Weak-texture workpiece, and method and system for recognizing and detecting three-dimensional pose

A detection method and a technology of three-dimensional pose, which is applied in character and pattern recognition, image data processing, computer parts, etc., can solve the problems of complex data acquisition and processing, inability to obtain accurately, high application scenarios, etc., and achieve the improvement of three-dimensional pose Estimation accuracy, interference avoidance, and simple system construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

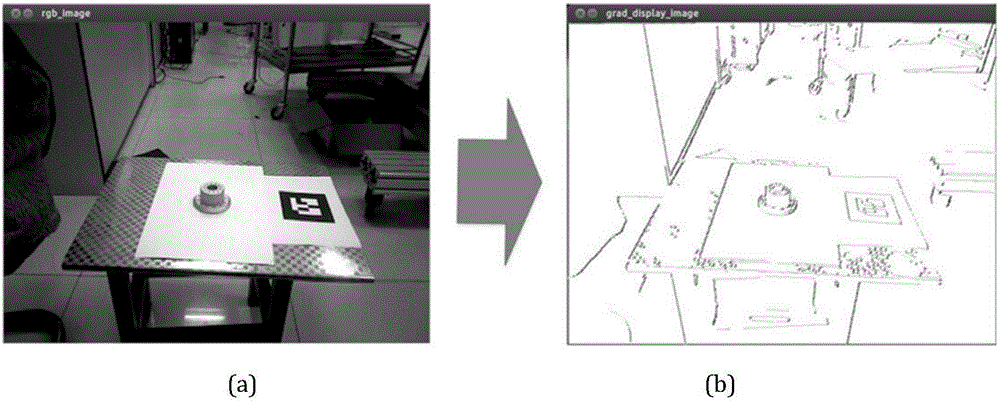

[0025] This embodiment relates to a recognition and detection system for a weak texture workpiece and its three-dimensional pose, including: a vision sensor module, a recognition module, and a control module. The vision sensor module outputs the color image of the target workpiece and the corresponding depth image to the transmission To the recognition module, the recognition module generates a series of templates according to the built-in 3D model of the target workpiece, and transmits the detected 3D pose information of the target workpiece to the control module. The control module converts the 3D pose information of the target workpiece into absolute and / or relative Coordinate system and generate operation instructions to achieve precise operation.

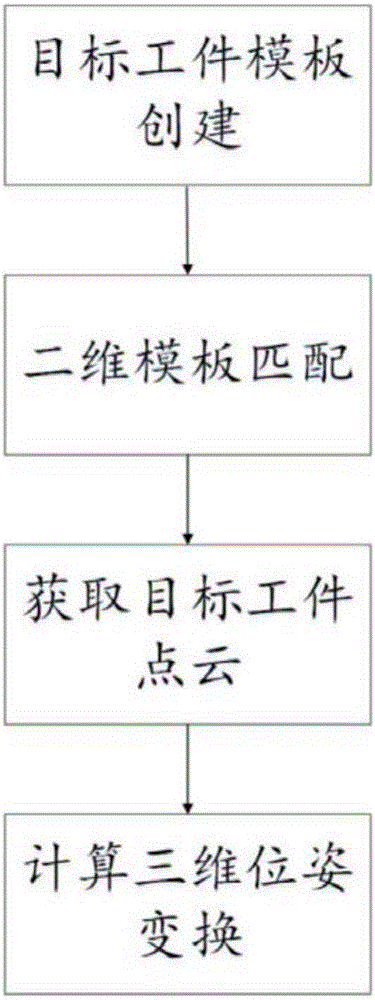

[0026] Such as figure 1 As shown, the method for recognizing a weakly textured workpiece and estimating a three-dimensional pose provided by this embodiment includes four steps: target workpiece template creation, two-dimensional t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com