Blast furnace multi-element molten iron quality prediction control method and system

A quality prediction and control method technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of effective control of difficult multi-element molten iron quality indicators, high degree of nonlinearity, and various types of raw materials and fuels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

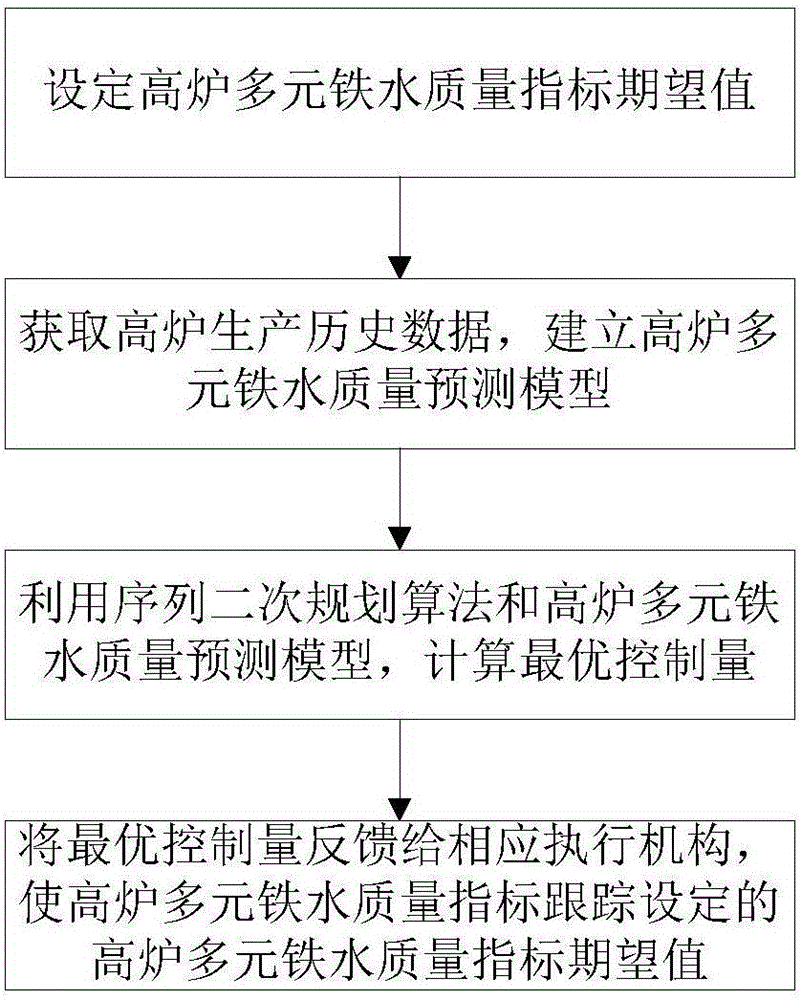

[0073] A method for predicting and controlling the quality of blast furnace multi-element molten iron, such as figure 1 shown, including:

[0074] Step 1, setting the expected value of the multi-element molten iron quality index of the blast furnace, the multi-element molten iron quality index includes silicon content, molten iron temperature;

[0075] Step 2. Obtain the historical data of blast furnace production, and establish a blast furnace multi-element molten iron quality prediction model. The model takes hot blast temperature, hot air pressure, oxygen enrichment rate, and set coal injection amount as input, and multi-output multi-element molten iron quality index as output Least squares support vector regression model;

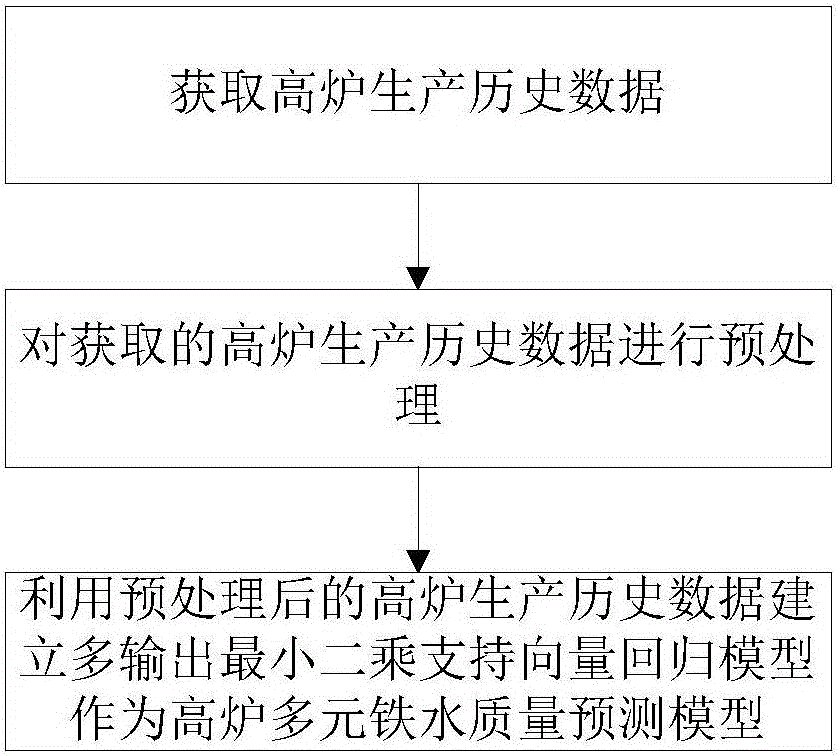

[0076] Such as figure 2 As shown, the step 2 includes:

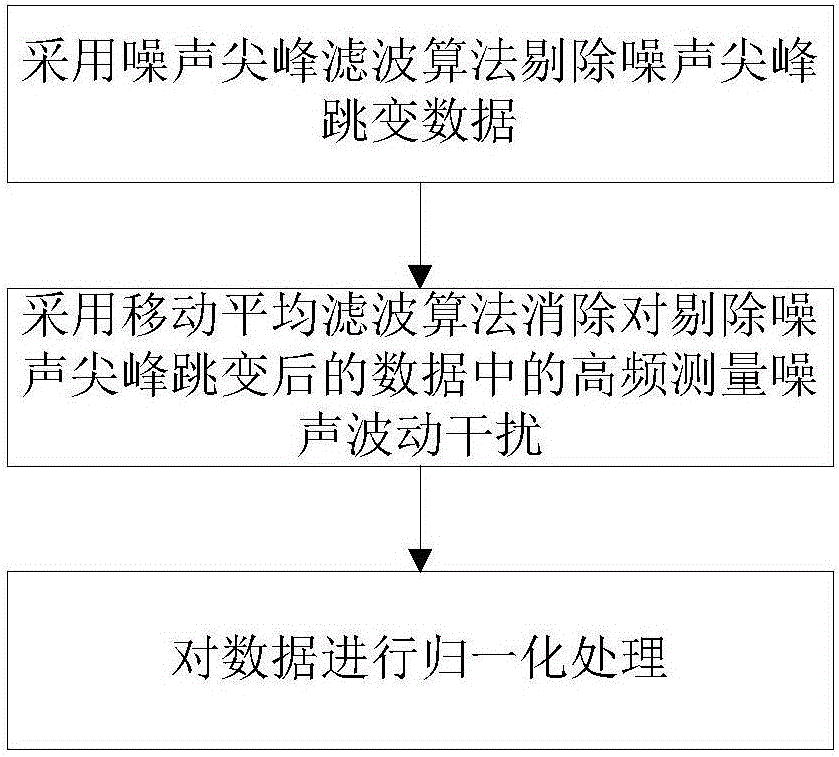

[0077] Step 2-1, obtaining the historica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com