Auxiliary cathode tube of double-glow penetrating metal source electrode

An auxiliary cathode and metal infiltration technology, which is applied in the direction of metal material coating process, ion implantation plating, coating, etc., can solve the problems of increasing resource consumption and labor costs, uneven temperature, and uneven distribution of infiltrated elements. Achieve the effect of saving cleaning time and resources, increasing sputtering area and reducing melting phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

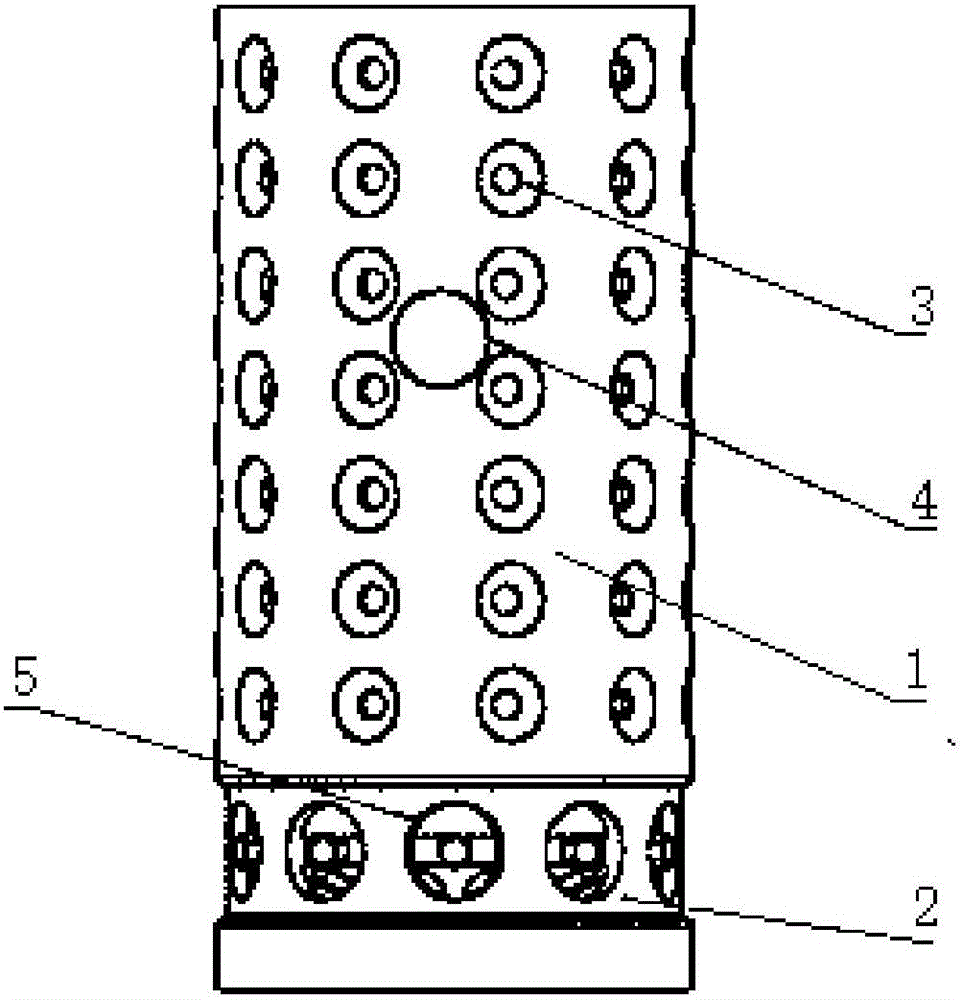

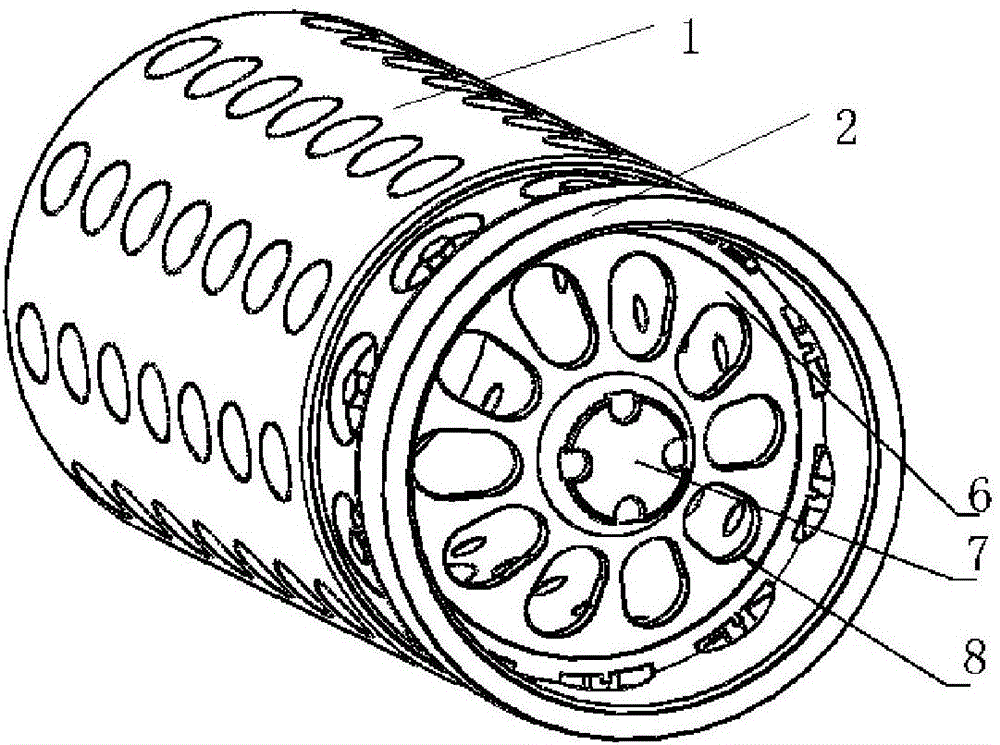

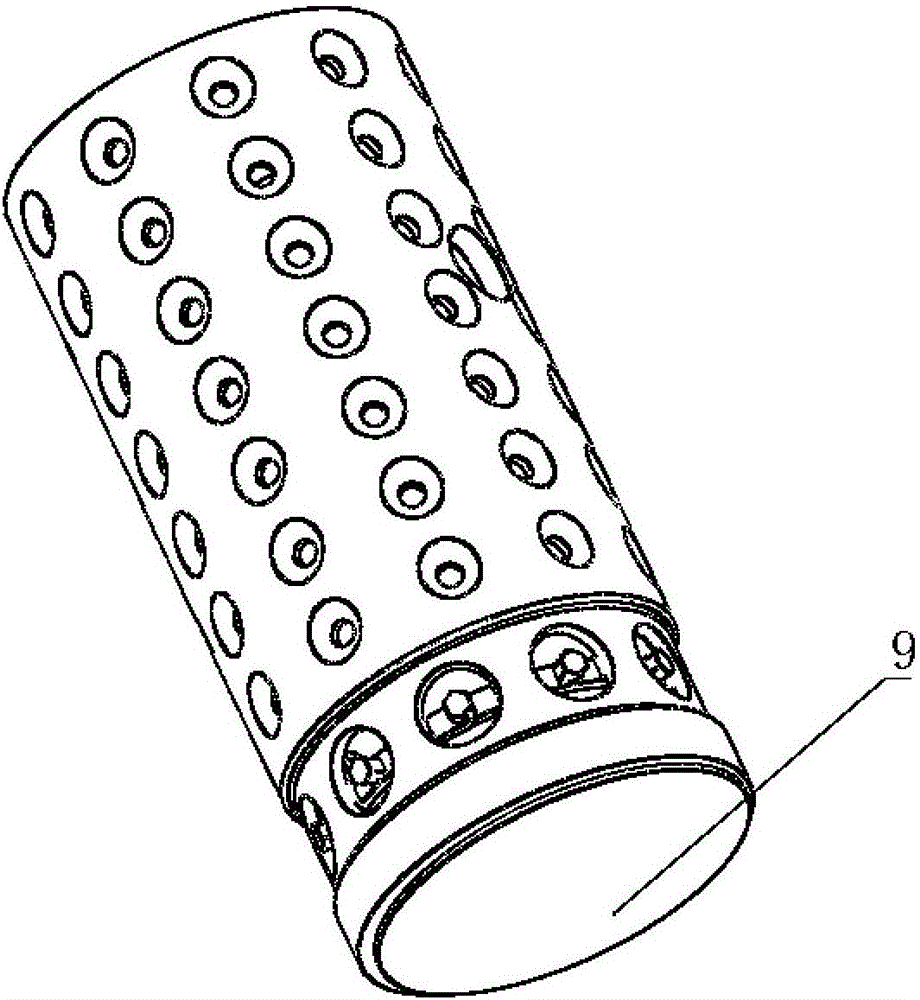

[0026] Such as Figure 1-3 Shown is a schematic diagram of the auxiliary cathode cylinder. The auxiliary cathode cylinder includes an integrated cylinder body 1 and a base 2, the cylinder body 1 is arranged on the upper end of the base 2; the cylinder body 1 and the base 2 have the same outline and size. The cylinder body 1 is provided with conical small holes 3 in a circular array and an observation hole 4 , and the larger end of the conical small holes 3 is located outside the cylinder body 1 . The base 2 is a hollow structure, and the bottom of the base 2 is an opening structure. A movable bottom cover is provided corresponding to the opening, and a number of cooling holes 5 are provided along the side wall of the base 2 . A chassis 6 is separated between the base 2 and the cylinder body 1; a groove 7 is provided on the chassis 6 at one side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com