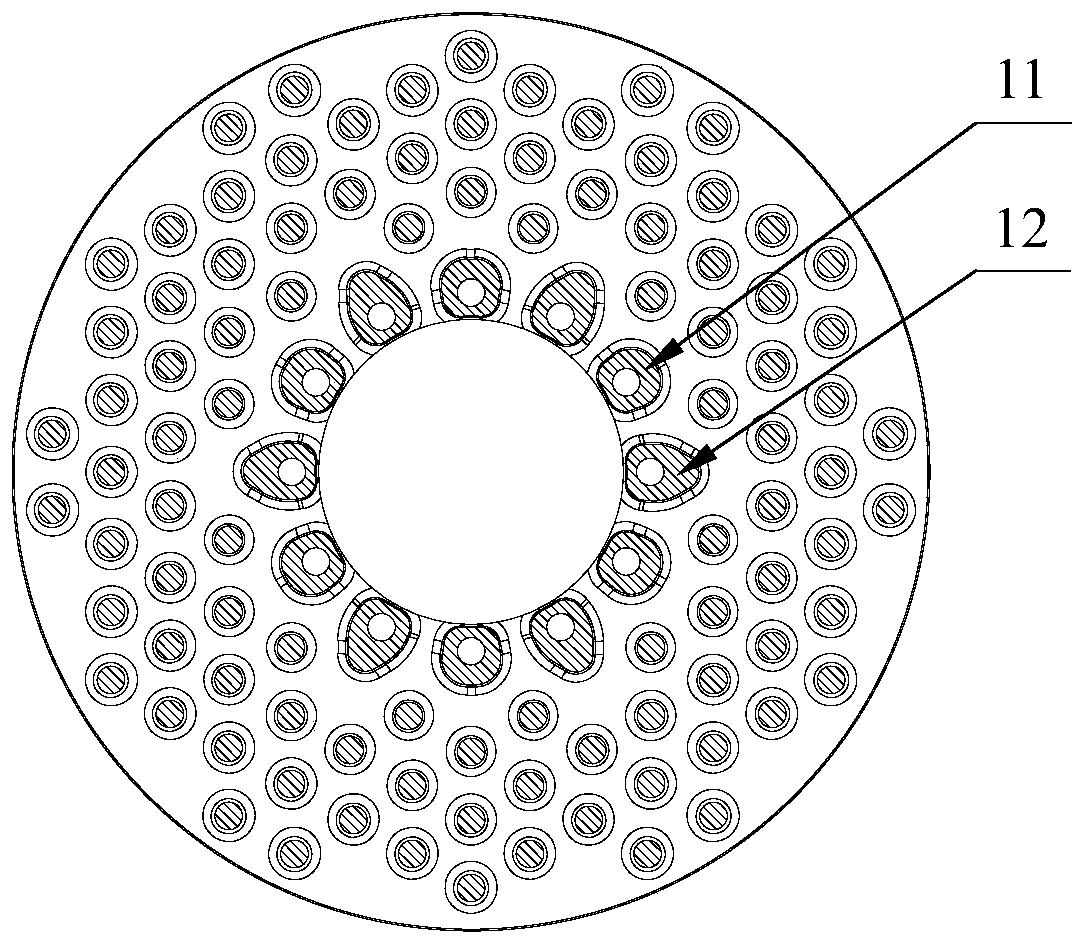

[0021] The disc body 1 has double-layer, ring-shaped flanges, namely flange I6 and flange II7. The ribs are connected, and the heat dissipation ribs are distributed in a regular hexagon. Through holes 9 are opened on flange I 6, flange II 7, connecting column I11 and connecting column II 12, and pin grooves 8 and pin grooves are evenly distributed on flange I 6. The number of 8 is 3, the number of through holes 9 is 12, the thickness of the friction ring 10 of the disc body 1 becomes variable, the larger the radius of the position, the smaller the thickness, see figure 2 and image 3 .

[0022] The disc hub 3 adopts a ring-shaped flange, and 12 mounting holes are evenly distributed on the flange, and counterbores 13 are provided on 3 of the mounting holes, which are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com