Positive electricity colored carbon powder for electronic photographing and preparation method thereof

An electrophotographic, positively charged technology, which is applied in the field of electrophotographic positively charged color toner and its preparation, can solve the problems of blurred characters and images, powder drop, can not completely solve the problems of the charging stability of color toner particles, etc. Improves cleanliness and power stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

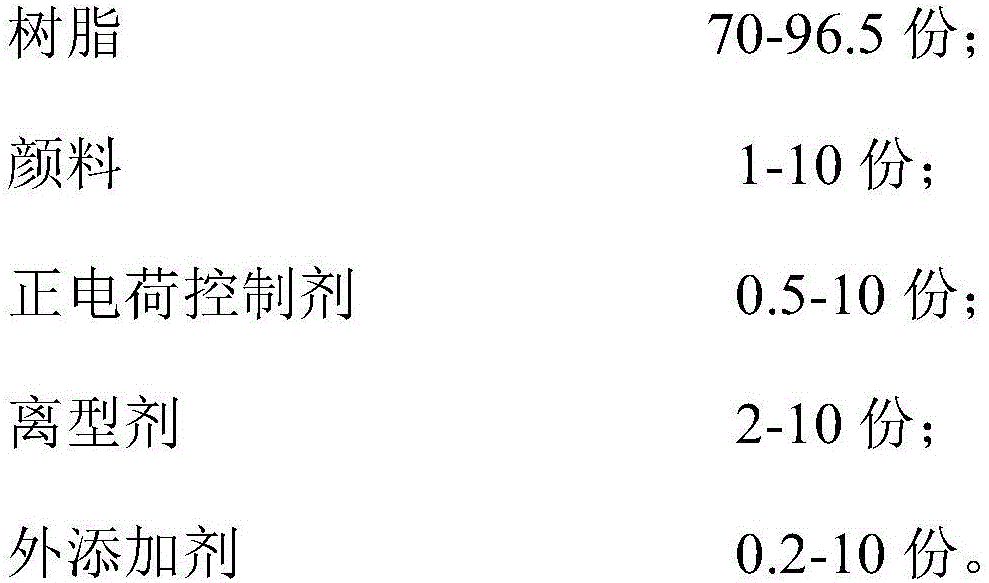

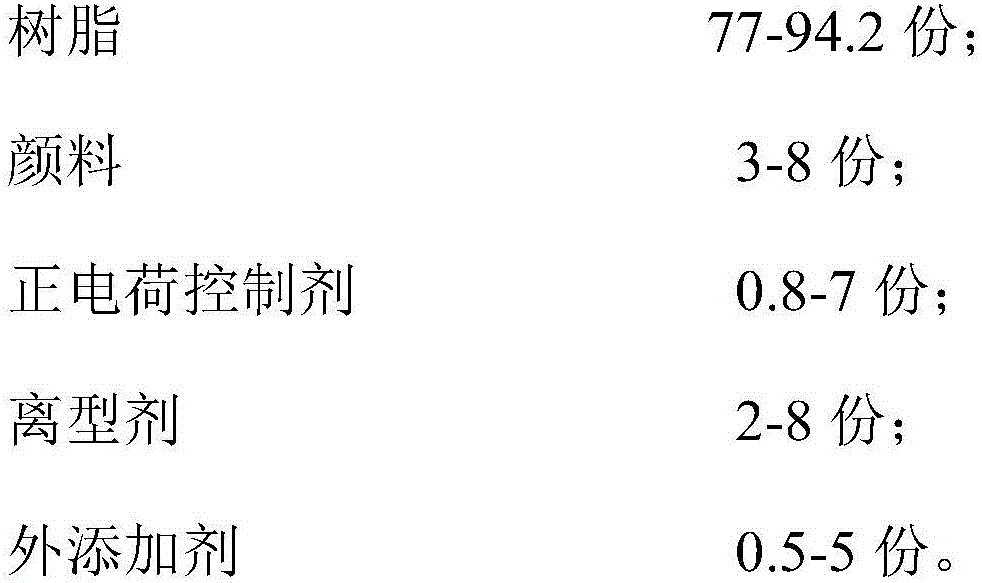

Method used

Image

Examples

Embodiment 1

[0026] The preparation of cyan toner comprises the following two steps:

[0027] 1) Preparation of carbon powder semi-finished products: 905 parts of ET8100 polyester resin (produced by SK Chemicals in South Korea, softening point 155°C, glass transition temperature 66°C), add 50 parts of cyan pigment PV Fast Blue BG (produced by Clariant, Germany), add 10 Parts of positive charge control agent P51 (produced by Dongfang Chemical in Japan) and 35 parts of polyethylene wax POLYWAX 2000 (produced by Baker Hughes in the United States, melting point 126 ° C), in a 5L high-speed mixer produced by Zhangjiagang Baixiong Machinery Co., Ltd. at a peripheral speed of 20m / s mixed for 5 minutes, and the obtained mixture was kneaded in Nanjing Chengmeng co-rotating twin-screw extruder (TSH-25), the extrusion temperature was 135°C, after cooling, it was coarsely pulverized on a hammer mill, and then used in a Shanghai chemical machine The 100-type airflow pulverizer of the third factory is ...

Embodiment 2-6

[0030] The difference between the following examples and Example 1 is that the proportions of different positively charged silicon dioxide and negatively charged silicon dioxide in the external additives are different, and the particle size and charge amount are also different, as shown in Table 1.

[0031] The composition of external additive in table 1 embodiment 2-6

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com