Fault management method based on Modelica model

A fault management and fault technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems that the types of faults cannot be defined according to the requirements, the fault management methods cannot be unified, and the dynamic attributes of the system cannot be reflected. Reaching the effect of reliable fault management method, shortening construction period and shortening development time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be further described below in conjunction with example, but does not limit the present invention.

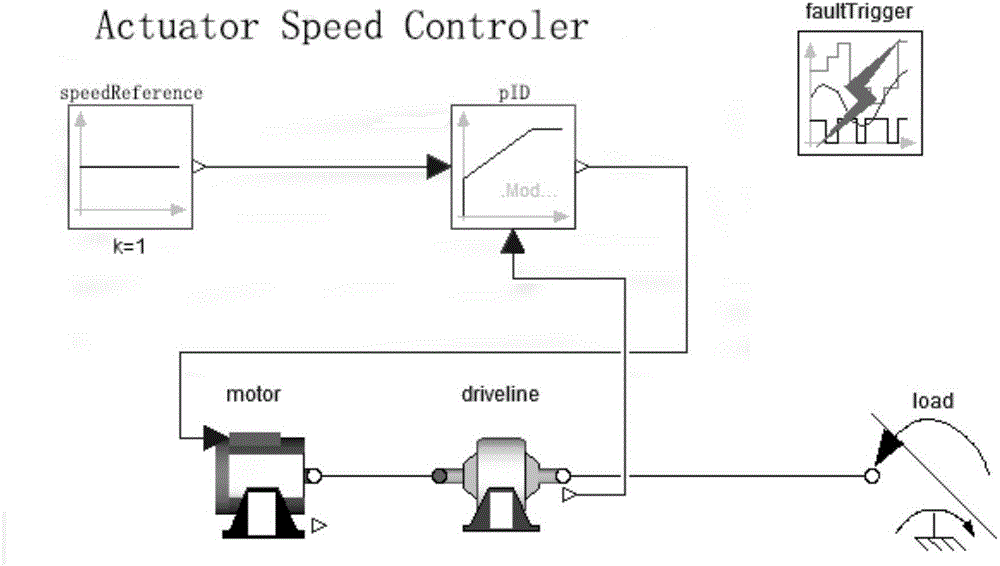

[0086] This example is the Modelica model of the motor drive system ( Image 6 ), implemented on Dymola's operating platform.

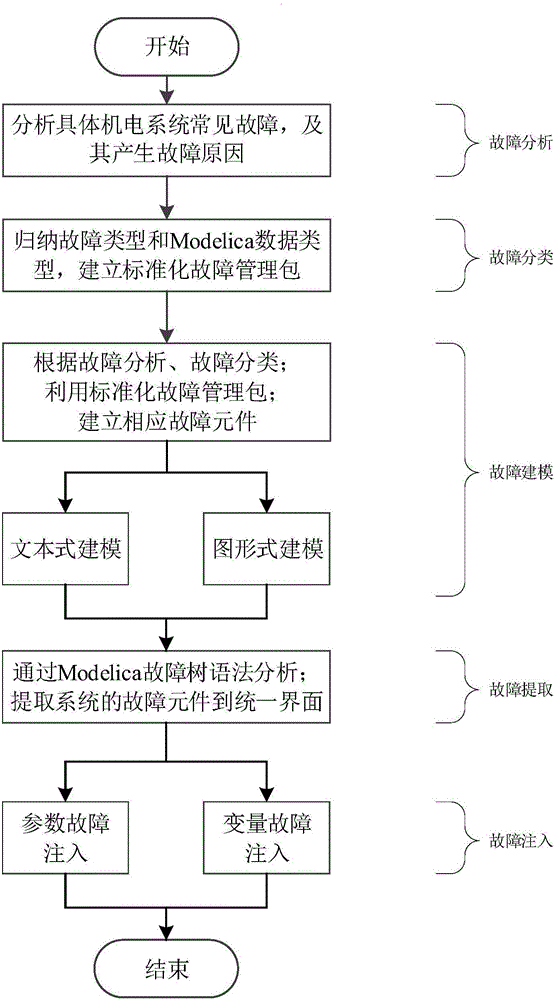

[0087] A kind of fault management method based on Modelica model of the present invention, see figure 1 As shown, the specific steps of its implementation are as follows:

[0088] Step 1: Failure Analysis. Aiming at the specific Modelica model of the electromechanical system, the common faults and the causes of the faults are analyzed, and the possible fault items of the electromechanical system are obtained. Possible failure items in the example are:

[0089] 1) The brake pads of the transmission module are not in contact.

[0090] 2) Fault of change of friction force of transmission module brake pads

[0091] 3) Transmission module bearing failure mode failure

[0092] 4) Transmission module sensor failure fau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com