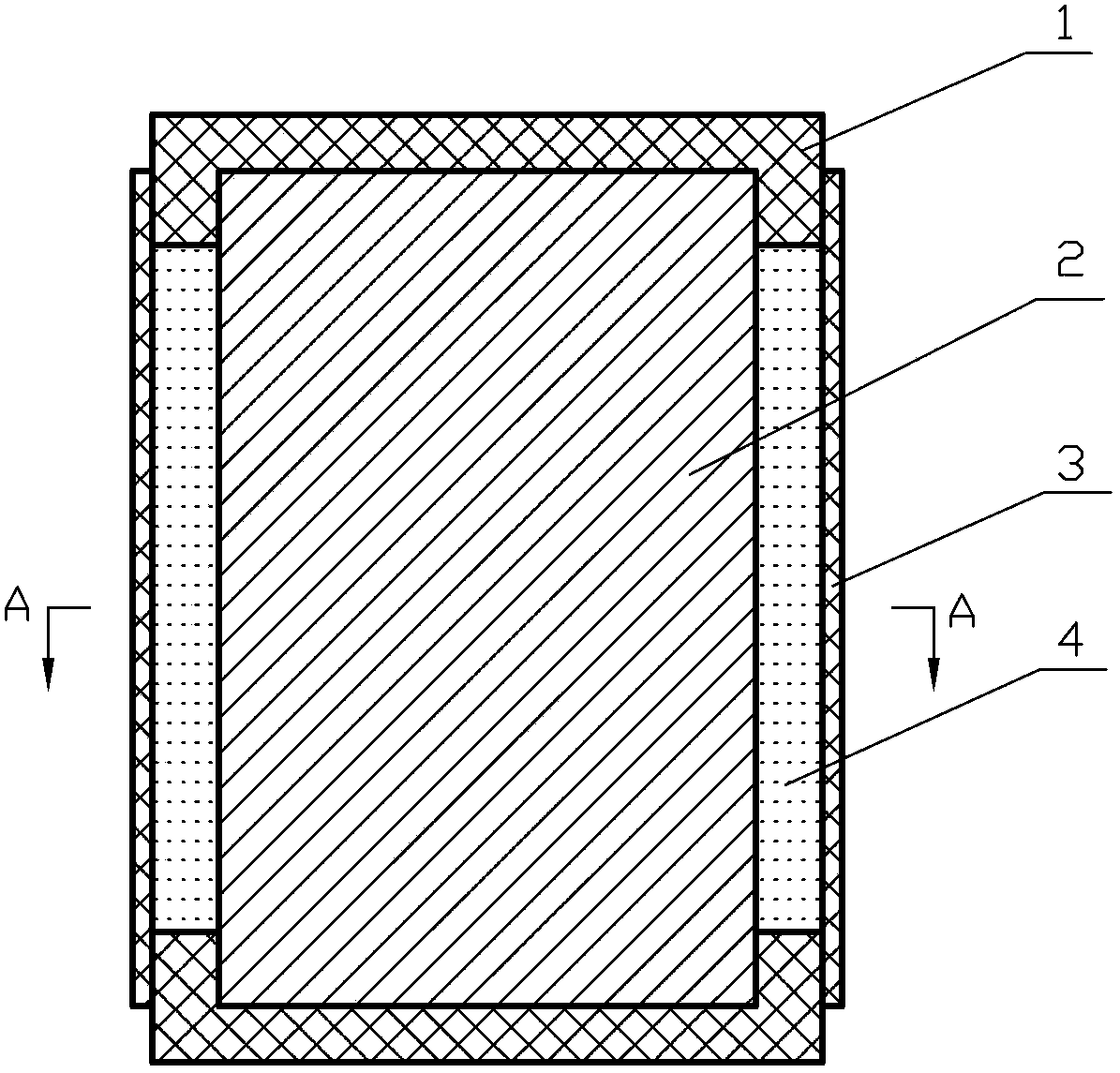

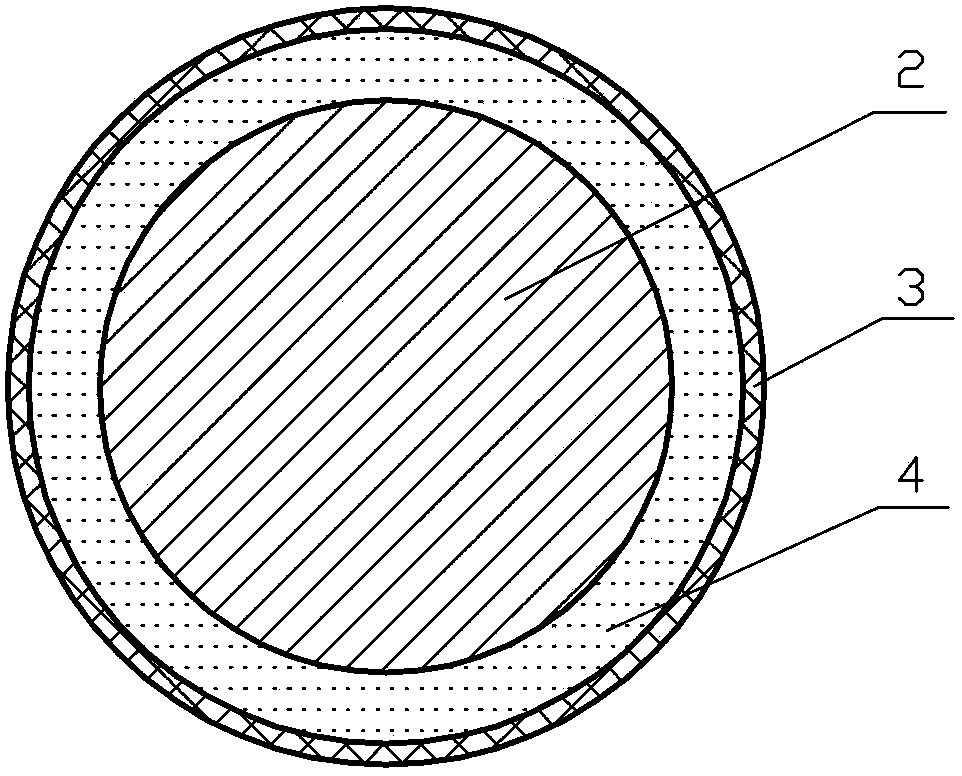

Preparation method of indium tin oxide rotary target material

The technology of indium tin oxide and rotating target is applied in the field of preparation of indium tin oxide rotating target material, which can solve the problems of difficult control of film deposition thickness uniformity, poor etching target material uniformity, low target material utilization rate, etc., and achieves unique Superiority, good uniformity and high target utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put the indium tin oxide powder obtained by the chemical co-precipitation method (the mass percentage of tin oxide is 10%, the purity of the indium tin oxide powder is more than 99.99%), put it into a tubular flexible mold, seal it and put it into cold isostatic pressing In the equipment, the cold isostatic pressing is performed at a pressure of 300MPa. After the cold isostatic pressing is completed, the pressure relief and pressure holding operation is performed. During the pressure relief and pressure holding, there are six stages of pressure relief. The second stage releases the pressure to 200MPa and holds the pressure for 1 minute, the third stage releases the pressure to 150MPa and holds the pressure for 1 minute, the fourth stage releases the pressure to 100MPa and holds the pressure for 1 minute, the fifth stage releases the pressure to 50MPa and holds the pressure for 1 minute, the sixth stage Release the pressure to 25MPa and keep the pressure for 1 minute, and...

Embodiment 2

[0022] Put the indium tin oxide powder obtained by the chemical co-precipitation method (the mass percentage of tin oxide is 2%, the purity of the indium tin oxide powder is more than 99.99%), put it into a tubular flexible mold, seal it and put it into cold isostatic pressing In the equipment, the cold isostatic pressing is performed at a pressure of 200MPa. After the cold isostatic pressing is completed, the pressure relief operation is performed. During the pressure relief, there are four stages of pressure relief. Keep the pressure at 90MPa for 1 minute, release the pressure at the third stage to 65MPa and hold the pressure for 1 minute, release the pressure at the fourth stage to 40MPa and hold the pressure for 1 minute, and finally return to normal pressure, and take out the formed green body. Then put the indium tin oxide tubular green body into the degreasing furnace, raise the temperature to 500°C at a rate of 0.2°C / min, keep it warm for 2 hours, and then drop it to ro...

Embodiment 3

[0024] Put the indium tin oxide powder obtained by the chemical co-precipitation method (the mass percentage of tin oxide is 5%, the purity of the indium tin oxide powder is more than 99.99%), put it into a tubular flexible mold, seal it and put it into cold isostatic pressing In the equipment, the cold isostatic pressing is performed at a pressure of 250MPa. After the cold isostatic pressing is completed, the pressure relief and pressure maintenance operation is performed. During the pressure relief and pressure maintenance, there are five stages of pressure relief. The second stage releases the pressure to 140MPa and holds the pressure for 6 minutes, the third stage releases the pressure to 90MPa and holds the pressure for 3 minutes, the fourth stage releases the pressure to 50MPa and holds the pressure for 2 minutes, the fifth stage releases the pressure to 25MPa and holds the pressure for 1 minute, and finally returns to normal Press, and take out the formed biscuit. Then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com