Metal ion source and application and use method thereof

A metal ion source and ion technology, applied in the field of metal ion sources, can solve the problems of limited wall thickness of the cathode tube, lack of metal ions, and small sputtering area, so as to avoid large-area discharge, improve the bonding force of the film base, and prevent sputtering. The effect of large shot area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

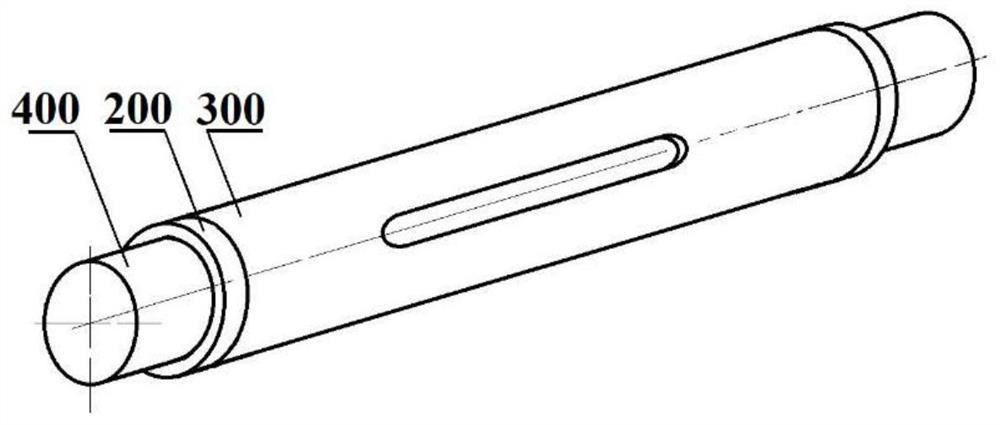

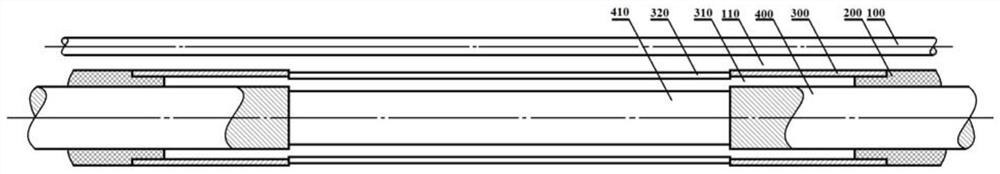

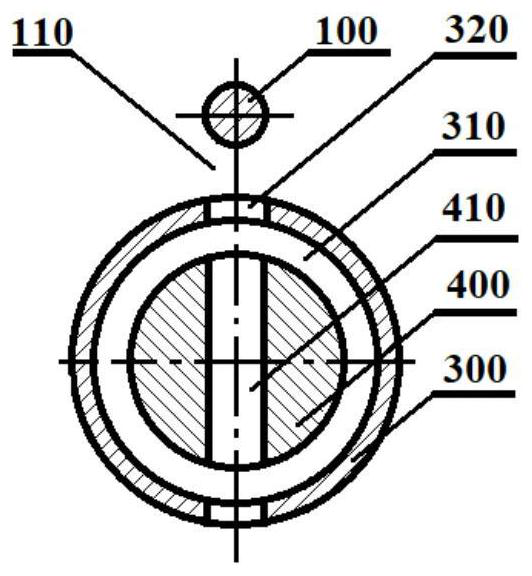

[0057] refer to figure 1 , figure 2 and image 3 As shown, the present embodiment provides a source of metal ions. It includes an outer core 100 serving as an anode, an insulating base 200 , a shield tube 300 and a cathode 400 . Wherein, the shielding tube 300 is arranged around the outside of the cathode (inner core) 400, and the cathode 400 is provided with a through hole 410 with a width of 5-10mm.

[0058] refer to figure 2 and image 3 As shown, the shielding tube 300 is arranged between the cathode 400 and the outer core 100, the inner peripheral wall of the shielding tube 300 and the outer peripheral wall of the cathode 400 form a first gap 310, and a second gap is formed between the outer peripheral wall of the shielding tube 300 and the outer core 100 110.

[0059] Two ion passage holes 320 are opened on the side wall of the shielding tube 300; among them, the through hole 410 and the ion passage hole 320 have the same shape, the same axial size, and the same ...

Embodiment 2

[0075] This embodiment provides a titanium ion source, and the only difference from Embodiment 1 is that the through hole 410 and the ion through hole 320 of the titanium ion source in this embodiment are all set as spiral holes with a pitch of 150 mm along the right helical line. , The cathode 400 is made of pure titanium.

Embodiment 3

[0077] The present embodiment provides a kind of tungsten ion source, and its only difference with embodiment 1 is: refer to Figure 4 As shown, in the present embodiment, the outer core 100 is a part to be processed, which has a hole with a diameter of 100mm and a length of 3500mm, and the shielding tube 300 is a tungsten tube with an inner diameter of 80mm, a wall thickness of 3mm, and a length of 3000mm;

[0078] Four ion passage holes 320 are opened in the middle of the shielding tube 300 in the axial direction, each ion passage hole 320 is 8mm wide and 2000mm long, and is evenly arranged along the circumference;

[0079] The cathode 400 is made of a tungsten rod with a diameter of 72 mm and a length of 3000 mm. Two through holes 410 are uniformly arranged in the middle of the cathode 400. Each through hole 410 is 8 mm wide and 2000 mm long, and is evenly arranged along the circumference. The angle between the two through holes 410 is 90 degrees. After the two ends of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com